Page 97

EN

15. Operational and pump faults

15.1 KFGS operational malfunctions

15.1.1 General

The operator/operating personnel must

reservoir at regular intervals. The control in-

tervals depend on the amount of lubricant re-

quired and the pump's run time. The operator/

operating personnel must therefore determine

conditions of usage.

If the reservoir has been emptied, the entire

Chapter 6, Assembly).

KFGS

stops the normal operational sequence and the

fault that has occurred is saved and displayed.

The cause of the fault can be read on the dis-

though it requires system monitoring.

15.1.2 Display faults

Start the display mode with one of the

two keys

Press the

key until you reach the

-

edged and deleted using the

key. In timer

operation, this can also be performed using an

external pushbutton, if installed.

Warning!

Determine and remedy the cause of

The user is liable for damages resulting

from operating the machine without

lubrication.

The time during which the control unit

and pump unit have been operated

without lubrication is stored as fault

hours Fh in the EEPROM and cannot be

deleted.

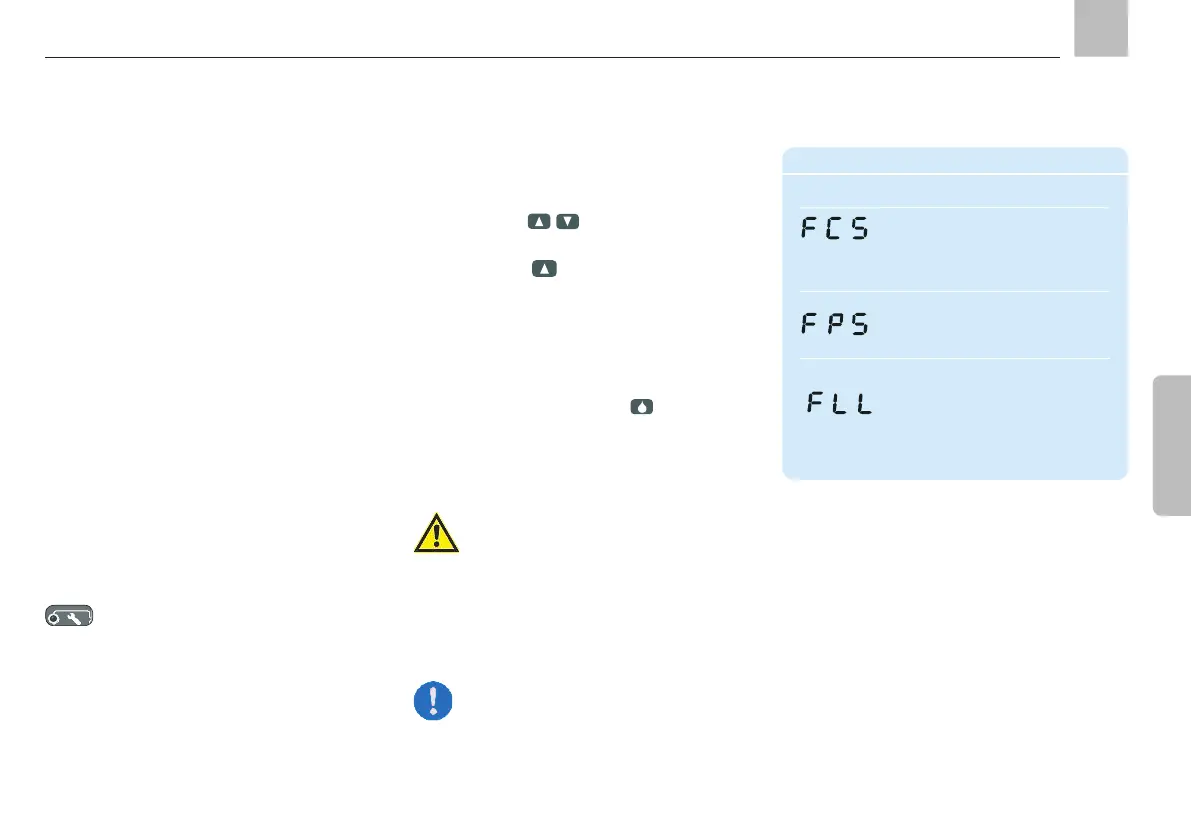

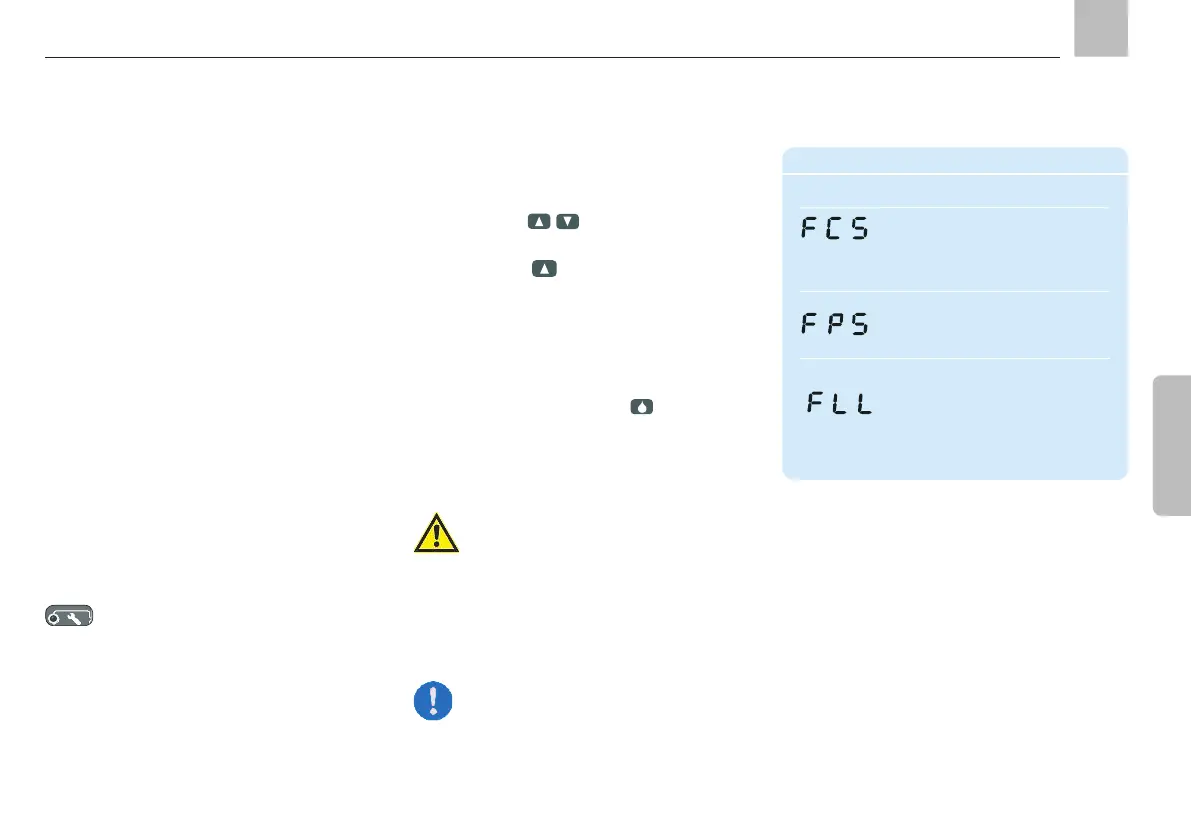

Fault notification

Display Meaning

Fault Cycle Switch:

No signal from piston detector

during pump cycle

(see Chapter 9, Block Operation)

Fault Pressure Switch:

No signal from pressure switch

during pump cycle.

Fault Low Level:

The level in the reservoir has

fallen below the minimum fill

level. The further operational

sequence has been stopped.

15. Operational and pump faults

KFGC

Loading...

Loading...