The boiler must be installed in a fixed

locationandonlybyauthorisedperson-

nel in compliance with all instructions

containedinthismanual.

Furthermore, the installation must be

inaccordancewith currentStandardAS

5601andotherregulationsasapplicable.

Use the template supplied to position

allholes.

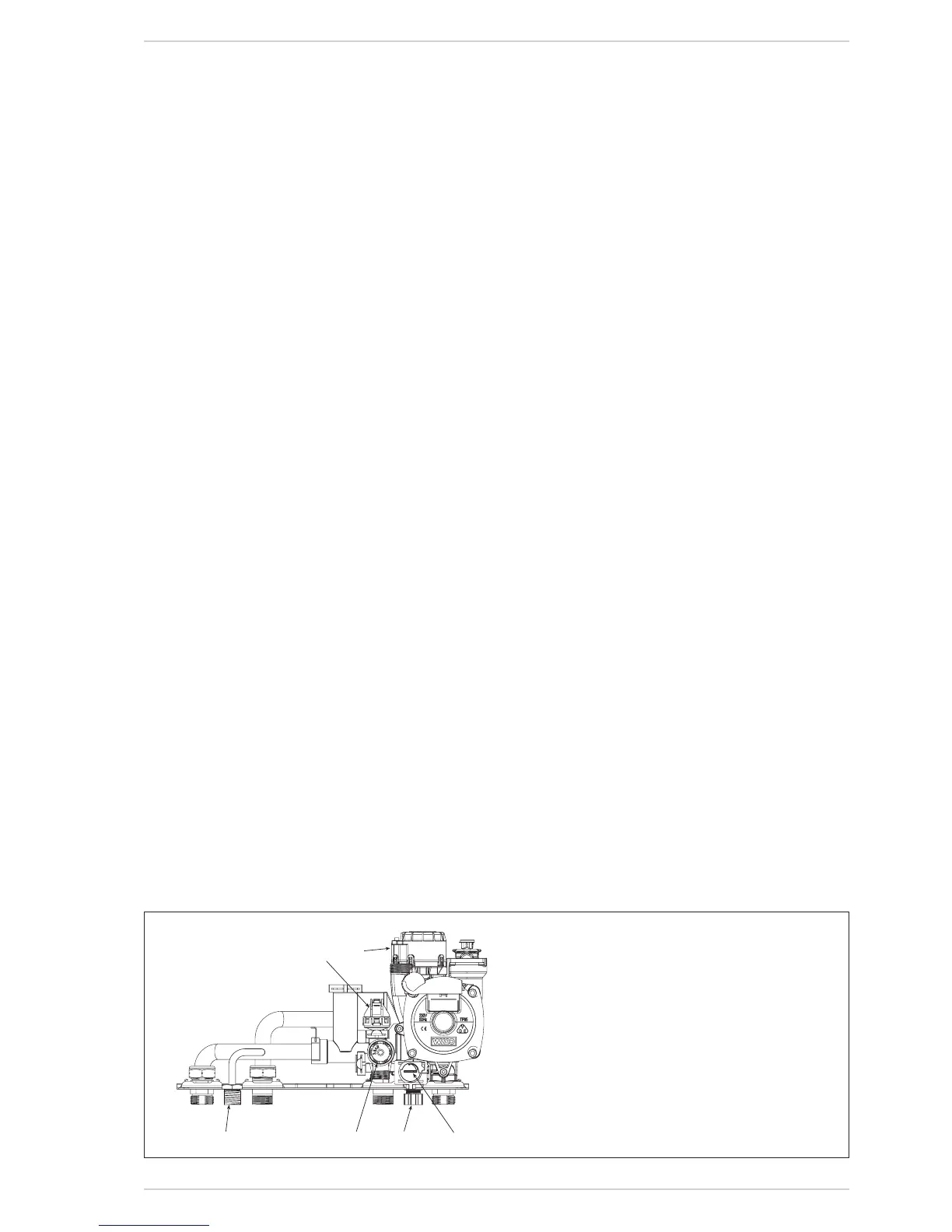

6.2.1 INSTALLATION

– Theseboilerscanbeinstalledinallnormal

domestic environments as aroomsealed

multifunctionboiler.

