SiMUaA

®

Sew

Reach

Introduction

( 3-11.

Timing

of

thread

tension

release)

•

Phenomenon

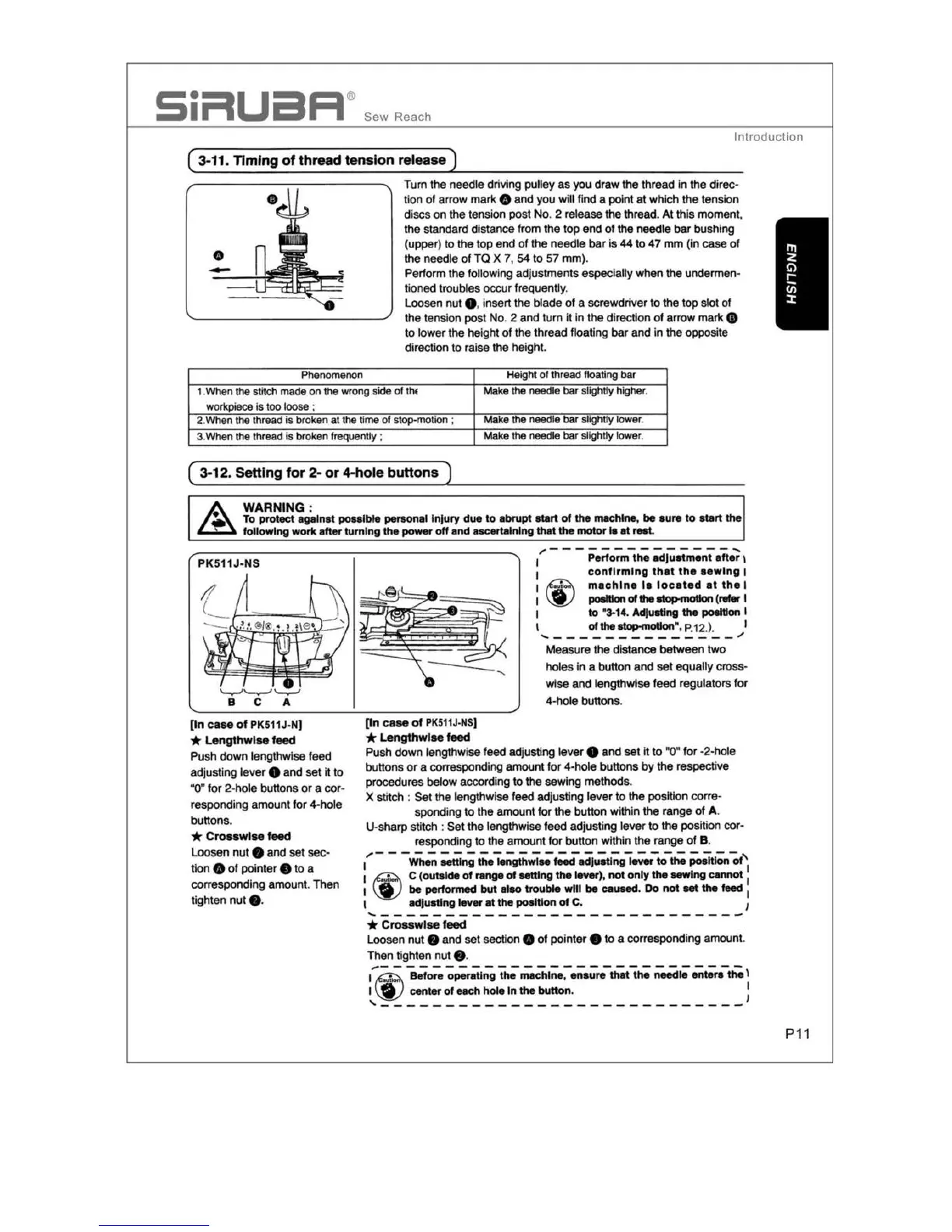

Tum

the needle driving pull

ey

as

you draw

the

thread in

the

direc-

tion of arrow

mark

e

and

you

will find a point

at

wh

ich

th

e tension

discs

on

the

tension post

No

. 2

re

lease the thread. At this

moment

,

the standard distance from

the top

e

nd

of the needle bar bushing

(upper) to

the

top

end

of

the

needle

bar

is

44

to 47

mm

(in

case

of

the needle

of

TO

X

7,

54

to

57

mm

).

