POSITIONING

NEEDLE

IN

RELATION

TO

THROAT

PLATE

AND

FEED

DOG (MACHINES

281-22

AND 281-24)

NEEDLE

HOLE

V

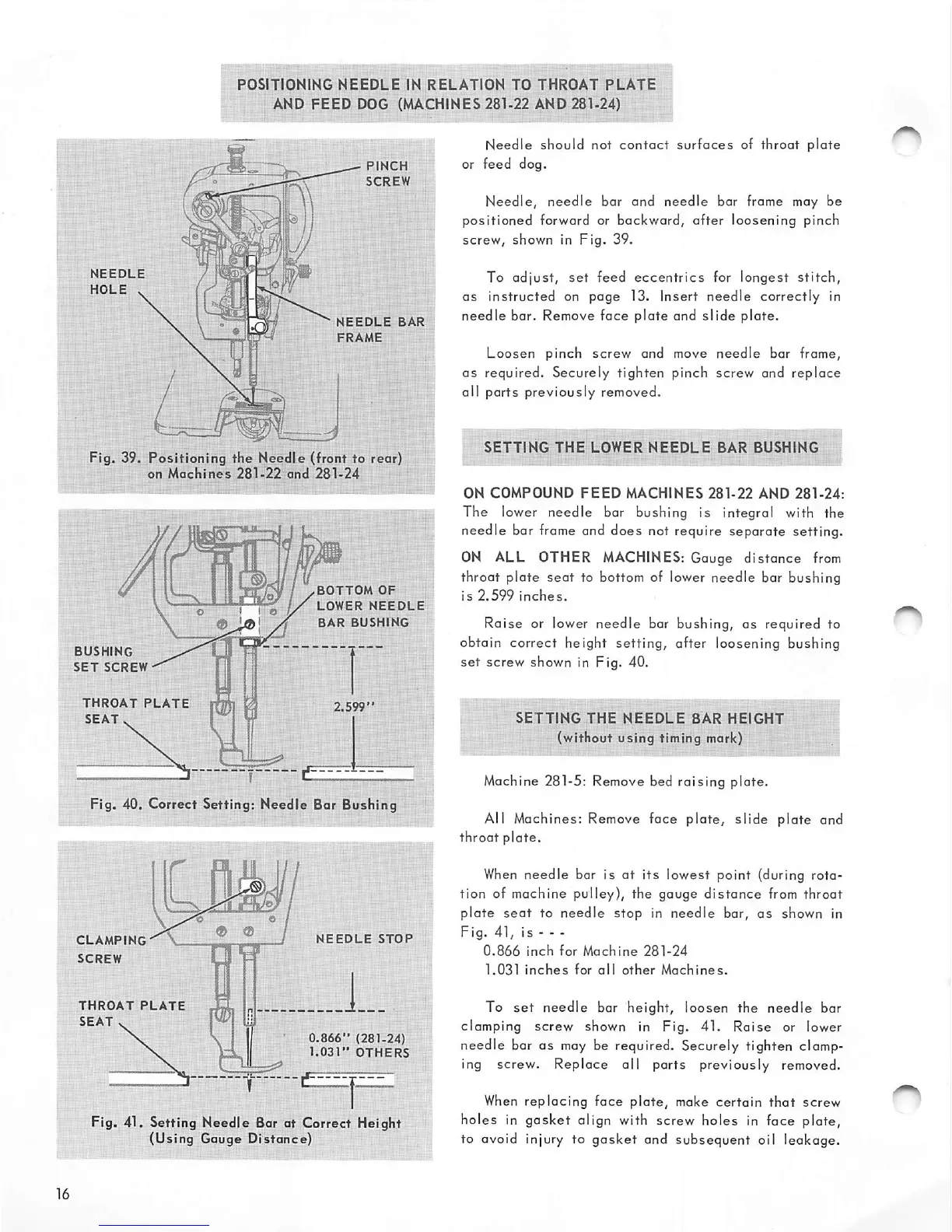

PINCH

SCREW

NEEDLE

BAR

FRAME

Fig.

39.

Positioning

the

Needle

(front to

rear)

on

Machines

281-22

and

281-24

THROAT

PLATE

SEATv

BOTTOM

OF

LOWER

NEEDLE

BAR

BUSHING

2.599"

