∗ Numerical values other than “Moving force,” “Area 1,” and “Area 2” can be used to perform operation under numerical instructions from JXCL.

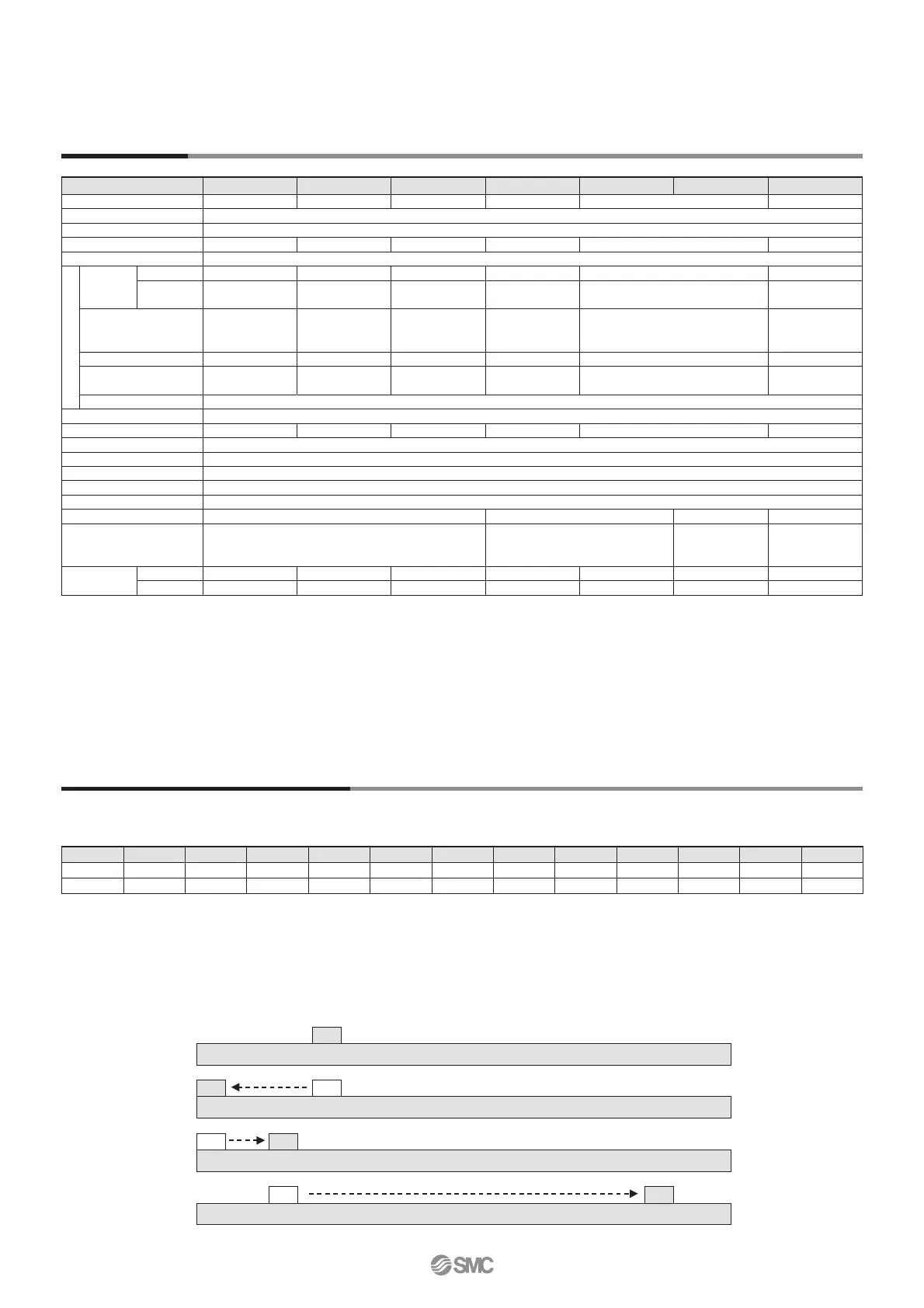

Specifi cations

Model

JXCE1 JXC91 JXCP1 JXCD1 JXCL1 JXCLF JXCM1

Network EtherCAT EtherNet/IP™ PROFINET DeviceNet

®

IO-Link CC-Link

Compatible motor Step motor (Servo/24 VDC)