Perform

the

following adjustments especially when the undermen-

tioned troubles

occu

r

fr

equently

.

Loosen nut

e. insert the

blade

of

a

sc

rewdriver to

the top

slot

of

the

tension post No. 2

and

tum

it

in

the

direction

of

arrow mark •

to lower

the

height

of

the thread floating

bar

and

in

the

opposite

direction to rai

se

the height.

Height

of

thread

floating

bar

1.

When

the

stitch

made

on

t

he

wrong

side

of

thl

Make the

needle

bar

slightly h

igher

.

worl<piece

Is

too

loose

:

2.When

the

thread

is

broken

at

the

lime

of

stop-mo

t

ion

;

Mak

e

the

needle

bar

slightly IOwer.

3.When

the

thread

is

broken

frequently :

Make

the

needle

bar

slightly

lower

.

( 3-12. Setting

for

2-

or

4-hole

buttons

)

WARNING :

To

protect against possible personal lnfury

due

to

abrupt start

of

the

machine,

be

sure

to

start

the

followlng

wort<

after

turning

the power

off

and

ncertalnlng

that

the

motOI'

le

at reel.

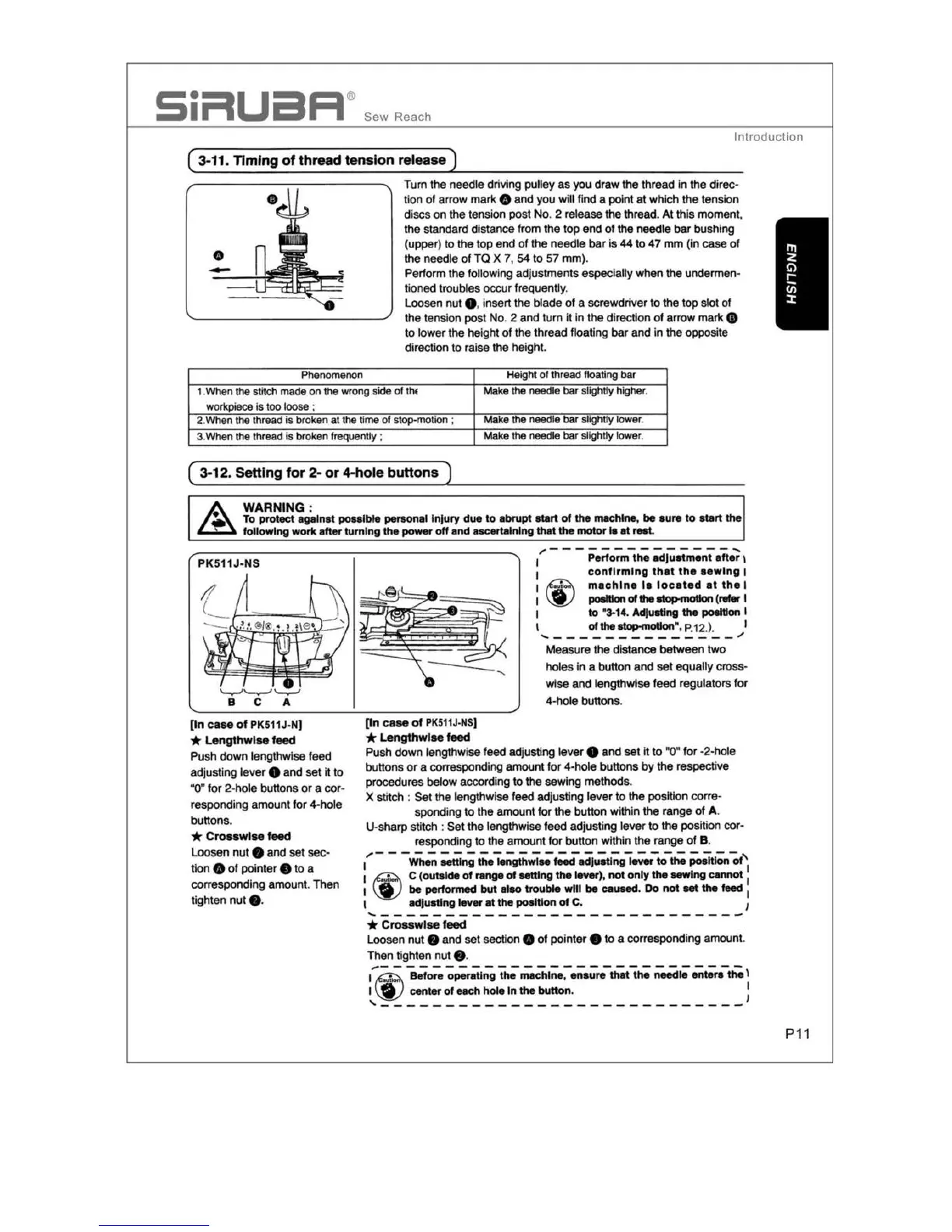

PK511J-NS

[In

C8M

of

PK511

J•NJ

* Lengthwise

feed

Pu

sh

down

lengthwise feed

adjusting

lever

•

and

set

it

to

·

o•

for

2-hole

bvttons

or

a cor-

responding amount

for

4-hole

buttons.

* Crosswise feed

L

oosen

nu

t e

and

set

sec-

tion

8

of

pointer e to a

correspo

nding amoun

t.

Then

tighten

nut

• ·

[In case

of

PK511J-NS)

* Lengthwise feed

,,,.--

------------

.....

1

Perform

the

adJuatment after \

1

confirming

that

the

sewing

I

I

~

