5 Troubleshooting

-110-

No.PS※※-OMW0009-A

Troubleshooting

If an operation failure of the product occurs, please confirm the cause of the failure from the following table.

If a cause applicable to the failure cannot be identified and normal operation can be recovered by

replacement with a new product, this indicates that the product itself was faulty.

Problems with the product may be due to the operating environment (installation etc). Please consult SMC.

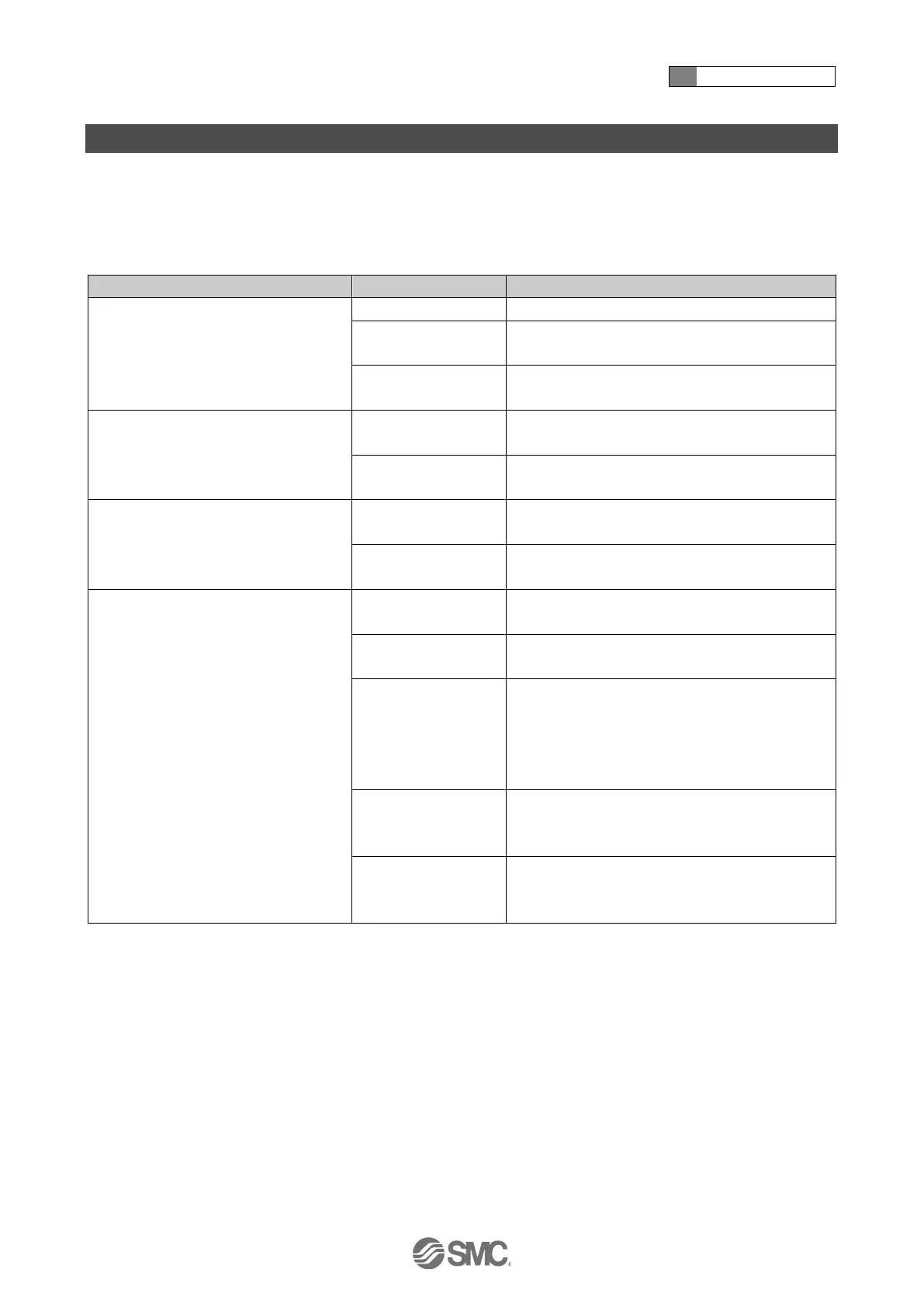

○Cross-reference for troubleshooting

Supply rated pressure. (100 kPa to 200 kPa)

Perform setting correctly.

(Refer to page 44)

Connect piping correctly and eliminate any air

leakage.

Output stays ON (Does not turn OFF)

Perform setting correctly.

(Refer to page 44)

Apply pressure lower than the withstand pressure

to eliminate the cause of clogging of piping.

The indicator LED operates correctly.

Output does not turn ON

Connect wires correctly.

(Refer to page 36)

Output specification

setting error

Check if the output specification (NPN/PNP) is

correct.

The Gap cannot be detected correctly.

Incorrect supply

pressure

Supply rated pressure. (100 kPa to 200 kPa)

Nozzle shape is not

correct

Correct the nozzle shape.

(Refer to page 29)

Multiple detection

nozzles are used

Do not use multiple detection nozzles with one

product.

If multiple nozzles are to be used, please test them

on the actual equipment. It is necessary for the

user to verify correct operation.

Equipment or fittings

causing leakage or

resistance are used

Do not use equipment or fittings that may leak or

obstruct the air flow between the product and the

detection nozzle.

The product is not

higher than the

detection nozzle

The product should be positioned higher than the

detection nozzle.

If the troubleshooting of ISA3 does not solve the problems, it is possible that the regulator or 2 port solenoid

valve has problems. Take appropriate corrective action by referring the troubleshooting for the regulator and 2

port solenoid valve.

Loading...

Loading...