29 • Recommended Wiring diagrams

________________________________________________________________________________________________

4.18 Short Circuit Protection

For “type 2 coordination

”, use fuses for semiconductor protection to protect the RVS-DN from a short circuit.

Fuses for semiconductor protection give excellent results because they have low I²t values and high

interruption ratings.

Recommended fuse selection procedure:

(1) Fuse rated voltage

: Choose minimum fuse rated voltage which is above the rated voltage of the

mains.

(2) Fuse rated current:

Select a fuse which is able to carry 8 times the rated RVS-DN current for 30

seconds (this is double the maximum RVS-DN current for the maximum acceleration time).

(3) Fuse I²t:

Verify that the I²t value of the fuse is less than or equal to the I²t value of the thyristor in the

RVS-DN as shown in the table below.

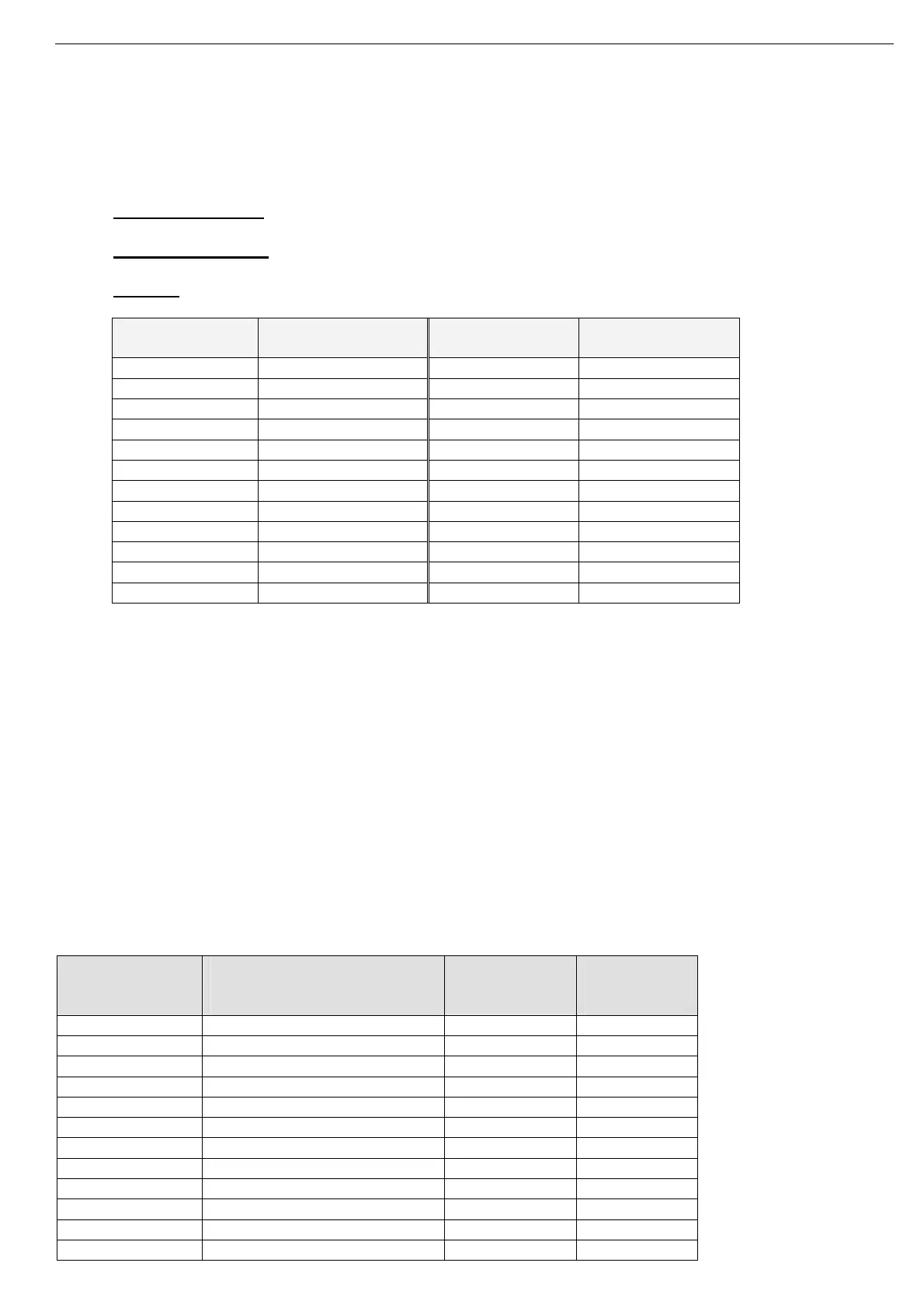

RVS-DN Model Max. Thyristor I

2

t

[A2Sec]

RVS-DN Model Max. Thyristor I

2

t

[A2Sec]

8 400 390 700,000

17 5,000 460 800,000

31 10,000 580 1,200,000

44 12,000 820 2,000,000

58 15,000 950 4,500,000

72 18,000 1100 4,500,000

85 50,000 1400 6,500,000

105 60,000 1800 12,500,000

145 100,000 2150 16,500,000

170 140,000 2400 26,000,000

210 200,000 2700 26,000,000

310 600,000 3000 Consult factory

4.19 Transient Protection

Line transie

nt voltages can cause a malfunction of the RVS-DN and damage to the thyristors. All RVS-DNs

incorporate Metal Oxide Varistors (MOV) to protect from normal line voltage spikes.

