SiMUaA

®

Sew

Reach

P14

Introduction

( 3-18. Knot-tying mechanisms)

WARNING :

To

protec

t

against

po

H

lble

pareonal

Injury

due

to

abrupt

start

of

the machi

ne

,

be

aura

to

start the

following

work

after

turning

the

po-

off

and aacertalnlng

that

the

mo

tor

la

at

rest.

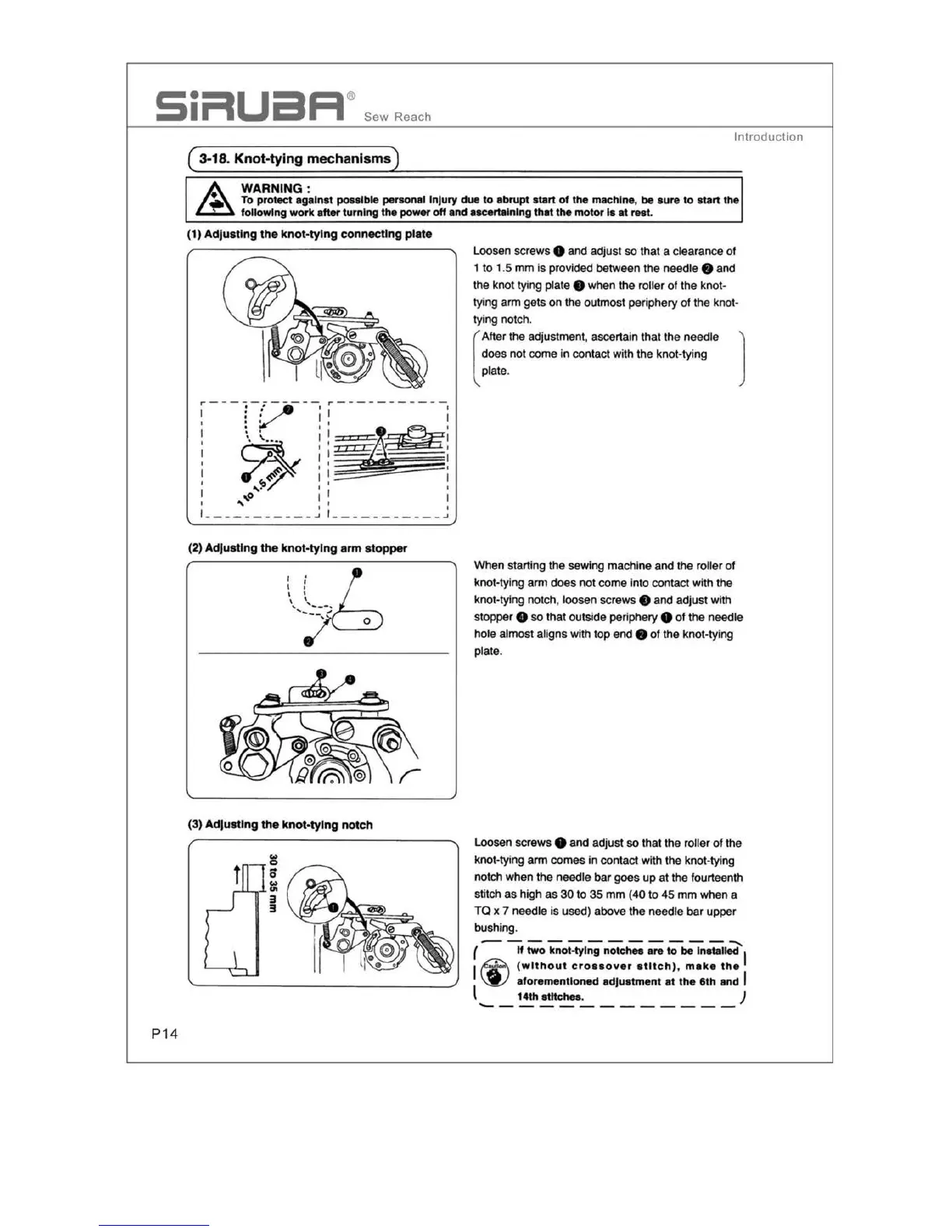

(1) Adjusting

the

knot-tying connecting plate

,----

,-y

--

1 :

,'

I : I

I

' '

~

~~

,o

"

