SiMUaA

®

Sew

Reach

P10

Introduction

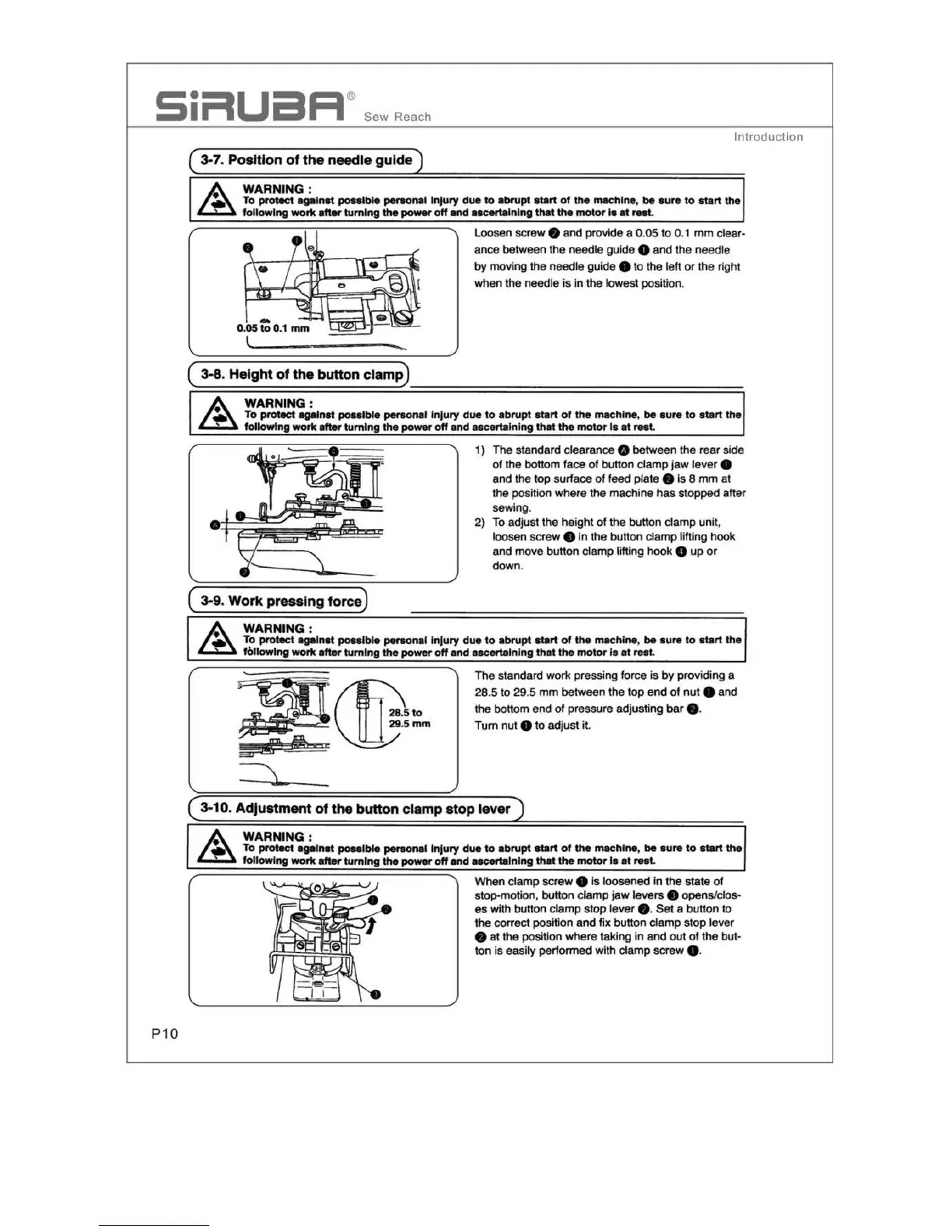

( 3-7. PosHlon

of

the needle guide)

Loosen screw e and provide a 0.

05

to 0.1

mm

clear-

an

ce

between the needle guide e

and

the needle

by moving the

need

le guide e to the left

or

the right

when the needle

is

in the lowest position.

(

3-8

. Height of

the

button clamp)

•

WARNING :

To

proe.ct

against

poulble

personal I

njury

due

to

a

brupt

s

ta

rt

ol

the

machine,

be

sure

to

s

tart

the

following

work

after

turning

the

power

off

and

ascertaining

that

the

motor

Is

at

rest.

1) T

he

standard clearan

ce

e

be

tw

een the rear si

de

of the

bo

ttom

f

ace

of button clamp

jaw

lever 8

and the t

op

surface

of

feed plate •

is

8 mm

at

the position where the machine has stopped after

sewing.

2)

To adjust the

he

i

ght

of

the button clamp unit,

loosen screw

•

in

t

he

bu

tt

on

clamp lifting hook

and move button clamp lifting hook

8 up or

do

wn.