When higher transients are expected, additional external protection should be used (consult factory).

4.20 UL, cUL Installation Instructions

1.

Input power and output motor field wiring shall be copper conductors, rated 75°C.

2. Use UL listed closed-loop connectors sized for the selected wire gauge. Install connectors using the

correct crimp tool recommended by the connector manufacturer. Applies only to units bus bars.

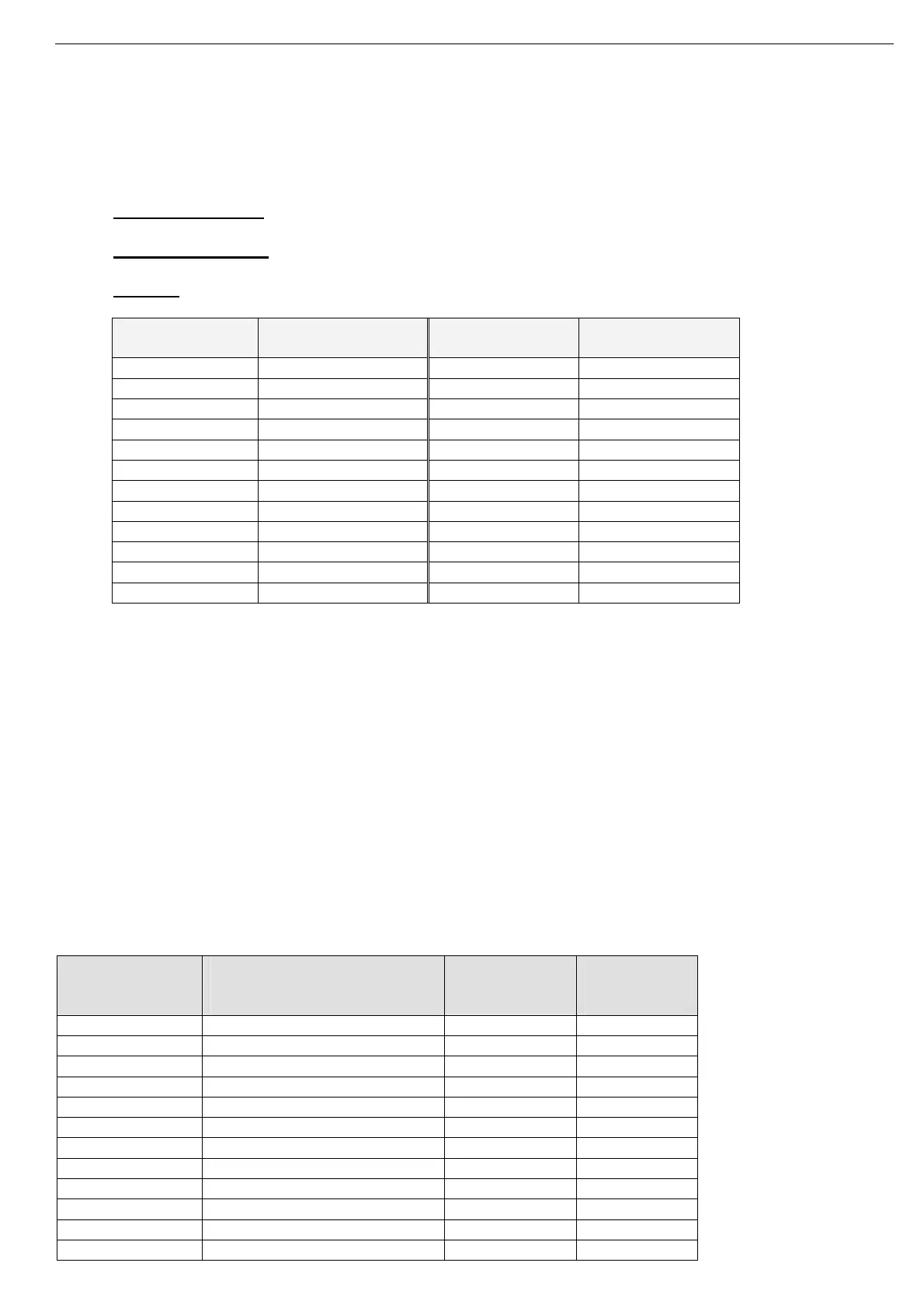

3. Table showing corresponding wire size, terminal screw, closed-loop connector size. Torque ratings for

attachment of connector to bus bar (see table).

4. Branch circuit protection, shall be provided per the NEC.

For units with UL cUL, see ordering information.

Cables, Terminal Screws and Torque Recommendations

Max. Motor FLA

[A]

Min. Dimensions for

Copper Cables

[mm

2

]

Terminal

Screw

Mechanical

Torque

[Nm]

8 4 x 1.5 N2XY M5 3

17 4 x 2.5 N2XY M5 3

31 4 x 4 N2XY M5 3

44 4 x 10 N2XY M6 4.5

58 4 x 16 N2XY M6 4.5

72 4 x 16 N2XY M6 4.5

85 4 x 25 N2XY M8 15

105 4 x 35 N2XY M8 15

145 3 x 50 + 25 N2XY M8 15

170 3 x 70 + 35 N2XY M10 30

210 3 x 95 + 50 N2XY M10 30

310 3 x 150 + 70 N2XY M12 60

Loading...

Loading...