■After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid.

When leakage occurs from parts other than the piping, the product might be faulty.

Disconnect the power supply and stop the fluid supply.

Do not apply fluid under leaking conditions.

Safety cannot be assured in the case of unexpected malfunction.

■NOTE

○Follow the instructions given below when designing, selecting and handling the product.

●The instructions on design and selection (installation, wiring, environment, adjustment, operation,

maintenance, etc.) described below must also be followed.

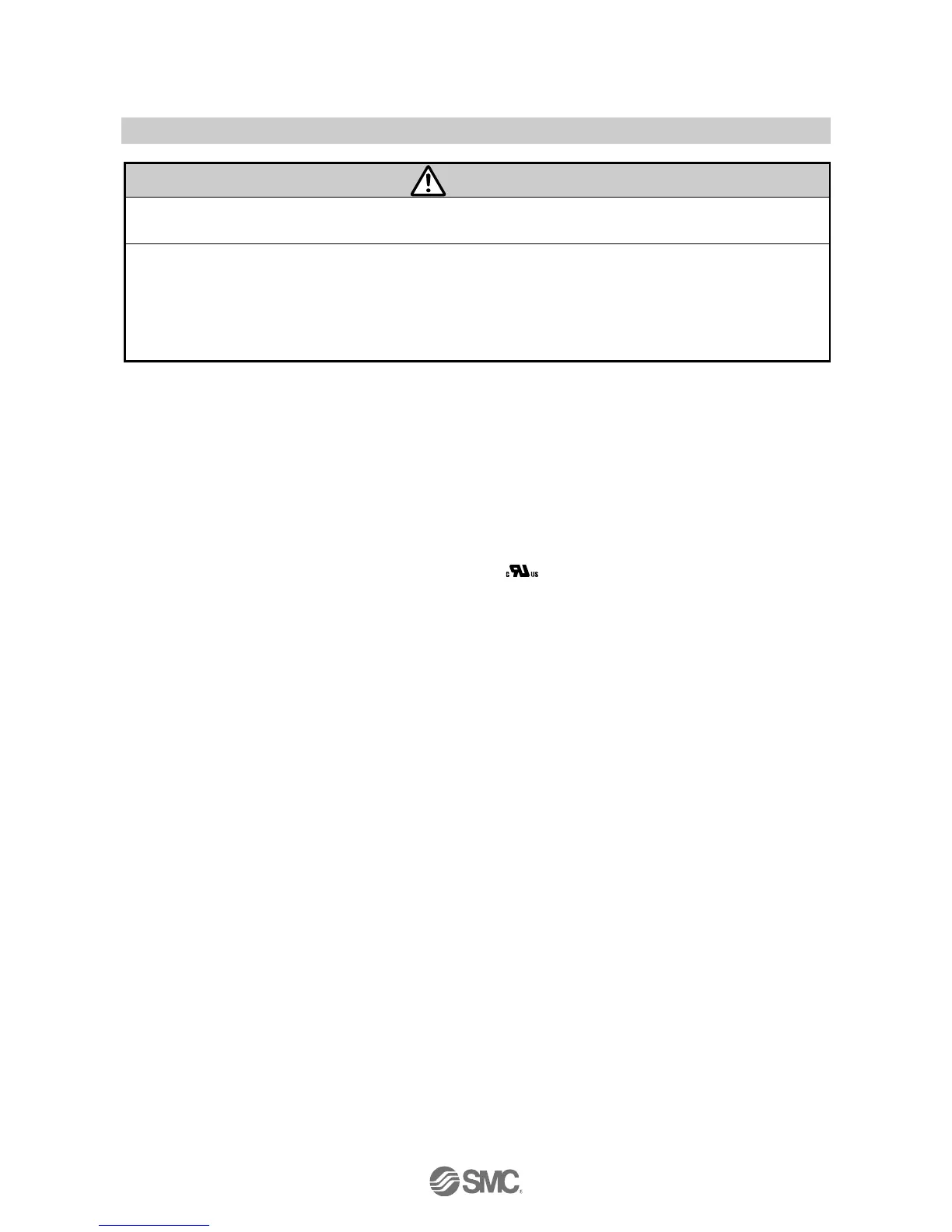

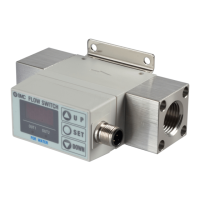

Product specifications

The direct current power supply used should be UL approved as follows.

Circuit (Class 2) of maximum 30 Vrms (42.4 V peak) or less, with UL1310 Class 2 power supply unit or UL1585

Class 2 transformer.

The product is a UL approved product only if it has a mark on the body.

Use the specified voltage.

Otherwise failure or malfunction can result.

Insufficient supply voltage may not drive a load due to a voltage drop inside the product.

Verify the operating voltage of the load before use.

Do not exceed the specified maximum allowable load.

Otherwise it can cause damage or shorten the lifetime of the product.

Data stored by the product is not deleted, even if the power supply is cut off.

(Writing time: 1000000 cycles, Data duration: 20 years after power off.)

Applicable operating fluid depends on the product.

Check the details of the specifications before using.

Before designing piping confirm the pressure loss at the sensor from the pressure loss graph.

Confirm pressure loss of the sensor from the characteristics data.

For the details of compressed air quality, refer to ISO 8573-1, 1.1.2 to 1.6.2.

Use the specified measurement flow rate and operating pressure.

Otherwise it can cause damage to the product or inability to measure correctly.

Reserve a space for maintenance.

Allow sufficient space for maintenance when designing the system.

Loading...

Loading...