Installation

4

INSTALLATION

This section assumes that the site meets the requirements.

The iSTAR Ultra does not include mounting hardware. See Tab le 2 on page 3

for more detail.

Wall Mount Installation

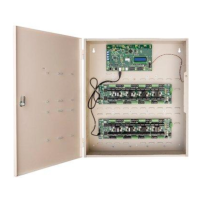

The most common installation is the wall mount. In this installation, the

enclosure is mounted directly to a wall or uni-strut using suitable user-supplied

hardware. See Tab l e 2 on page 3 for more detail.

Requirements:

The anchoring system must be capable of sustaining 75 lb (34 kg). This

weight does not include the cables.

The cables are protected by use of conduit, which is metal, plastic, or

flexible.

ACM cabling must be shielded.

An external power supply provides 12 Vdc to run the logic of the iSTAR and

the read heads. There is an option for two external power supplies to supply

the locks using wet relays. The lock power supplies are rated at 0 - 30 Vdc,

but are usually 12 Vdc or 24 Vdc. In some installations, the locks can be two

12 Vdc or two 24 Vdc, or either combination of both voltages.

If an ACM is powered by a different PSU, the ACM Fail trigger must be

configured to alarm on failure.

The enclosure has knock-outs for installing and removing wires in and out of

the wall mount enclosure.

The enclosure door supports up to four accessary boards (I/8, I/8-CSI, R/8,

RM-4E), see

ELECTROSTATIC SENSITIVE DEVICES: Observe precautions for handling.

Before handling any internal components, discharge static electricity by

holding a grounding lug or non-painted surface for three seconds.

Wear a grounding wrist strap and stand on a grounded static mat.

Reduce movement during installation to reduce static buildup.

Make sure work area is safeguarded.

Transport components in static-shielded containers.

Note: The outside of the ESD bags are not ESD protective.

Verify that all components, materials, and the installer are referenced to a

common ground.

Loading...

Loading...