–

These boilers can also be installed in

partiallycovered areas,asper AS5601,

with a maximum ambient temperature

of60°Candaminimumambienttempe-

ratureof-5°C.Itisgenerallyadvisable

to install the boilers below weathered

roofs, on the balcony or in a protected

niche,toprotectthemfromexposureto

weatheringagents(rain,hailandsnow).

Allboilersprovideastandardantifreeze

function.

MINIMUMCLEARANCES

forINTERNALBOILERS

This Boiler must have the following cle-

arances:

Above200mm

Below200mm

Sides 50mm

Front 600mm

Min50mmtoanopenablepanel.

6.2.1.1 Anti-freeze function

The boilers are equipped with anti-fre-

eze function which activates the pumps

andtheburnerwhenthetemperatureof

thewatercontained insidethe appliance

drops to below value PAR 10. The anti-

freezefunctionisensured,however,only

if:

– theboileriscorrectlyconnectedtothe

gasandelectricitysupplycircuits;

– theboilerisconstantlyfed;

– theboilerignitionisnotlockedout;

– theessentialcomponentsofthe

boilerareallinworkingorder

Intheseconditionstheboilerisprotected

against frost down to an environmental

temperatureof-5°C.

ATTENTION: In the case of installation

in a place where the temperature drops

below 0°C, the connection pipes must

be protected.

6.2.2 COMPLEMENTARY

ACCESSORIES

The fixing jig code 8075427 is supplied

onrequest.Itallowstomounttheboiler

on wall and it is completed of installing

instructions.

6.2.3

CONNECTING UP SYSTEM

Toprotectthe heat systemfrom dama-

gingcorrosion, incrustationor deposits,

beforeinstallationitisextremelyimpor-

tant to clean the system using suitable

productssuchas,forexample,FERNOX.

Completeinstructionsareprovidedwith

theproductsbut,forfurtherinformation

pleasecontacttheHuntHeatingtechni-

caldepartment.

For long-term protection agains corro-

sion and deposits, the use of inhibitors

such as Fernox is recommended after

cleaning the system. It is important to

check the concentration of the inhibi-

tor after each system modification and

duringmaintenancefollowingthemanu-

facturer’spublishedinstructions.

The safety valve drainmustbeconnec-

ted to a collection funnel to collect any

discharge during interventions. If the

heatingsystemisonahigherfloorthan

theboiler,installtheon/offtapssupplied

inkitoptionalontheheatingsystemdeli-

very/returnpipes.

WARNING: Failure to clean the heating

system or add an adequate inhibitor

invalidates the appliance’s warranty.

Gasconnectionsmustbemadeinaccor-

dancewithcurrentstandardsandregula-

tions.Whendimensioninggaspipesfrom

the meter to the module, both capacity

volume (consumption) in m

3

/h and gas

densitymustbetakenintoaccount.

The sections of the piping making up

thesystemmust besuch astoguaran-

tee a supply of gas sufficient to cover

themaximumdemand,limitingpressure

loss between the gas meter and any

apparatus being used to not greater

than:

– 1.0 mbar for family II gases (natural

gas);

– 2.0mbarforfamilyIIIgases(butaneor

propane).

An adhesive data plate is placed insi-

de the front panel; it contains all the

technical dataidentifyingthe boiler and

the type of gas for which the boiler is

arranged.

6.2.3.1 Filter on the gas pipe

Thegas valveissuppliedexfactory with

aninletfilter,which,however,isnotade-

quate to entrap all the impurities in the

gasoringasmainpipes.

Topreventmalfunctioningofthevalve,or

incertaincaseseventocutoutthesafety

device with which the valve is equipped,

installanadequatefilteronthegaspipe.

6.2.4 SYSTEM FILLING

The charge pressure, with the system

cold,mustbebetween1 and 1.2 bar.

Fillingmustbedoneslowlysoastoallow

anyairbubblestobebledoffthroughthe

airvalves.

Should the pressure have risen well

above the limit expected, discharge the

overpressure byopening thepressure-

reliefvalve.

