25

Original document - Mi-205 EN Edition: 2021-04

•

Check if all screws of the cover plate are tightened.

Do not pull the ends of the counterflange with force to the valves, to compensate wide clearances

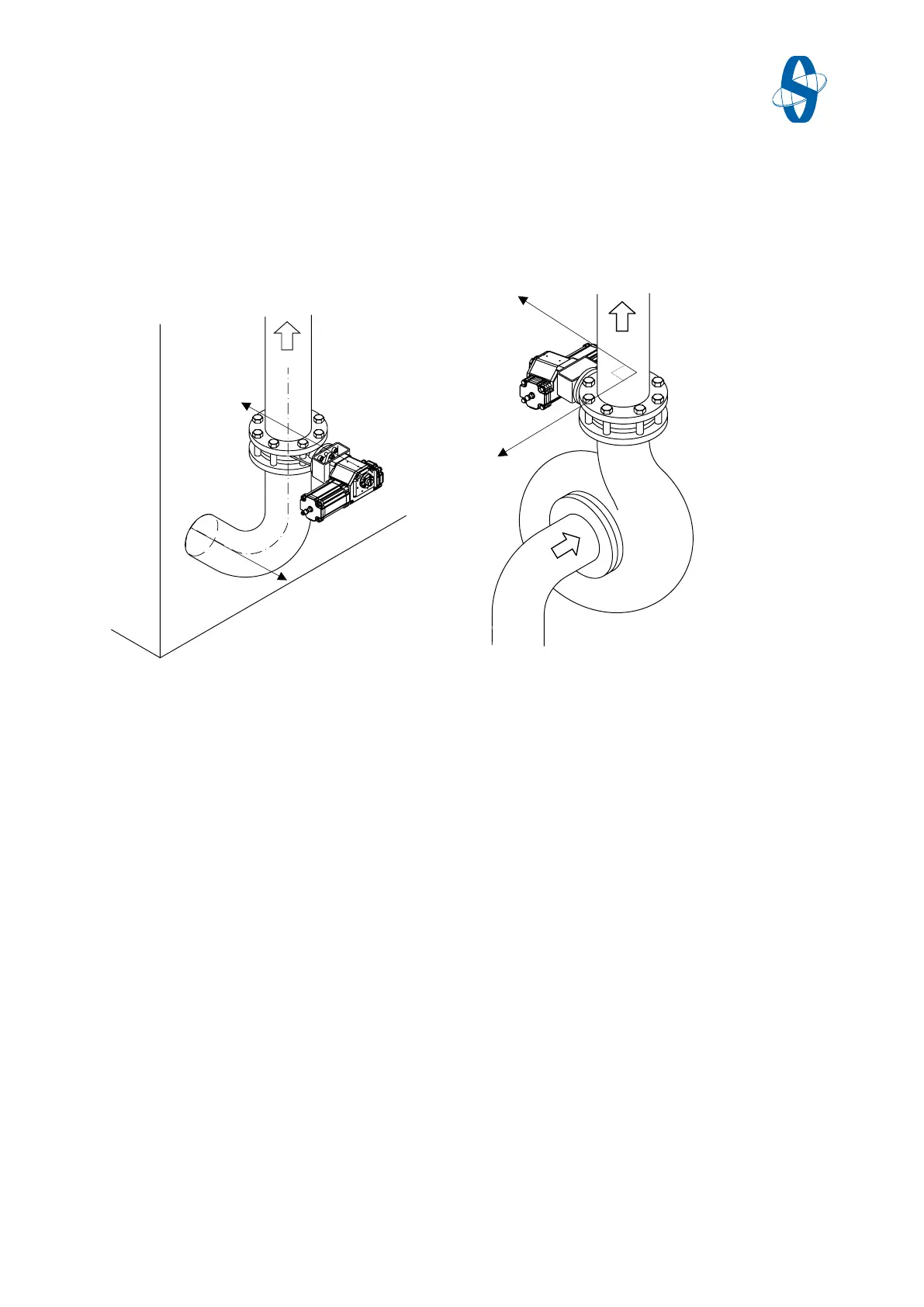

In case of control application avoid mounting the butterfly valve direct behind or ahead of a pipe

bend. If the valve must be mounted behind a pipe bend, observe that the shaft is assembled aligned

to the bend to reduce dynamic, irregular forces on the butterfly (

➔ Fig.5-4).

