SETTING

THE

CHECK

SPRING

HEIGHT

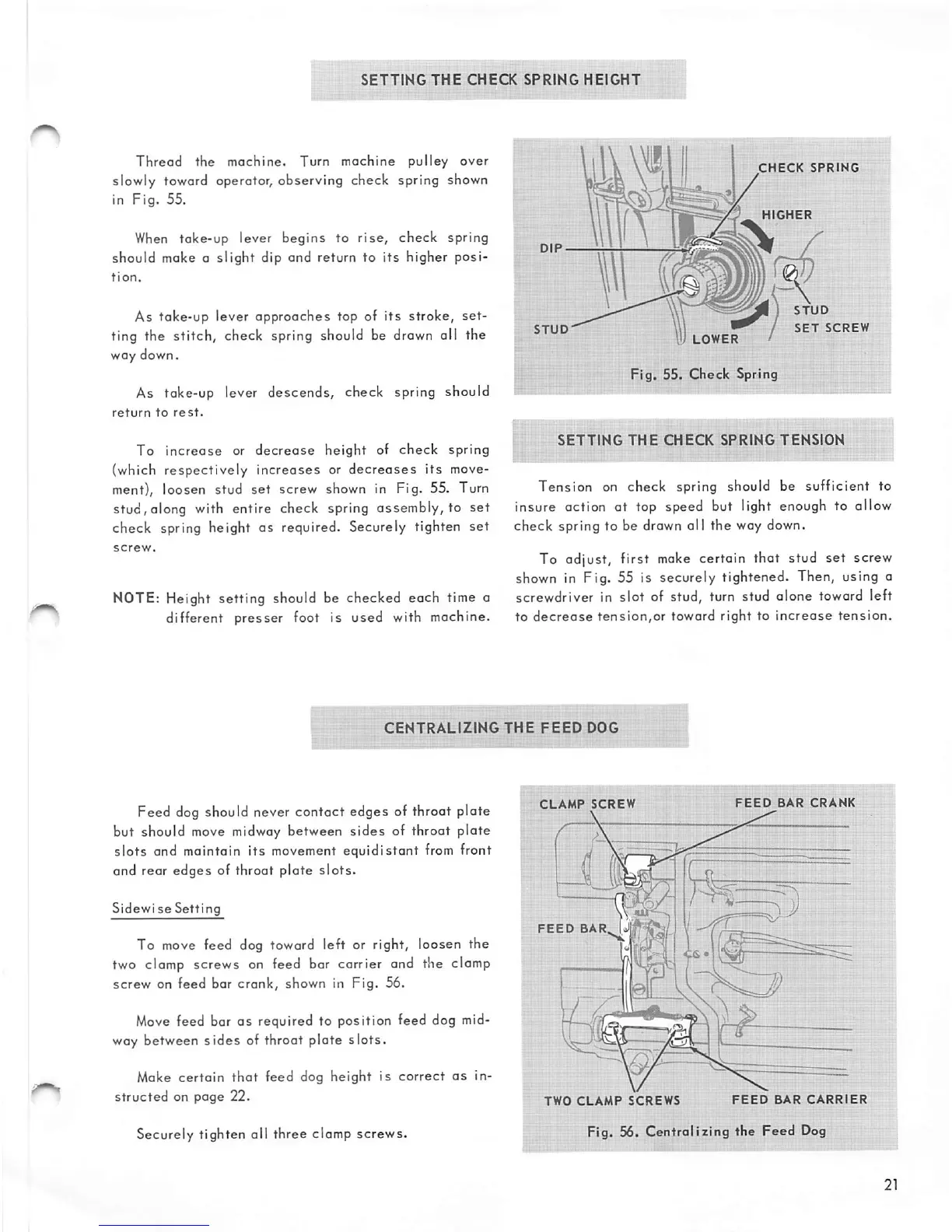

Thread

the mochine. Turn machine pulley

over

slowly toward operator, observing check spring shown

in

Fig.

55.

When

take-up lever begins to

rise,

check spring

should moke a

slight

dip and return to

its

higher posi-

As toke-up lever

approaches

top of

its

stroke,

set

ting the stitch, check spring should be drawn all the

way down.

As take-up lever descends, check spring should

return

to

rest.

To

increase

or

decrease

height of

check

spring

(which

respectively

increases

or

decreases

its

move

ment), loosen stud

set

screw shown in Fig. 55. Turn

stud, along with entire check spring ossembly, to set

check spring height as required. Securely tighten set

NOTE: Height setting should be checked each time a

different presser foot is used with machine.

ir

LOWER

CHECK

SPRING

HIGHER

\

STUD

SET

SCREW

1.

Fig.

55.

Check

Spring

SETTING

THE

CHECK

SPRING

TENSIO

Tension on check spring should be sufficient to

insure action at top speed but light enough to allow

check spring to be drawn all

the

way down.