machin

e

II

located

at

tha

I

I

\!I)

poallonofhaop,motiol,(,.,

I

I

to

"3-14. Adjusting

the

polltlon I

I

of

thutop•mollon", P

.12.l.

I

, ______________

,,,,

Measure

the

d

ista

nce

between

two

holes in a button

and

set

equa

lly cross•

wise

and

length

wise

feed regulators for

4-hole buttons.

Push

down

lengthwise feed adjusting

lever

e

and

set

it

to

•o• for -2-hole

butto

ns

or

a correspondi

ng

amount

for

4

-ho

le

buttons

by

the respective

procedures below according to

the

sewing

methods

.

X stitch :

Set

the lengthwise

feed

adjusting l

ev

er

to

the

position corre-

spondi

ng

to the amount

for

the

button with

in

the

range

of

A.

U

-s

harp

stitch :

Se

t

the

lengthwise

feed

adjusti

ng

lever

to

the

position

co

r-

responding

to

the

amount for button within

the

range

of

B.

~----------------------------~

I When setting

the

tengthwfM feed adjusting leYef

to

the posfflon

of

I

1

~

c (outside

of

range

of

setting the leYef),

not

only

the

NWlng

cannot

1

I

\!I)

be

performed

but

allO troub6e

wtll

be

caueed.

Do

not

Nt

the

feed I

I adJuetlng lever

at

the

position

of

C.

I

, ______________________ ___

__

_

* Crosswise feed

Loosen

nut

e a

nd

set

section e

of

pointer e to a

co

rrespond

in

g amount.

The

n tighten

nut

• ·

I~ Before operating

the

machine, ensure

th

at

the needle entere

the\

I

~

center

of

each

hole In

the

button. I

'----------------------------

'

P11

Loading...

Loading...