300 DEFine PROCedure stop_all

310 sedes 8,0

320 END DEFine

Key-in start_mdv(n) to turn on drive number n and to keep it spinning continuously. Key-in stop_all to stop all drives spinning.

1. Start microdrive 1.

2. Using an oscilloscope, check that a signal is present from the read head (INA, IC29) and trace it through to the RAW inputs on the 8302.

3. If there is nothing coming from the head, then the head is faulty.

4. If there is an input to IC29 but no output, it suggests a faulty IC or headboard component.

5. Check the connector in the same way.

6. Carry out the same procedure on microdrive 2. If both drives appear to be working it could be that the fault lies in the 8302. Since it is a plug-

in chip it is easy to check this.

7. Check the clock signal on pin 25 of the 8302.

2.4.5 An alternative method is to use a known serviceable ZX microdrive plugged into the microdrive expansion port. This isolates faults to either

the machine or the microdrives.

2.4.6 Load and run the system test tape. Section 3, System Test, provides details on how to load this test. The following table lists possible faults

and remedies. Where it is necessary to change or adjust the position of the motor, the motor jig (Figure 4.1) must be used.

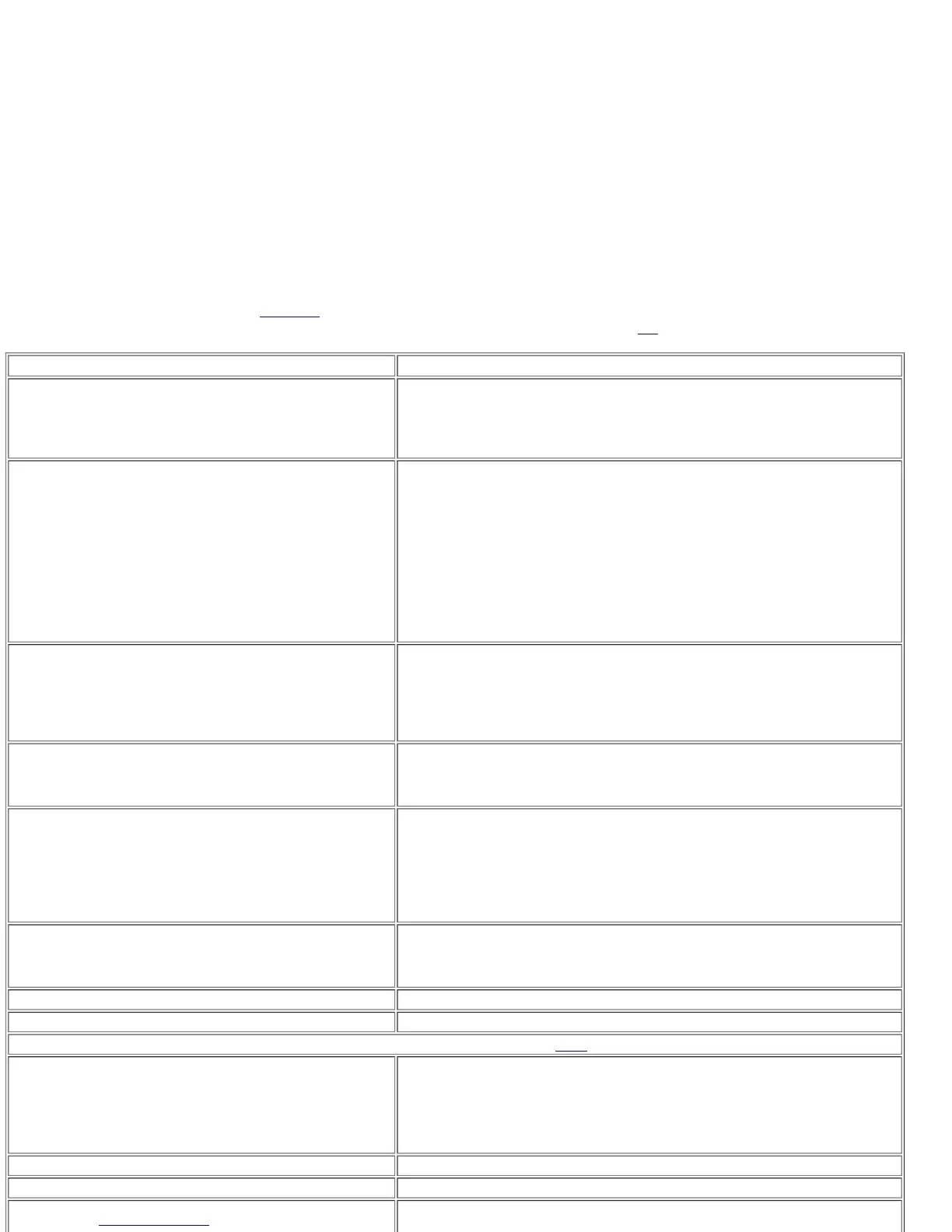

