Operating Manual SIGMA 2-16P page 52 of 75

04/2007

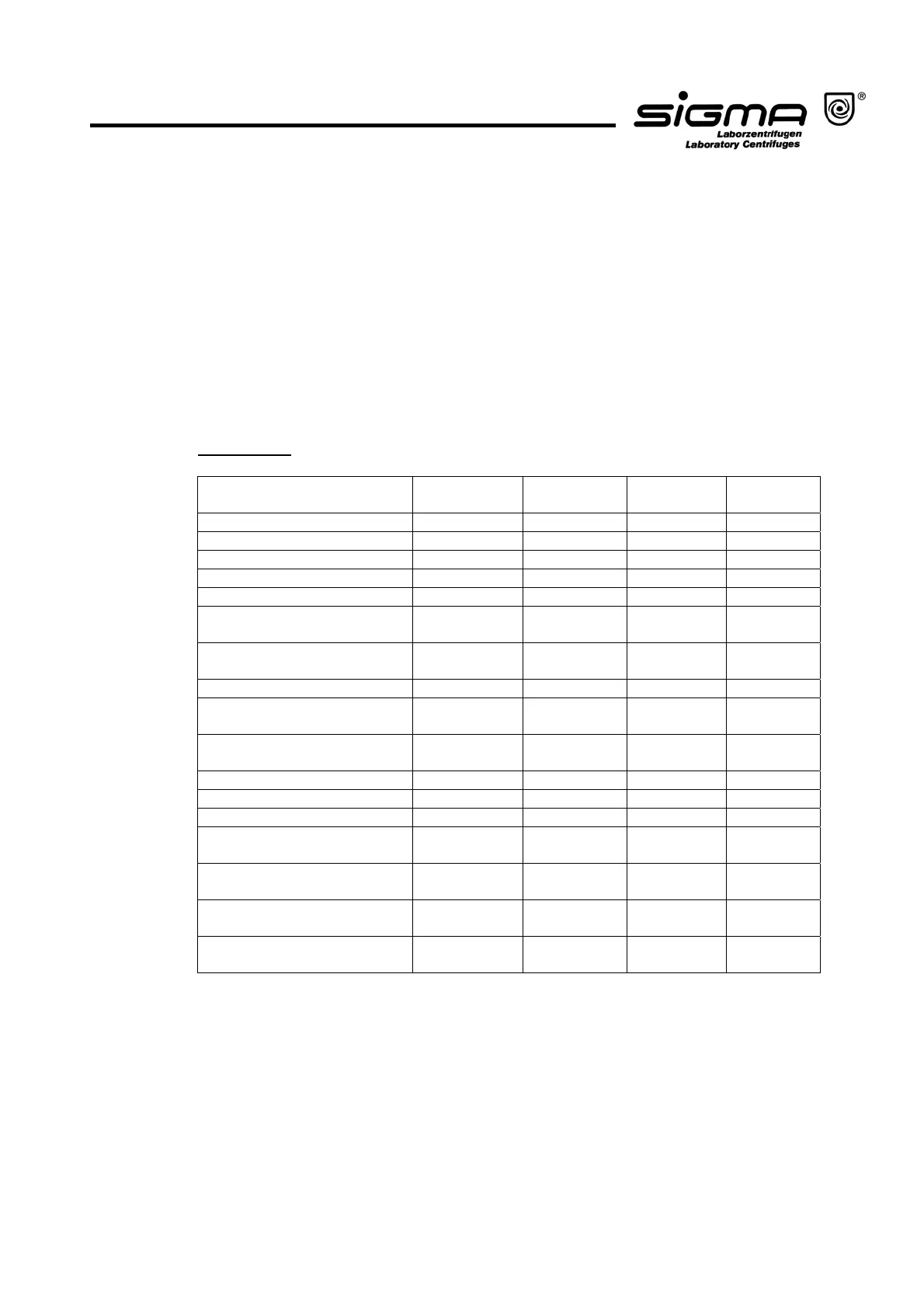

7.2.1 Autoclaving

The service life of the accessories essentially depends on the frequency of

autoclaving and use.

• Replace the accessories immediately when the parts show changes in color

or structure or in the occurrence of leaks etc.

• During autoclaving, the caps of the tubes must not be screwed on in order to

avoid the deformation of the tubes.

It cannot be excluded that plastic parts, e.g. lids or carriers, may deform during

autoclaving.

Autoclaving:

Accessories max. temp.

°C

min. time

min

max. time

min

max.

cycles

Glass tubes 134-138 3 40 -

Polycarbonate tubes 115-118 30 40 20

Polypropylene tubes 115-118 30 40 30

Teflon tubes 134-138 3 5 100

Aluminum rotors 134-138 3 5 -

Polycarbonate/Polyallomer

lids for angle rotors

115-118 30 40 20

Polysulfone lids for angle

rotors

134-138 3 5 100

Aluminum buckets 134-138 3 5 -

Polycarbonate caps for

buckets

115-118 30 40 50

Polypropylene caps for

buckets

115-118 30 40 50

Polysulfone caps for buckets 134-138 3 5 100

Rubber adapters 115-118 30 40 -

Rubber cushions 115-118 30 40 -

Round carriers made of

polypropylene

115-118 30 40 -

ditto, made of polyallomer

and polycarbonate

115-118 30 40 -

Rectangular carriers made of

polypropylene

115-118 30 40 -

ditto, made of polyallomer

and polycarbonate

115-118 30 40 -

Fi

. 7.1: Autoclavin

table

Loading...

Loading...