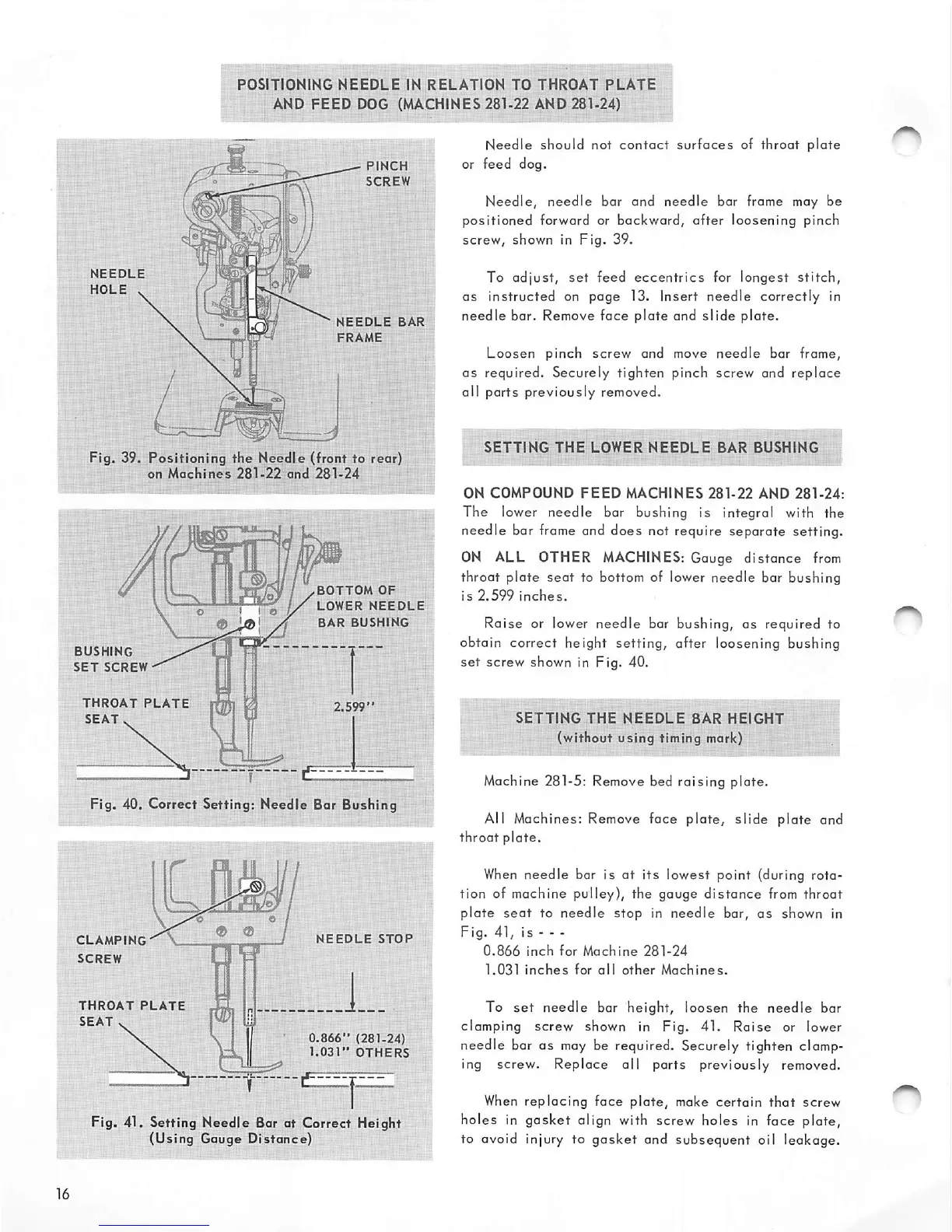

Fig. 40. Correct Setting: Needle Bar Bushing

THROAT

PLATE

SEAT

^

NEEDLE

STOP

J...

0.866"

(281-24)

1.031"

OTHERS

Fig. 41. Setting Needle Bar at Correct Height

(Using

Gauge

Distance)

Needle should not

contact

surfaces

of throat

plate

or feed dog.

Needle,

needle

bar

and

needle

bar frame may be

positioned forward or backward, after loosening pinch

screw,

shown in

Fig.

39.

To

adjust,

set

feed

eccentrics

for longest

stitch,

as

instructed

on

page

13. Insert

needle

correctly

in

needle

bar. Remove

face

plate

and

slide

plate.

Loosen

pinch

screw

and move

needle

bar frame,

as

required.

Securely

tighten

pinch

screw

and

replace

all parts previously removed.

SETTING

THE

LOWER

NEEDLE

BAR

BUSHING

ON

COMPOUND

FEED

MACHINES

281-22

AND

281-24:

The lower needle bar bushing is integral with the

needle bar frame and does not require separate setting.

ON

ALL OTHER

MACHINES:

Gauge distance

from

throat plate

seat

to bottom of lower

needle

bar bushing

is

2.599

inches.

Raise

or lower

needle

bar bushing, as required to

obtain

correct

height

setting,

after loosening bushing

set

screw

shown in

Fig.

40.

SETTING

THE

NEEDLE

BAR

HEIGHT

(without

using

timing mark)

Machine 281-5: Remove bed

raising

plate.

All Machines: Remove face plate, slide plate and

throat

plate.

When

needle

bar is

at

its

lowest point (during rota

tion of machine pulley), the gauge

distance

from throat

plate

seat

to

needle

stop

in

needle

bar,

as

shown in

Fig.

41, is - - -

0.866

inch

for

Machine

281-24

1.031

inches

for

all

other

Machines.

To

set

needle

bar

height,

loosen

the

needle

bar

clamping screw shown in Fig. 41. Raise or lower

needle bar as may be required. Securely tighten clamp

ing screw. Replace all parts previously removed.

When

replacing

face

plate,

make

certain

that

screw

holes in

gasket

align with screw holes in face plate,

to avoid injury to

gasket

and subsequent oil leakage.

Loading...

Loading...