Power supply Power voltage: 24 VDC ±10%

Current consumption (Controller)

200 mA or less 130 mA or less 200 mA or less 100 mA or less 100 mA or less 100 mA or less

Compatible encoder Incremental/Battery-less absolute

Communication specifi cations

Applicable

system

Protocol EtherCAT

∗

2

EtherNet/IP™

∗

2

PROFINET

∗

2

DeviceNet

®

IO-Link CC-Link

Version

∗

1

Conformance Test

Record V.1.2.6

Volume 1 (Edition 3.14)

Volume 2 (Edition 1.15)

Specifi cation

Version 2.32

Volume 1 (Edition 3.14)

Volume 3 (Edition 1.13)

Version 1.1

Port Class A

Ver. 1.10

Communication

speed

100 Mbps

∗

2

10/100 Mbps

∗

2

(Automatic

negotiation)

100 Mbps

∗

2

125/250/500 kbps

230.4 kbps

(COM3)

156 kbps, 625 kbps,

2.5 Mbps, 5 Mbps,

10 Mbps

Confi guration fi le

∗

3

ESI fi le EDS fi le GSDML fi le EDS fi le IODD fi le CSP+ fi le

I/O occupation area

Input 20 bytes

Output 36 bytes

Input 36 bytes

Output 36 bytes

Input 36 bytes

Output 36 bytes

Input 4, 10, 20 bytes

Output 4, 12, 20, 36 bytes

Input 14 bytes

Output 22 bytes

1 station, 2 stations,

4 stations

Terminating resistor Not included

Memory EEPROM

LED indicator

PWR, RUN, ALM, ERR

PWR, ALM, MS, NS

PWR, ALM, SF, BF

PWR, ALM, MS, NS

PWR, ALM, COM

PWR, ALM, L ERR, L RUN

Cable length [m] Actuator cable: 20 or less

Cooling system Natural air cooling

Operating temperature range [°C]

0 to 55 (No freezing)

∗

4

Operating humidity range [%RH]

90 or less (No condensation)

Insulation resistance [MΩ]

Between all external terminals and the case: 50 (500 VDC)

Safety function — — STO, SS1-t —

Safety standards ——

EN 61508 SIL 3

∗

5

EN 62061 SIL CL 3

∗

5

EN ISO 13849-1 Cat. 3 PL e

∗

5

—

Weight [g]

Screw mounting

220 210 220 210 190 220 170

DIN rail mounting

240 230 240 230 210 240 190

∗1 Please note that versions are subject to change.

∗2 Use a shielded communication cable with CAT5 or higher for the PROFINET, EtherNet/IP™, and EtherCAT.

∗3 The fi les can be downloaded from the SMC website.

∗4 The operating temperature range for both controller version 1 products and controller version 2 products is 0 to 4 0 °C. Refer to the Web Catalogue for

details on identifying controller version symbols.

∗5 The above safety integrity level is the max. value. The achievable level varies depending on the confi guration and inspection method of the component.

Be sure to refer to “Safety Manual: JXC#-OMY0009” for more information.

Trademark

EtherNet/IP

®

is a registered trademark of ODVA, Inc.

DeviceNet

®

is a registered trademark of ODVA, Inc.

