TP303 – Operation, Maintenance and Instructions Manual

3.12

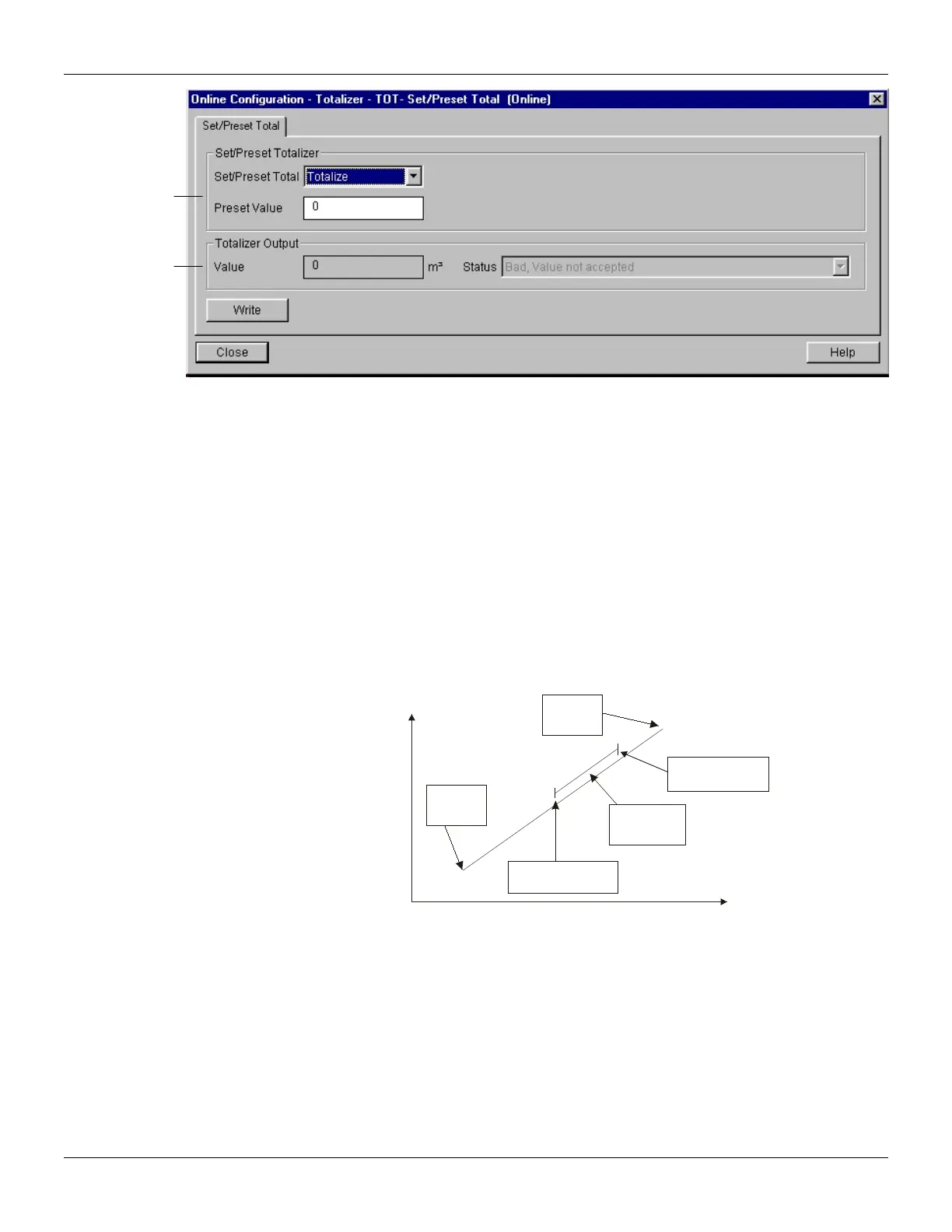

Figure 3.10 - Simatic PDM - Online Configuration - Set/Preset for Totalizer Block