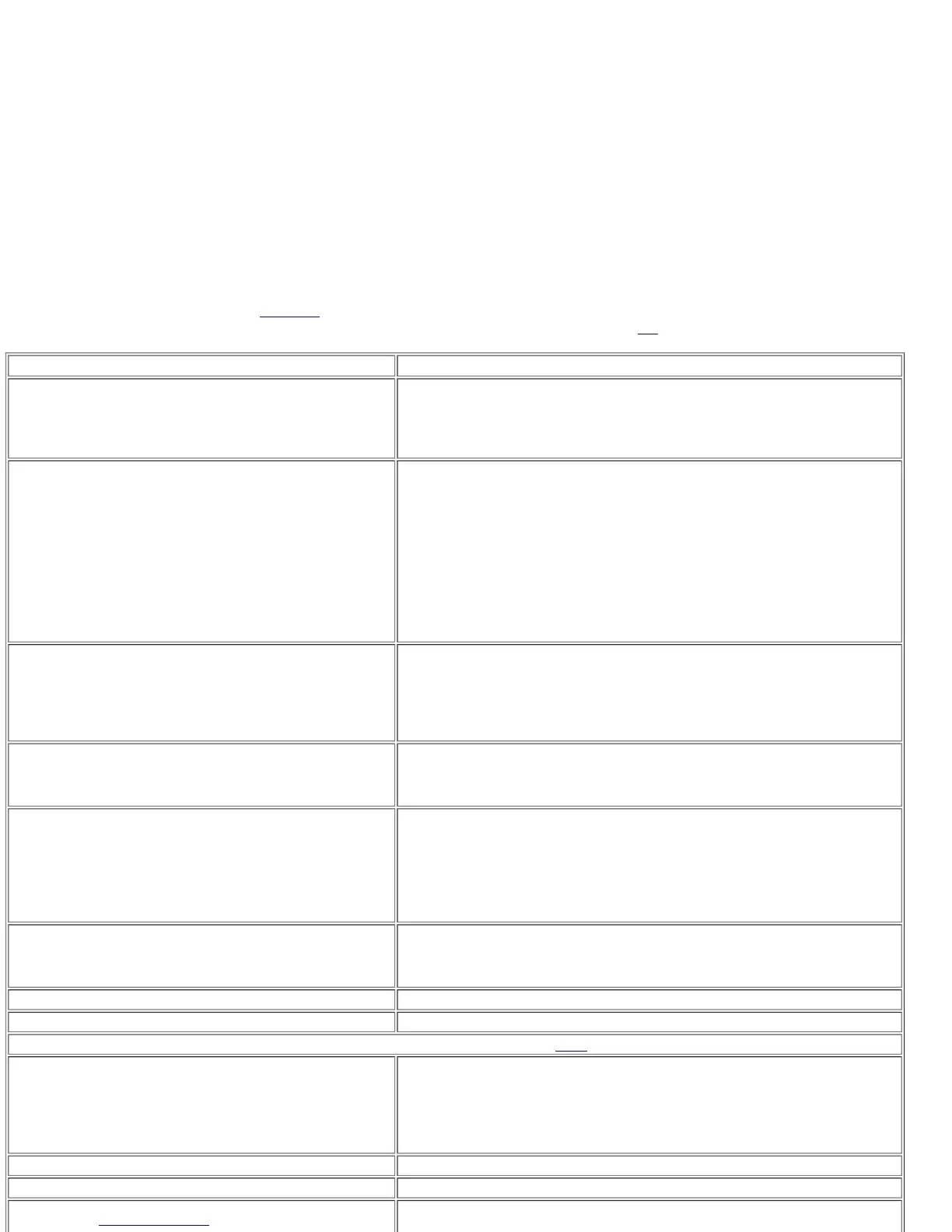

SYMPTOM REMEDY

Screen displays 'Put a blank tape in MDV1 (MDV2)' even

when tape present

1. Check/replace TR7 (TR6).

2. Replace IC30 (IC29).

Screen displays 'Failed microdrive test'

1. Check for write protect tab on cartridge.

2. Check headboard connector (HBC)1(2).

3. Check microswitch.

4. Check/adjust motor.

5. Check R35(R34), R37(R36), C16(C15), C18(C17).

6. Renew IC30(IC29).

7. Renew IC23.

8. Renew IC22.

Microdrive does not operate when selected.

1. Check TR7 (TR6), TR5 (TR4)

2. Check motor.

3. Check microdrive mechanics for:

Tight cartridge tape.

1. Weak clamp spring (listen for clicks/crunch sounds).

Noisy operation.

Fails to format.

Jammed tape.

Damaged cartridges.

Microdrive incompatibility.

2. Faulty/maladjusted rollers.

3. Adjust motor.

NOTE: If motor has over-heated, check for buckled baseplate. Renew

complete microdrive unit.

4. Check HBC1(2).

Head failure. Renew complete microdrive unit.

LED failure. Renew LED (LED is push-fitted).

Check mod state (see Section 4, para 1.2.2)

Unreliable loading/saving, machine locking-up.

1. Renew IC30 (IC29).

2. Renew IC23,

3. Check motor position and roller.

Continuous running MDV1(MDV2). Renew TR7(TR6)

MDVs do not activate. Renew IC23.

Loading...

Loading...