( 3-9. Work pressing force)

WARNING

:

To pro18ct against

poNlble

per90nal I

njury

due

to

abrupt

start

of

the

mach

i

ne

,

be

sure

to

start

th

e

followlng work

after

turning

the

power

off

and

ascertaining

that

the

motor

Is

at

rest.

~®-

510

~

29

.

5mm

l1'!i

& e

ar=

~

The

standard work pressing for

ce

is by providing a

28

.5

to

29

.5

mm

between the

to

p

en

d

of

nu

t e and

the bottom end

of

pressure a

dj

usting

bar

• ·

Turn nut

e

to

adju

st

it.

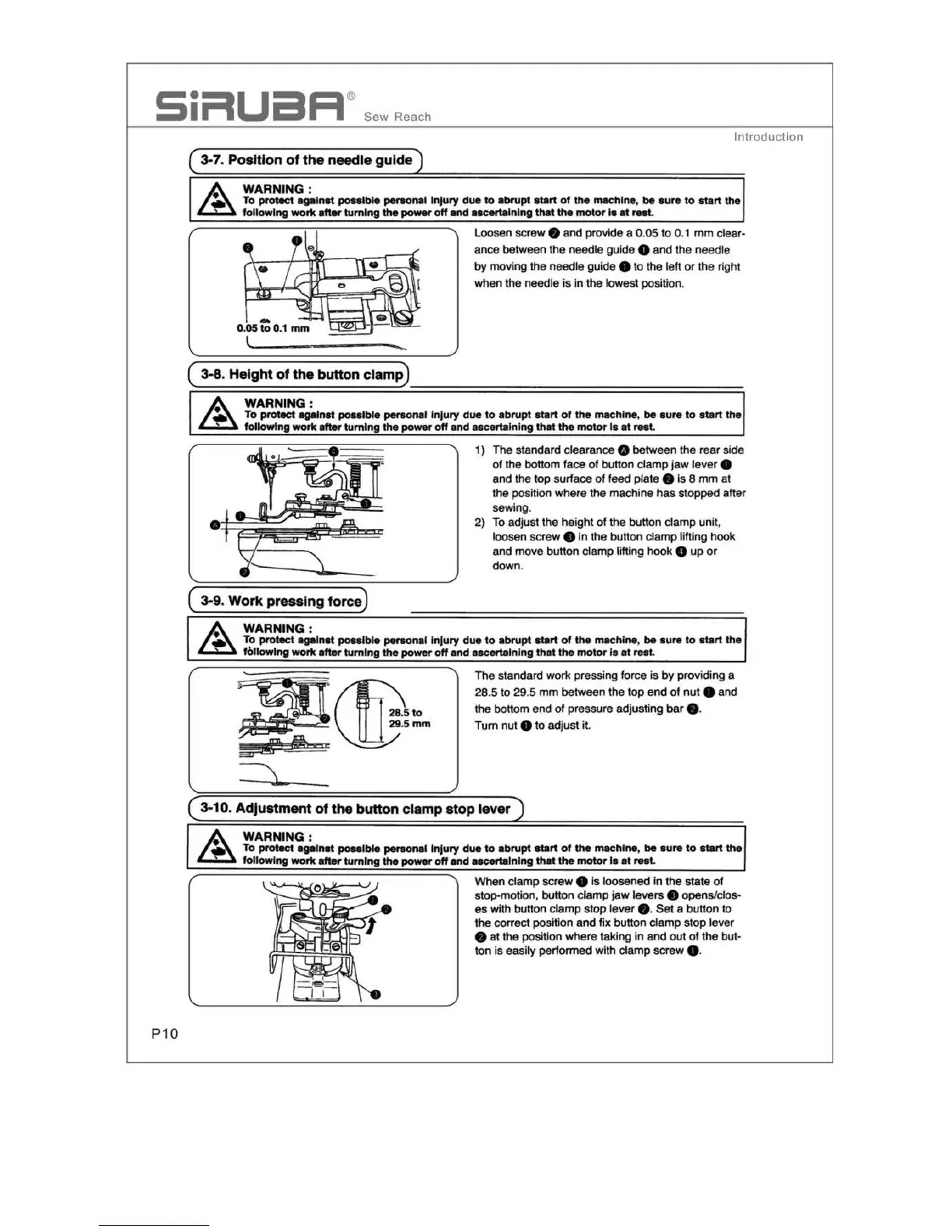

( 3-10. Adjustment

of

the button clamp stop lever )

WARNING:

To

proe.ct

against

poNlble

penona1

Injury

due

to

a

brupt

start

of

the

machine

,

be

su

re

to

start

the

following

work

after

turning

the

power

off

and

asc«talnlng

that

the

motor

fa

at

mt

.

When

clamp

scre

w e

is

loosen

ed

in

the state

of

stop-motion, button clamp

ja

w levers e opens/clos-

es

with button cl

amp

stop

lev

er e.

Set

a

bu

tt

on

to

the correct

posi

tion and

fix

button clamp

sto

p l

ever

e at t

he

posi11on

where taking

in

an

d

out

of

the

but-

ton

is

easily performed with clamp screw • ·

Loading...

Loading...