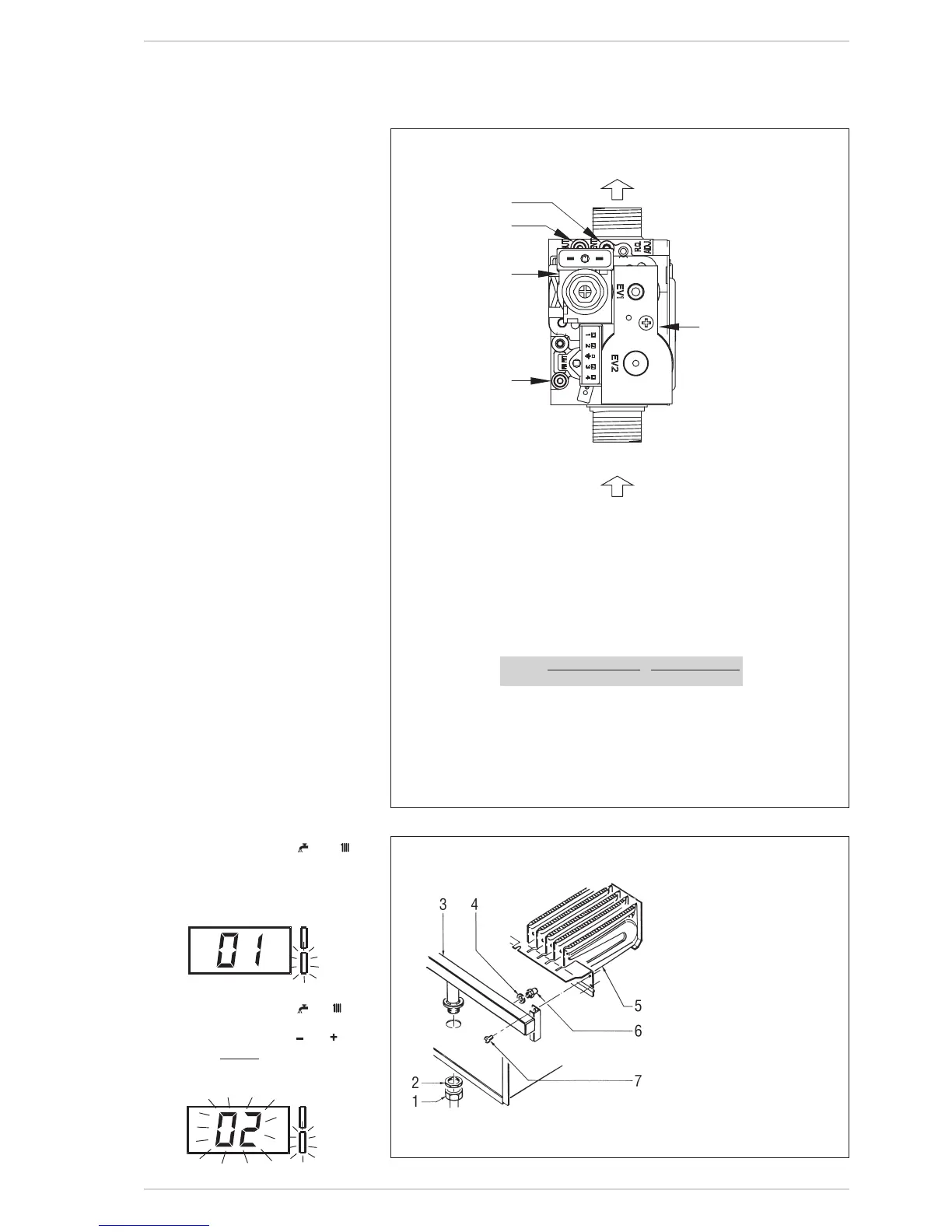

6.4.1 GAS VALVE

The boilers are equipped standard with

theSIT845SIGMAgasvalve(fig.22).

The gas valve is set at two pressure

values:maximumandminimum.

Accordingtothetypeofgasburnt,these

correspondto thevaluesgiven inTable

4.

The gas pressures at the maximum

and minimum values, are factory set.

Consequentlytheymustnotbealtered.

The gas valve will require resetting on

conversion to another gas(Natural gas

toLPG).

