SETTING

THE

TIMING-INDICATOR

PIN

(MACHINES 281-22 AND 281-24)

Set

needle

bar

at

correct

height,

as

instructed on

page

16.

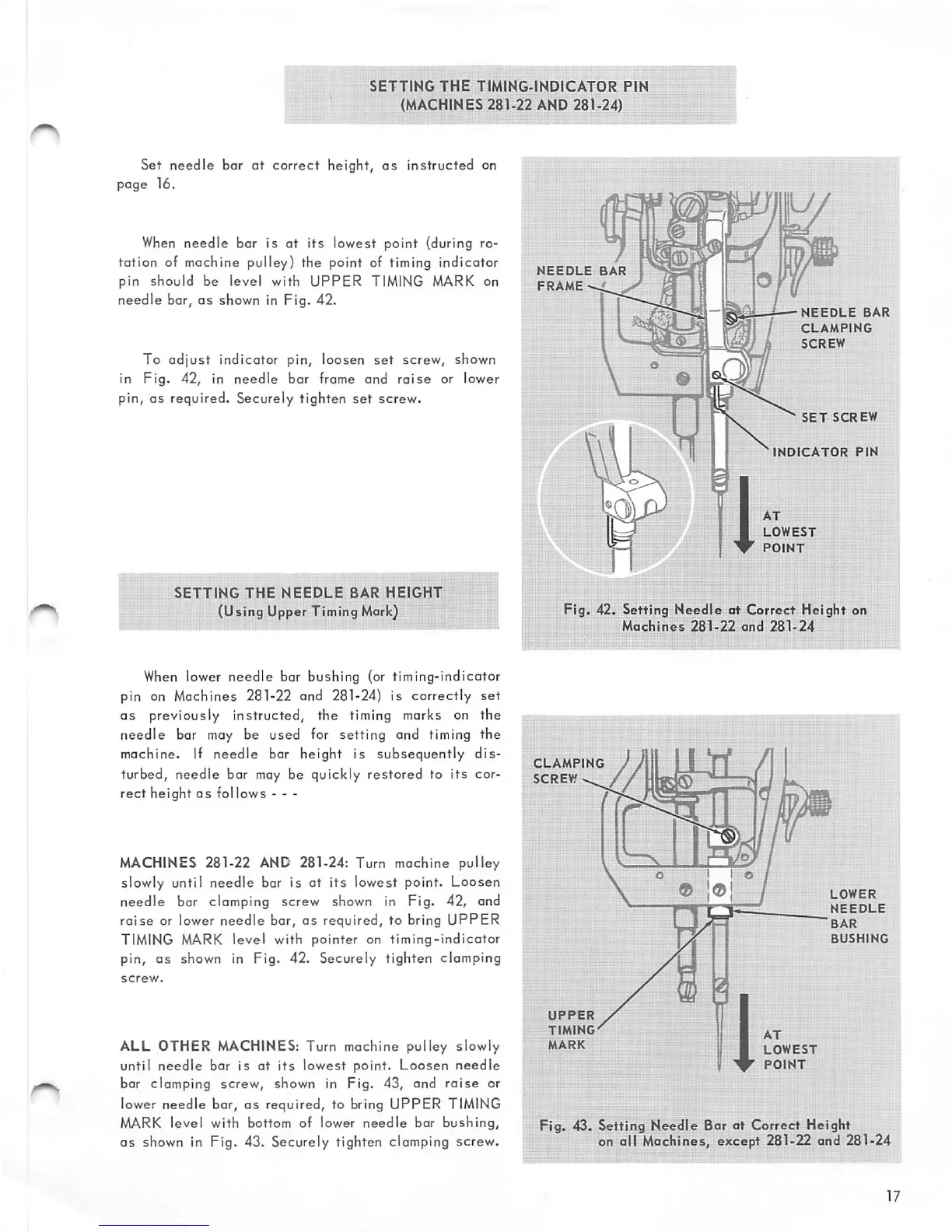

When

needle

bar is at its lowest point {during ro

tation

of machine pulley) the point of timing indicator

pin

should

be level with

UPPER

TIMING MARK on

needle

bar,

as

shown in Fig. 42.

To

adjust

indicator pin, loosen

set

screw, shown

in

Fig.

42, in

needle

bar

frame

and

raise

or lower

pin, as required. Securely tighten

set

screw.

SETTING

THE

NEEDLE

8AR

HEIGHT

(Using Upper Timing

Mark)

When lower

needle

bar

bushing

(or

timing-indicator

pin on Machines 281-22 and 281-24) is

correctly

set

as

previously instructed, the timing marks on the

needle bar may be used for setting and timing the

machine. If

needle

bar height is subsequently

dis

turbed, needle bar may be quickly

restored

to

its

cor

rect

height

as

follows

- - -

MACHINES 281-22 AND 281-24: Turn machine pulley

slowly until

needle

bar is at

its

lowest point.

