LUBRICATION

Before

starting

machine,

the

oil

reservoir

must be

filled to

HIGH

MARK

shown in Fig. 2

Use

SINGER

OIL

"TYPE

A"

or

"TYPE

C".

Use

"TYPE

C"

OIL when an oil is

desired

which will

produce a minimum

of

stain

on

fabrics

even

after

a

long period of storage.

Do not use

additives

in sewing machine oil,

as

they

may

cause

a

reduction

in normal oil flow

that

can

result

in damage to machine.

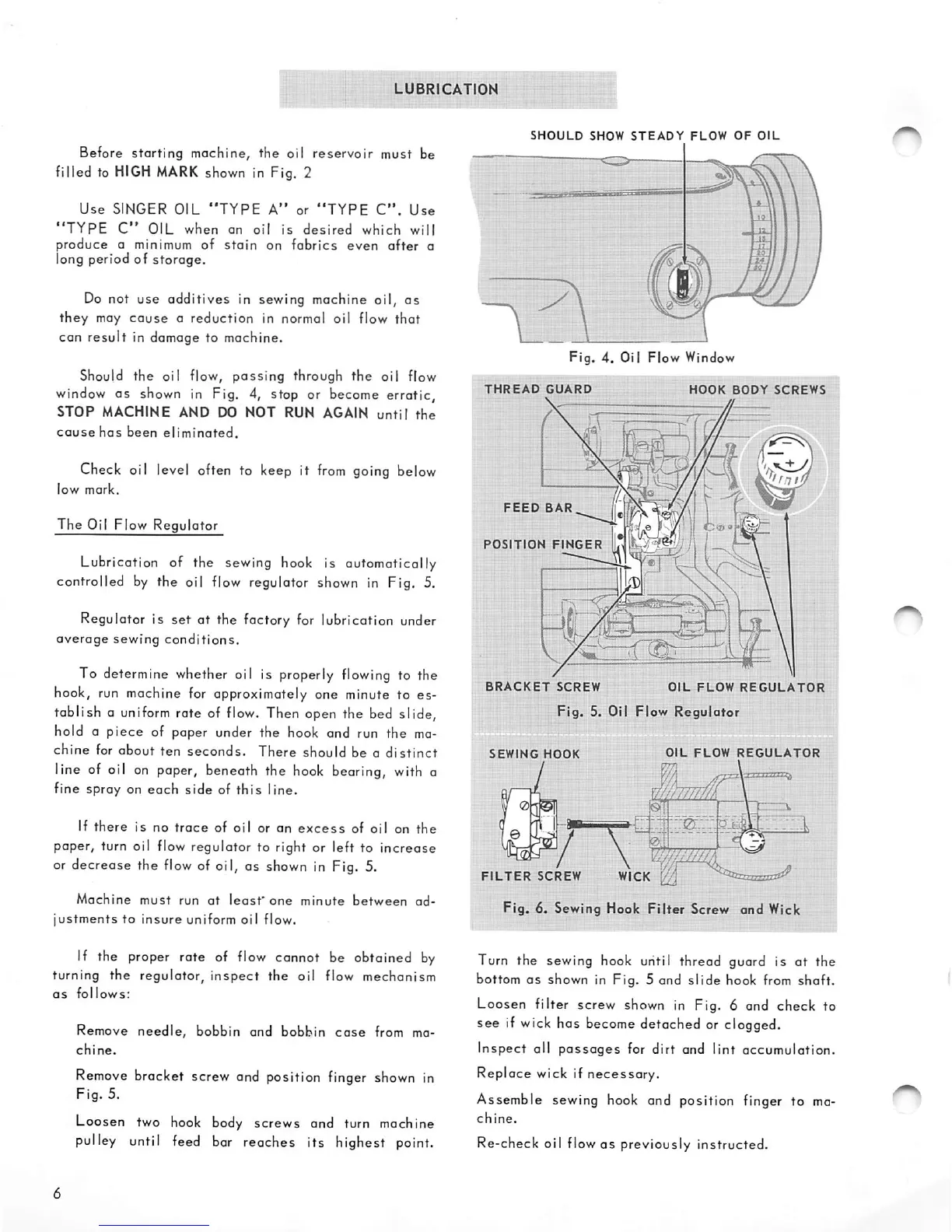

Should

the

oil flow,

passing

through

the

oil flow

window

as

shown

in Fig. 4, stop or

become

erratic,

STOP MACHINE AND DO NOT RUN AGAIN

until

the

cause

has

been

eliminated.

Check oil level often to keep it

from

going below

low

mark.