EtherCAT

®

is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

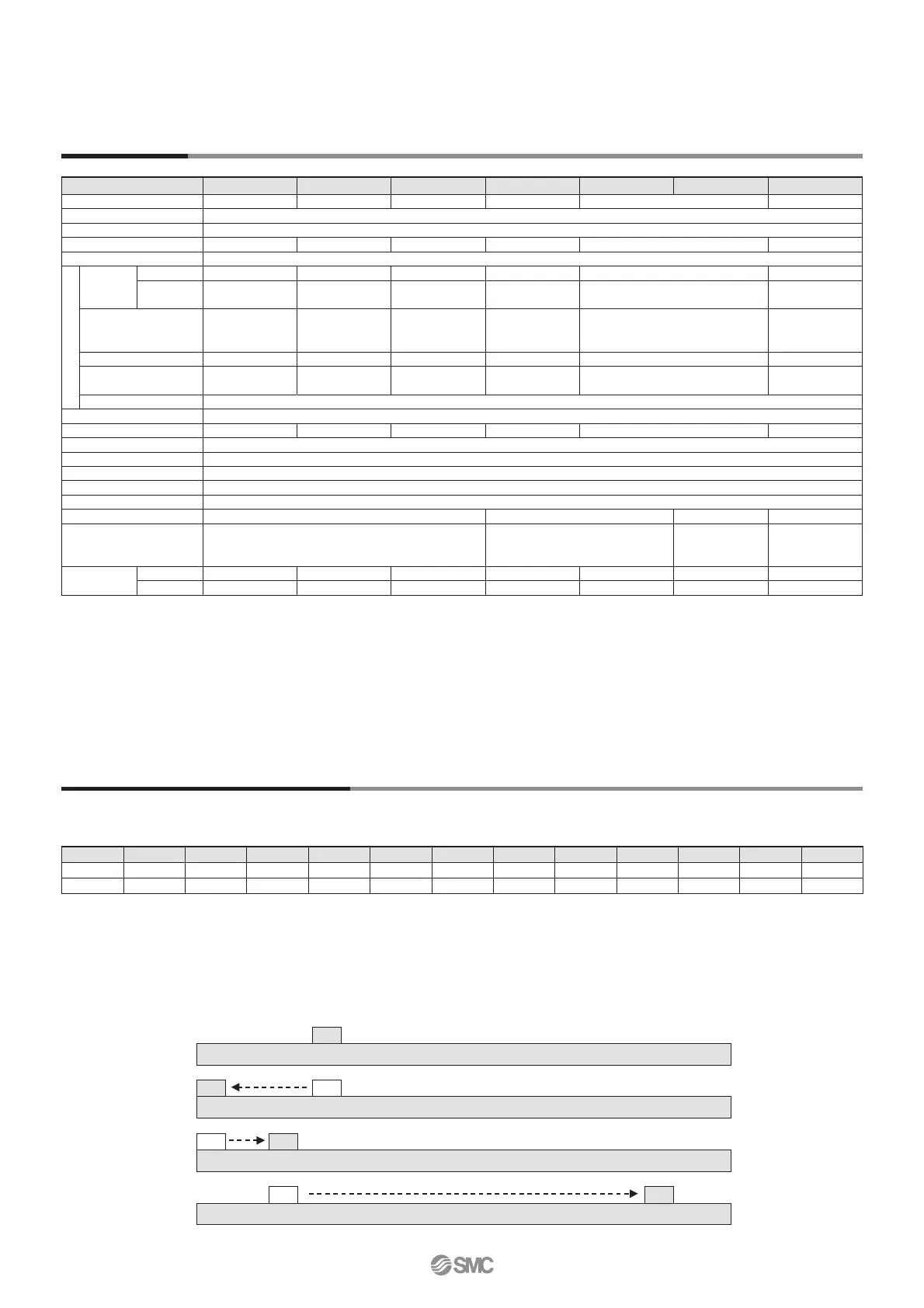

Example of Operation Command

In addition to the step data input of 64 points maximum in each communication protocol, the changing of each parameter can be performed in real time via numerical data defi ned operation.

<Application example> Movement between 2 points

No.

Movement mode

Speed Position

Acceleration

Deceleration

Pushing force

Trigger LV

Pushing speed

Moving force

Area 1 Area 2 In position

0

1: Absolute

100 10 3000 3000 0 0 0 100 0 0 0.50

1

1: Absolute

100 100 3000 3000 0 0 0 100 0 0 0.50

<Step no. defi ned operation>

Sequence 1: Servo ON instruction

Sequence 2: Instruction to return to origin

Sequence 3: Specify step data No. 0 to input the DRIVE signal.

Sequence 4: Specify step data No. 1 after the DRIVE signal has been

temporarily turned OFF to input the DRIVE signal.

<Numerical data defi ned operation>

Sequence 1: Servo ON instruction

Sequence 2: Instruction to return to origin

Sequence 3:

Specify step data No. 0 and turn ON the input instruction fl ag (position).

Input 10 in the target position. Subsequently the start fl ag turns ON.

Sequence 4:

Turn ON step data No. 0 and the input instruction fl ag (position)

to change the target position to 100 while the start fl ag is ON.

The same operation can be performed with any operation command.

0 10 100

Sequence 1J

Sequence 2J

Sequence 3J

Sequence 4J

19

JXCE1/91/P1/D1/L/M1 Series

Loading...

Loading...