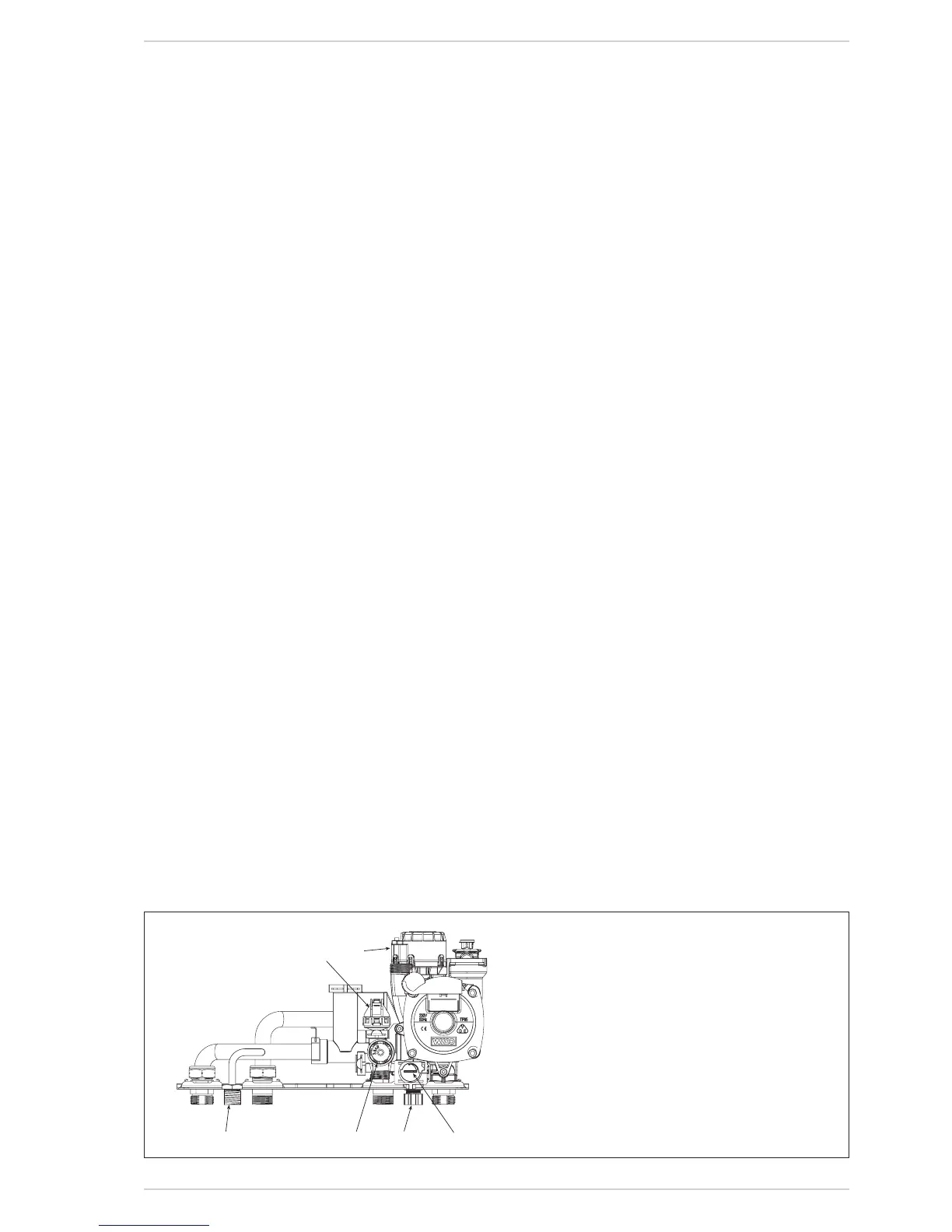

NB: In the SYSTEM version the filling is

done by the system filling connection

(item 10 fig. 8).

6.2.4.1 Emptying the system

Usethedrain ventto emptythesystem

(item5fig.8).

Turnofftheboilerbeforedoingthis.

Loading...

Loading...