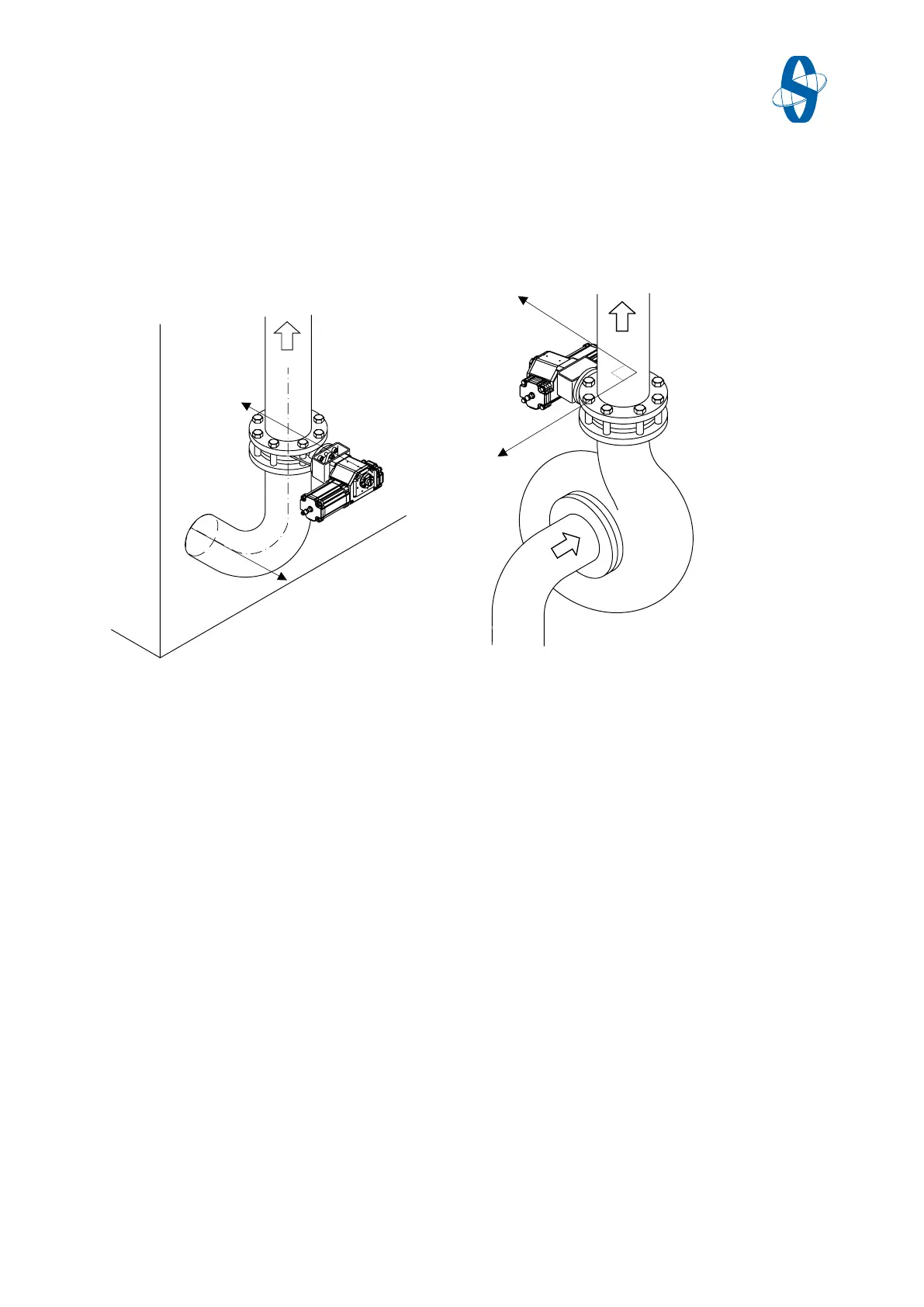

Fig.5-4 Installing near pipe bends Fig.5-5 Installing the butterfly valve after a centrifugal pump

To install the butterfly valve on the pressure side of a centrifugal pump, you have to position the

butterfly valve shaft perpendicular to the pump shaft (

➔ Fig.5-5).

1. Make sure that the pipelines are flushed clean.

2. Open and close the valve completely before tightening the screws of the flange. Consider that

the butterfly valve opens 60°-80° by control applications and about 80° by shut-off function. To

seal the flanges tightly you have to use plain washers and tighten the screws in sequence with a

torque wrench. The fastening torque depends on the size of the screw (

➔ Chap. 4.2).

3. If possible open the valve approx. 5° right before installing.

4. Make sure that the sealing areas of the counterflange are clean and parallel situated.

5. Make sure that the butterfly valve and the gaskets are correctly centered and that correct quality

is used. By a good shut-off function the pressure of the counterflange is transmitted through the

gasket to the cover plate (

➔ Fig.5-6).

6. Tightening torque varies with the bolt dimension acc. to table (

➔ Chap. 4.2).

7. The flange bolts must be tightened cross-wise acc. (

➔ Fig.5-7)

8. NOTE! On the MTVL/FSVL valves, the bolts are first tightened on the cover plate side (inlet).

Loading...

Loading...