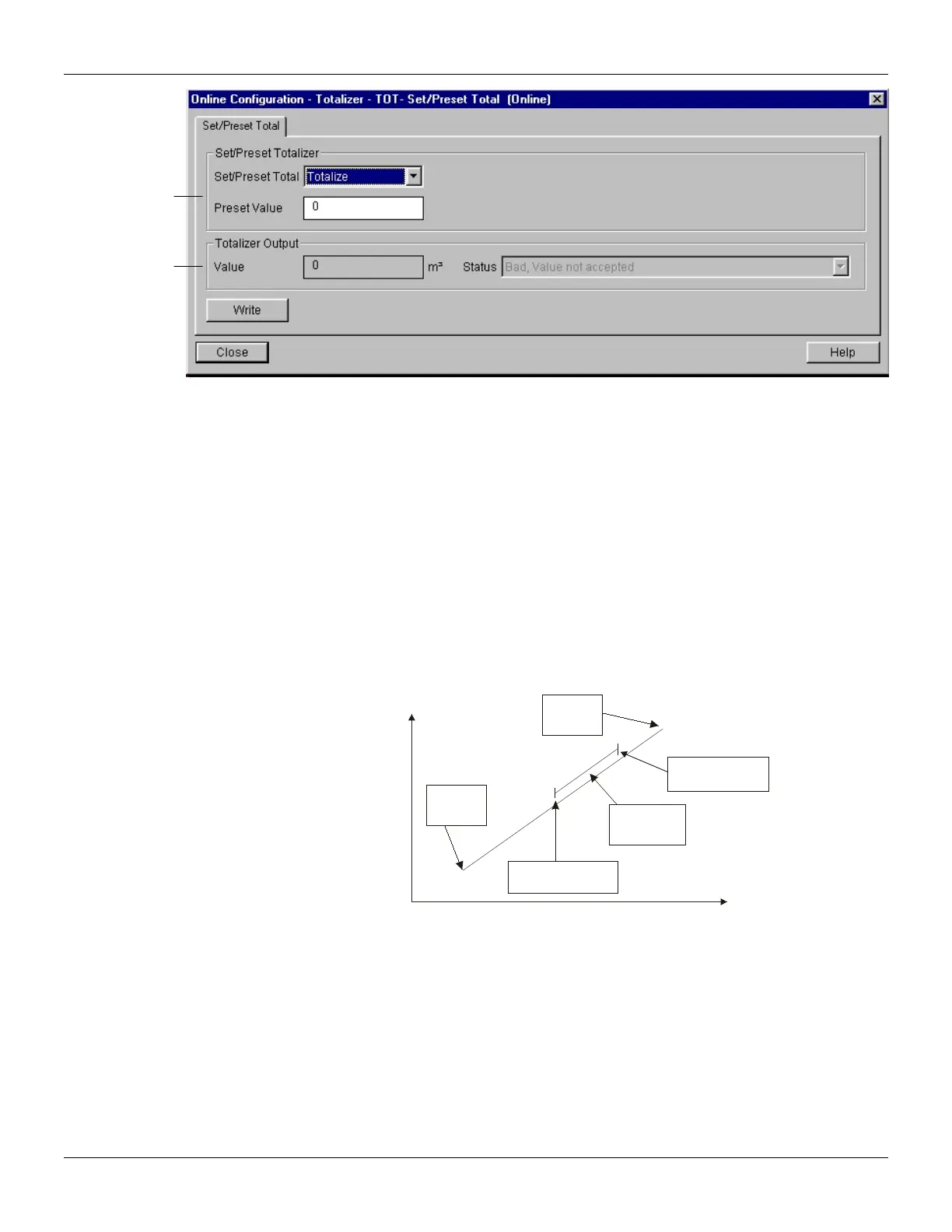

Lower and Upper Trim

This information is provided to recommend parameters for a common user calibration method for

position device.

The calibration process is used to match the channel value reading with the applied position input.

Six parameters are defined to configure this process: CAL_POINT_HI, CAL_POINT_LO,

CAL_MIN_SPAN, SENSOR_UNIT, SENSOR_HI_LIM and SENSOR_LO_LIM. The CAL_*

parameters define the highest and lowest calibrated values for this sensor, and the minimum

allowable span value for calibration. SENSOR_UNIT allows the user to select different units for

calibration purposes than the units defined by PRIMARY_VALUE_UNIT.

The SENSOR_HI_LIM and SENSOR_LO_LIM parameter defines the maximum and minimum

values the sensor is capable of indicating, according to SENSOR_UNIT used as it can be seen at

figure below.

Sensor

Lo Lim

Sensor

Hi Lim

CAL_POINT_LO

0.0 %

CAL_POINT_HI

100.0 %

TRIMMED VALUE

SENSOR VALUE

Calibrated

Range

Figure 3.11 - Hall Sensor Calibration

The trim is used to match the reading value with the applied position.

Lower Trim: It is used to trim the reading at the lower range. The operator informs to the TP303 the

correct reading for the position.

Upper Trim: It is used to trim the reading at the upper range. The operator informs to the TP303 the

correct reading for the position.

Using a configurator is possible to calibrate the converter by means of parameters CAL_POINT_LO

and CAL_POINT_HI. This engineering unit is configured by SENSOR_UNIT parameter. The unit

code is %. The calibrated value can be read by means TRIMMED_VALUE.

totalize, reset and

enter the value for

The user can monitor

Loading...

Loading...