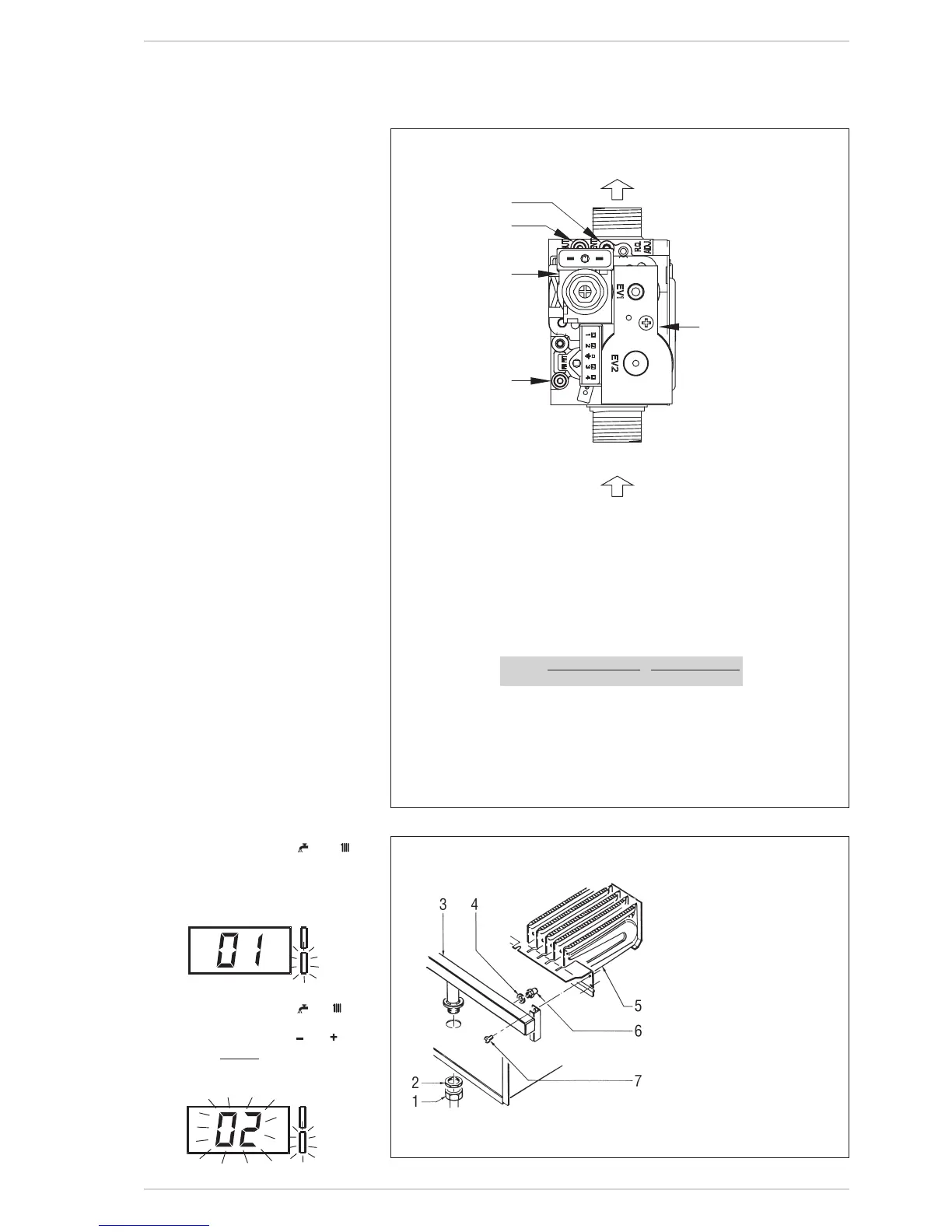

6.4.2 GAS CONVERSION

This operation must be performed by

authorised personnel using original

Sime components.

To convert from natural gas to LPG or

viceversa,performthefollowingopera-

tions(fig.23):

– Close the gas cock and isolate the

boilerselectricalsupply.

– Disassembletheburnermanifold(3).

– Replacethemainnozzles(6)supplied

in a kit, inserting the copper washer

(4).Useaø7spannertoperformthis

operation.

– Configurethenewfuelasindicatedin

point6.4.2.1

– For calibrating the maximum and

minimum gas pressure values, see

point6.4.2.2.

–Fixthelabeltothedataplateshowing

theNewgasconfiguration.

NOTE: Ensure that on reassembly all

seals are replaced as require, and the

tightness tested, using a suitable leak

detection fluid.

6.4.2.1 New fuel configuration

Accesstheparameterssectionbypres-

singthecontrolpanelkeys(

Fig.23

KEY

1 Swivelconnection1/2”

2 Locknut1/2”

3 Burnermanifold

4 Washerø6.1

5 Burners

6 NozzleM6

7 Screw

WARNING: To ensure a perfect

seal, always use the washer (4)

supplied in the kit when repla-

cing nozzles, even in burner

units for which it is not speci-

fied.

Fig.22

KEY

1 Modulator

2 EV1-EV2coils

3 Pressureinletupstream

4 Pressureinletdownstream

5 VENTpressure

TABLE 4

Output BurnerpressurekPa ModulatorcurrentmA

NG LPG NG LPG

Maximum 0,85 2,50 130 165

Minimum 0,04 0,33 0 0

Loading...

Loading...