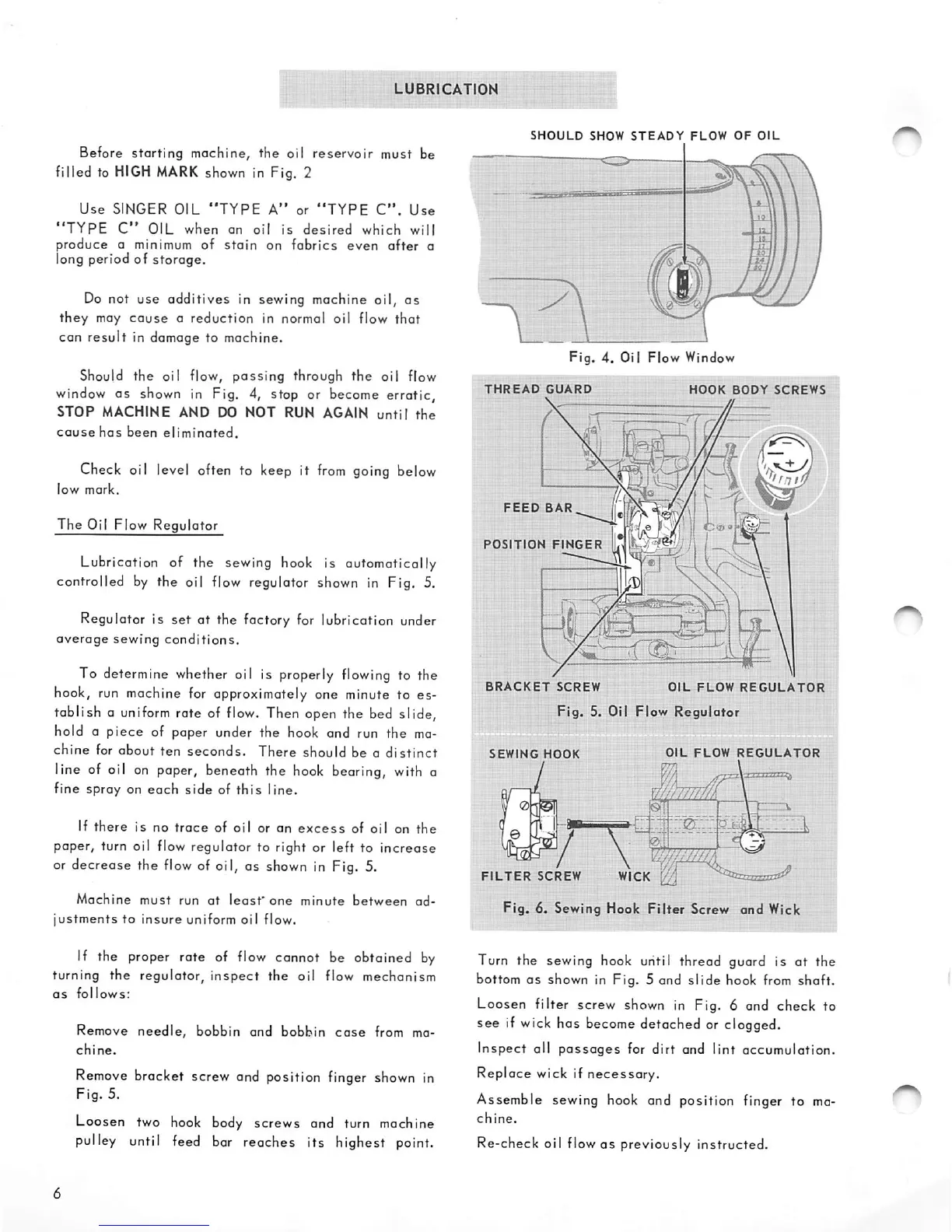

The Oil Flow Regulator

Lubrication of the sewing hook is automatically

controlled by the oil flow regulator shown in Fig. 5.

Regulator is set at the factory for lubrication under

average

sewing

conditions.

To determine whether oil is properly

flowing

to the

hook,

run

machine for approximately one minute to es

tablish a

uniform

rate of

flow.

Then open the bed slide,

hold 0

piece

of paper under the hook and run the ma

chine for about ten

seconds.

There should be a

distinct

Iine of oil on paper, beneath the

hook

bearing, with a

fine spray on

each

side

of

this

line.

If

there

is no

trace

of oil or an

excess

of oil on

the

paper, turn oil

flow

regulator to right or left to increase

or decrease the

flow

of oil, as shown in Fig. 5.

Machine

must

run

at

least'

one

minute

between

ad

justments

to

insure

uniform oil flow.

If the proper rote of flow cannot be obtained by

turning the regulator, inspect the oil flow mechanism

as

follows:

Remove

needle,

bobbin and bobbin

case

from ma

chine.

Remove

bracket screw and position finger

shown

in

Fig.

5.

Loosen two

hook

body screws and turn machine

pulley until feed bar reaches its highest point.

SHOULD

SHOW

STEADY

FLOW

OF

OIL

Fig.

4. Oil Flow Window

THREAD

GUARD

HOOK

BODY

SCREWS

FEED

BAR

POSIT,OH

BRACKET

SCREW

OIL

FLOW

REGULATOR

Fig.

5. Oil Flow

Regulator

SEWING

HOOK

OIL

FLOW

REGULATOR

a

U-

FILTER

SCREW

WICK

Fig. 6. Sewing Hook

Filter

Screw and Wick

Turn the sewing hook until thread guard is at the

bottom as shown in Fig. 5 and slide hook

from

shaft.

Loosen filter screw shown in Fig. 6 and check to

see if wick has become detached or clogged.

Inspect all

passages

for dirt and lint accumulation.

Reploce wick if necessary.

Assemble sewing

hook

and position finger to

ma

chine.

Re-check oil flow

as

previously instructed.

Loading...

Loading...