Loosen

needle

bar clomping screw shown in Fig. 42, and

raise

or lower

needle

bar,

as

required, to bring

UPPER

TIMING MARK

level

with

pointer

on

timing-indicator

pin, as shown in Fig. 42. Securely tighten clamping

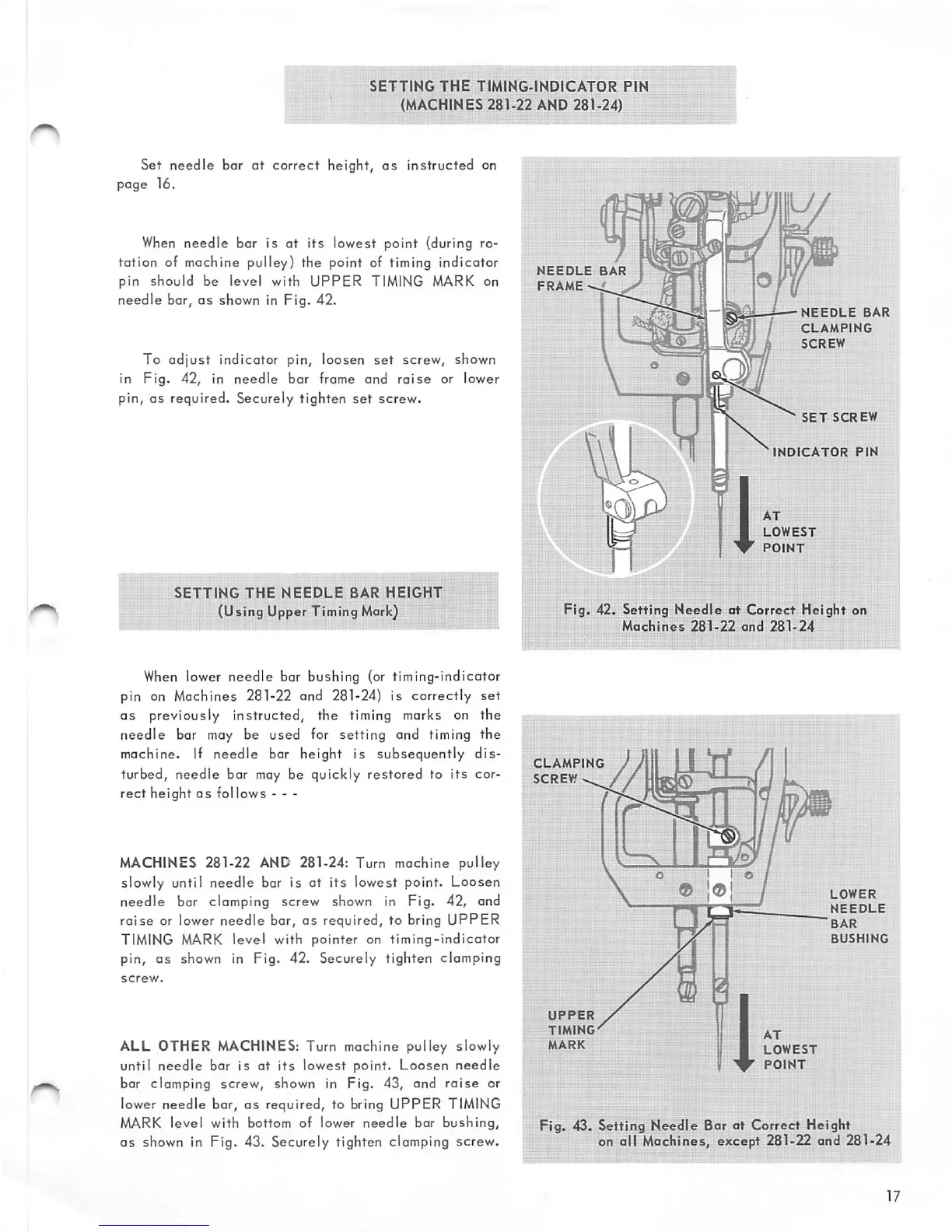

ALL OTHER

MACHINES:

Turn machine pulley slowly

until

needle

bar is at

its

lowest

point.

Loosen

needle

bar clamping screw, shown in Fig. 43, and

raise

or

lower needle bar,

as

required, to bring UPPER TIMING

MARK

level

with bottom of lower

needle

bar

bushing,

as shown in Fig. 43. Securely tighten clamping screw.

NEEDLE

BAR

FRAME--.'

^

NEEDLE

BAR

CLAMPING

SCREW

SET

SCREW

INDICATOR

PIN

AT

LOWEST

POINT

Fig. 42. Setting

Needle

at Correct Height on

Machines

281-22

and

281-24

CLAMPING

SCREW

^

UPPER

TIMING'

MARK

® 1®

AT

LOWEST

POINT

LOWER

NEEDLE

BAR

BUSHING

Fig.

43.

Setting

Needle

Bar at

Correct

Height

on all Machines, except 281-22 and 281-24

Loading...

Loading...