To adjust, first

make

certain that stud set screw

shown in Fig. 55 is securely tightened. Then, using a

screwdriver in

slot

of stud, turn stud alone toward left

to

decrease

tension,or

toward right to

increase

tension.

CENTRALIZING

THE

FEED

D0(

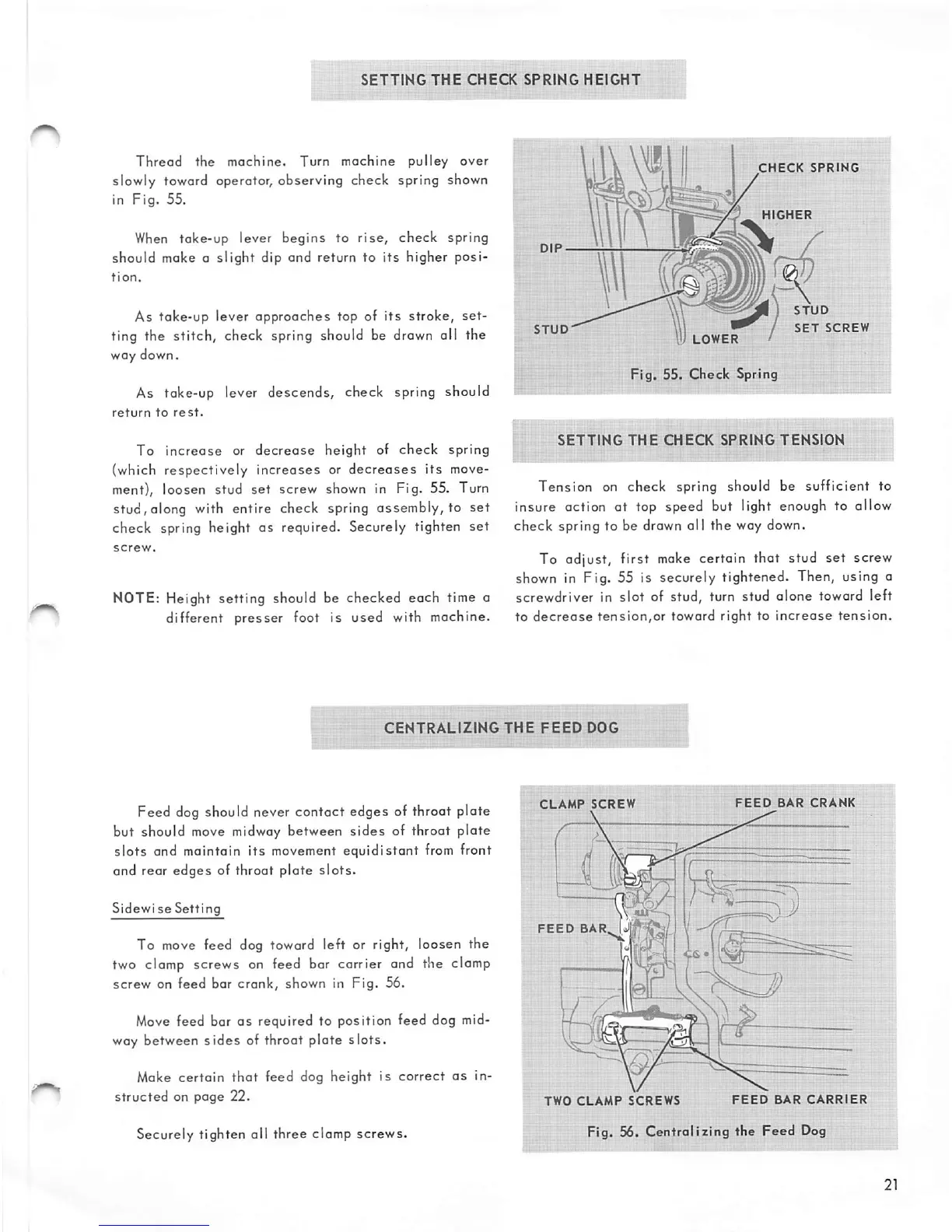

Feed dog should never contact edges of throat plate

but should move midway between sides of throat plate

slots

and maintain

its

movement

equidistant

from front

and rear

edges

of throat plate

slots.

Sidewi

se

Setting

To move feed dog toward left or right, loosen the

two clamp screws on feed bar carrier and the clamp

screw

on feed bar

crank,

shown in

Fig.

56.

Move

feed bar as required to position feed dog mid

way between

sides

of throat plate

slots.

Make

certain

that

feed dog

height

is

correct

as

in

structed

on

page

22.

Securely tighten all three clamp screws.

CLAMP

SCREW

FEED

BAR

CRANK

FEED

BAR

Am

TWO

CLAMP

SCREWS

FEED

BAR

CARRIER

Fig. 56. Centralizing the Feed Dog

Loading...

Loading...