1

__________

_

I I

I

___________

_,

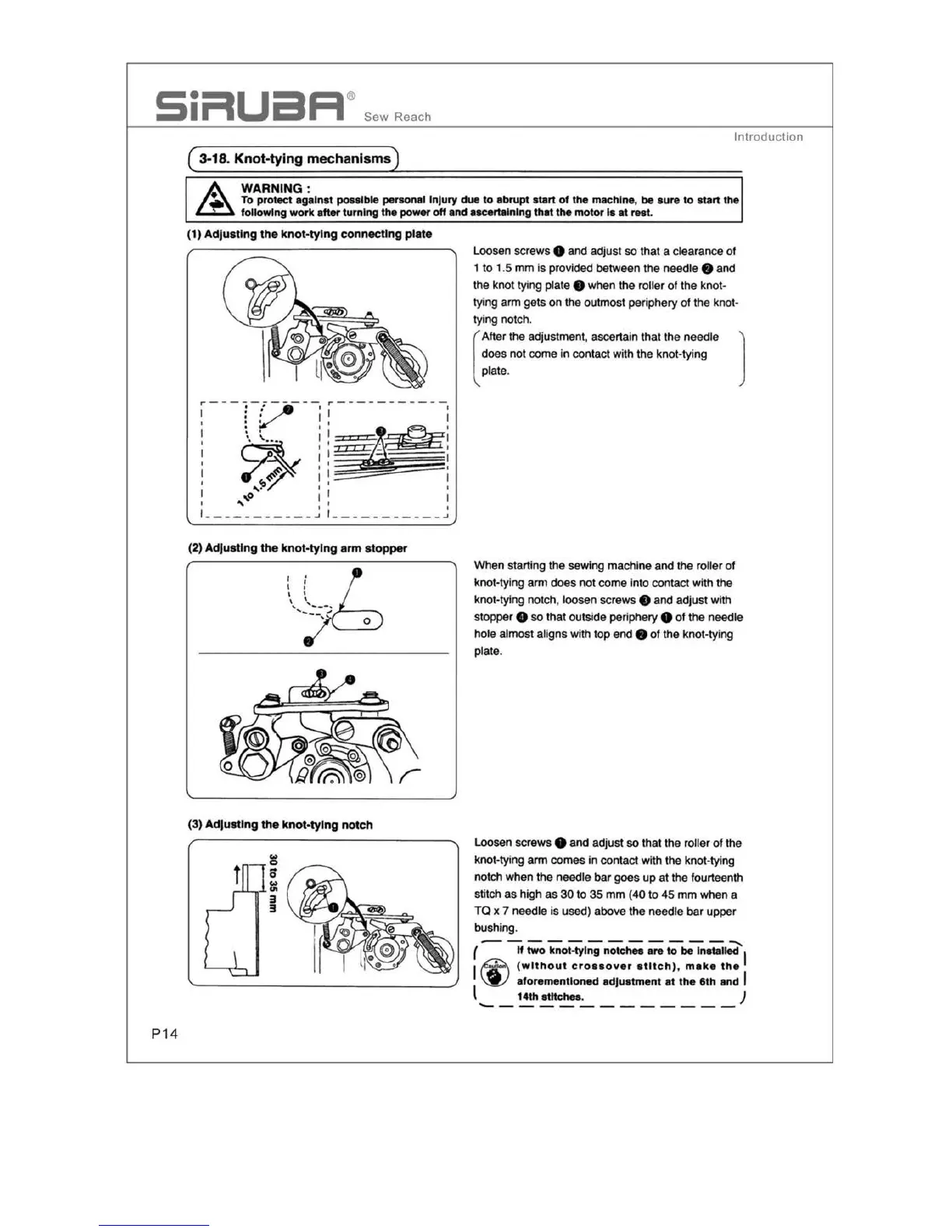

(2) Adjusting

the

knot-tyi

ng

arm stopper

·~

' :

I '

\.

\..,.

__

,

'---

..

.,,

0

(3) Adjusting

the

knot-tying

notch

Loosen screws 8

and

adjust so that a clearance of

1 to 1.5

mm

is

provided between the needle 8 and

the knot tying plate

• when the roller

of

the knot-

tying arm gets

on

the outmost

per

iphery

of

the knot-

tying notch.

(

After the adjustment, ascertain that the needle

does

not

come

in

contact with the knot-tying

plate.

]

When starting

the

sewing machine and t

he

roller of

knot-tying arm

does

not

come

i

nt

o contact with

th

e

kn

ot-tying notch, loosen screws • and adjust with

stopper

8 so

tha

t o

ut

side

per

ip

hery 8

of

t

he

needle

hole almost aligns with top

end

•

of

the

knot

-tying

plate.

Loosen screws

e

and

adjust so that the roller

of

the

knot-tying arm

comes

in

cont

act

with

the

knot-ty

in

g

notch when the needle

bar

goes

up

at

the fourteenth

stitch

as

high

as

30

to

35

mm

(40

to

45

mm

wh

en

a

TO

x 7 needle

is

used) above the needle

bar

upper

bushing.

-----

-------

-

(

If

two

knot-tyi

ng

notci-

are

to

be

In

sta

lled I

I ~.•

(without

c

roa

aove

r

stitc

h)

,

make

the

~

aforementioned

adJu

at

ment

at

the

6th

and

I

l

14

th

atltchN.

/

..._,

___

________ _

Loading...

Loading...