SETTING

THE

FEED

DOG HEIGHT

(Continued)

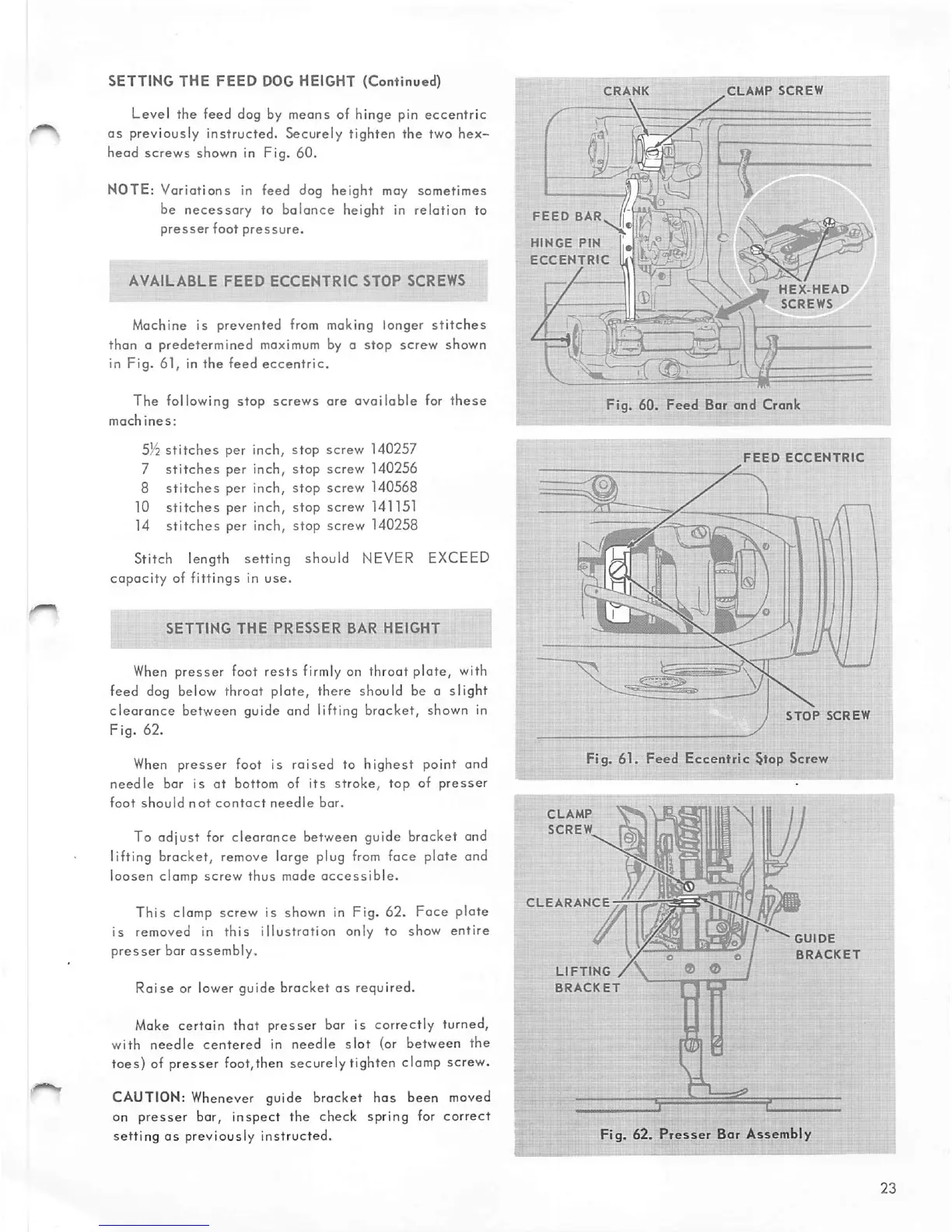

Level the feed dog by means of hinge pin

eccentric

as

previously instructed. Securely tighten the two

hex-

head screws shown in Fig. 60.

NOTE: Variations in feed dog height may sometimes

be

necessary

to

balance

height in relation to

presser

foot

pressure.

AVAILABLE

FEED

ECCENTRIC

STOP

SCREWS

Machine is prevented from making longer

stitches

than a predetermined maximum by a stop screw shown

in

Fig.

61, in

the

feed

eccentric.

The following stop

screws

are

available

for

these

machines:

SYi

stitches

per inch, stop screw 140257

7

stitches

per inch, stop screw 140256

8

stitches

per inch, stop screw 140568

10

stitches

per inch, stop screw 141151

14

stitches

per inch, stop screw 140258

Stitch length setting should NEVER EXCEED

capacity

of

fittings

in

use.

