Key functions for 5-axis machining

3.7

© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

74

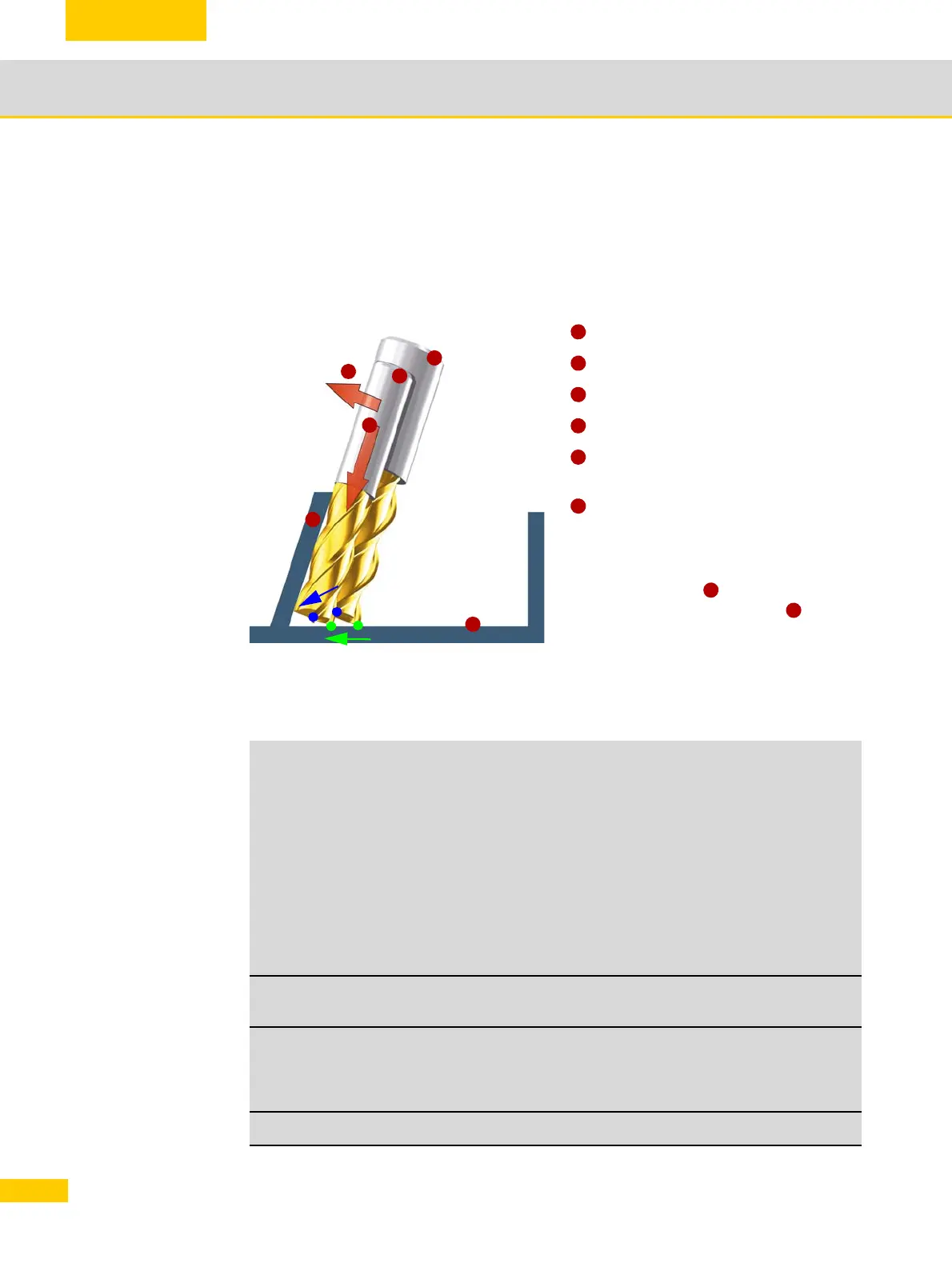

Influence of tool radius compensation with 5-axis circumferential milling, taking

into account the limitation surface (CUT3DCC)

Imagine that a pocket needs to be created using a smaller milling cutter. The side wall is not per-

pendicular to the floor surface. The control supports tool radius compensation with a smaller tool.

A typical application involving this function relates to structural components within the aviation

industry.

Circumferential milling

Explanation of the commands

Standard tool (tool from CAM)

Tool with smaller radius

Machining surface, inner surface

Limitation surface of pocket floor

Compensation in relation to machining

surface

Compensation in relation to limitation sur-

face

The control recognizes the fact that it is not

just a question of compensating in the machin-

ing surface direction , but also of making

an adjustment in the tool direction , so that

the point of action (green) is at the same level

as the pocket floor. This results in a shift in the

TCP (blue) in the direction of the pocket floor.

G40 Deactivation of all variants

G41 Activation for circumferential milling, compensation direction left

G42 Activation for circumferential milling, compensation direction right

G450 Circles at external corners (all compensation types)

G451 Intersection method at external corners (all compensation types)

2 ½D circumferential milling

CUT2D 2 1/2D COMPENSATION with compensation plane determined

using G17 – G19

CUT2DF 2 1/2D COMPENSATION with compensation plane determined

using a frame

3D circumferential milling

CUT3DC Compensation perpendicular to path tangent and tool orientation

1

2

3

5

6

4

1

2

3

4

5

6

5

6

Loading...

Loading...