SETTING

THE

PRESSER

BAR

HEIGHT

i

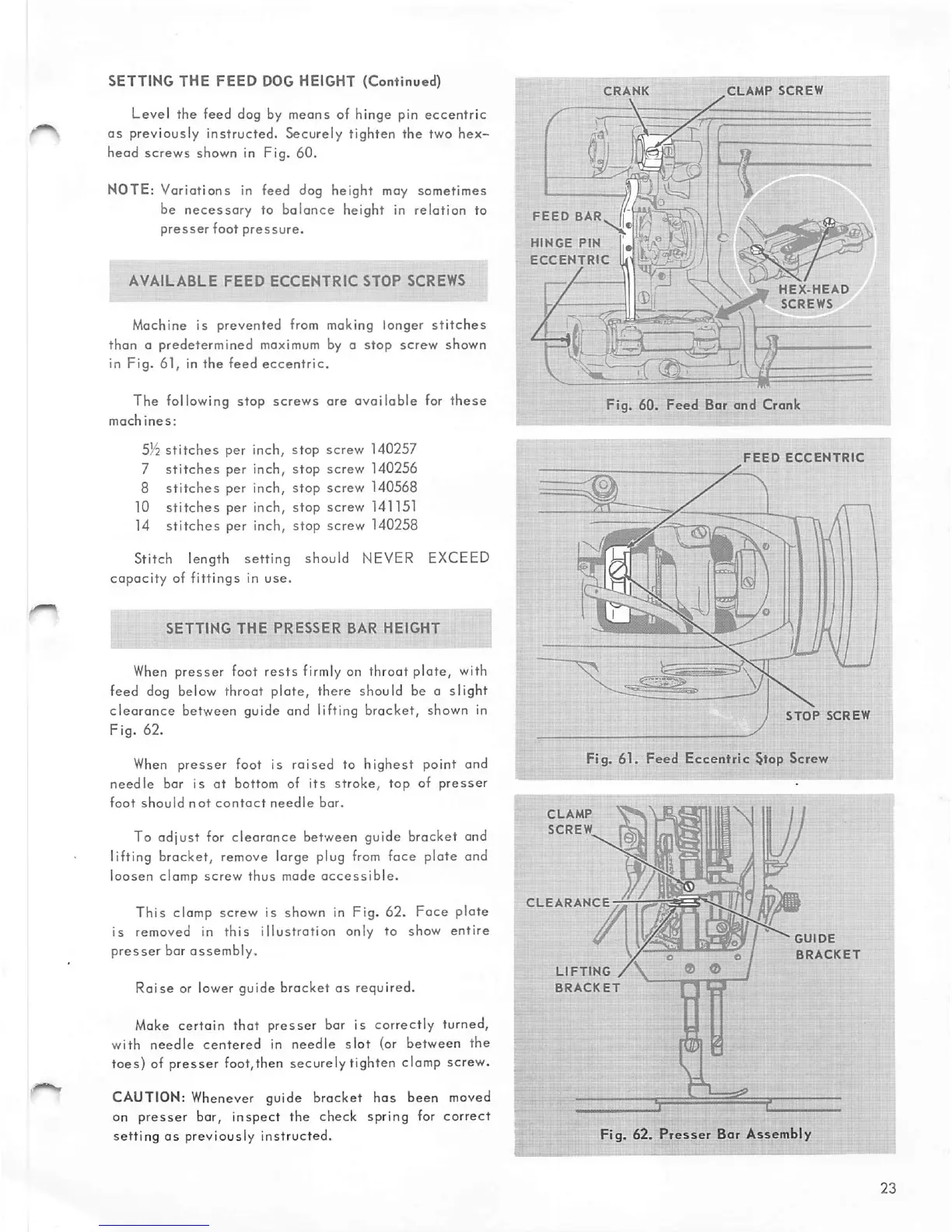

When

presser foot

rests

firmly on throat plate, with

feed dog below throat plate, there should be a slight

clearance

between guide and lifting bracket, shown in

Fig. 62.

When

presser foot is raised to highest point and

needle

bor is at bottom of

its

stroke,

top

of

presser

foot

should

not

contact

needle

bar.

To adjust for clearance between guide bracket and

lifting bracket, remove large plug

from

face plate and

loosen clamp screw thus made

accessible.

This

clamp screw is shown in Fig. 62.

Foce

plate

is

removed in

this

illustration

only to show

entire

presser

bar

assembly.

Raise

or lower guide bracket

as

required.

Make

certain that presser bar is correctly turned,

with

needle

centered

in

needle

slot

(or

between

the

toes) of presser foot,then securely tighten clamp screw.

CAUTION: Whenever guide bracket has been moved

on

presser

bar,

inspect

the check spring for

correct

setting

as

previously instructed.

CRANK

FEED

BAR

HINGE

PIN

ECCENTRIC

-

CLAMP

SCREW

HEX-HEAD

SCREWS

Fig.

60.

Feed

Bar

and

Crank

FEED

ECCENTRIC

Fig. 61.

Feed

Eccentric

§top Screw

CLAMP

SCREW_

CLEARANCE

LIFTING

/

BRACKET

o e

GUIDE

BRACKET

Fig. 62.

Presser

Bar Assembly

Loading...

Loading...