18

HCD-GX470/GX570

VERSION DISPLAY MODE

This mode is used to check the model, destination and software

version.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of s , 7 and [DISC 2] simultaneously.

3. Fluorescent indicator tube, and LEDs are all turned on.

4. Press the [REC PAUSE/START] button to display the software

version and year, month, day of the software creation.

5. Press the [CD SYNC] button to display the model and destination.

6. To release this mode, press three buttons of s , 7 and

[DISC 2] simultaneously.

CD ERROR CODE DISPLAY MODE (GX470 ONLY)

This mode can be used for error code display of CD section.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [CD] button to select “CD”.

3. Press three buttons of s , [CD] and [DISC 1] simultaneously.

4. When this mode is activated, mechanism deck error code is

displayed on the fluorescent indicator tube.

5. Press the [REC PAUSE/START] button to changed over between

optical pick-up error code display mode and mechanism deck

error code mode.

6. Turn the multi jog knob to change over display of error history.

7. To release this mode, press the I/1 button to turn the power

off.

1. Mechanism Deck Error Code Mode

When this mode is entered, mechanism deck error code is displayed

with the 10-character format on the fluorescent indicator tube.

The first digit from the left indicates:

The first digit from the left indicates which mode the error history

is. In the mechanism deck error code mode, “M” is displayed on

the fluorescent indicator tube.

The second digit from the left indicates:

(Error history number display)

The second digit from the left indicates which order the error history

is. “1” indicates the latest error history, and each time the number

increases by one, the error history goes back to one-previous error.

The third and 4th digit from the left indicates:

(Error status display)

The third and 4th digit from the left indicates which error status is

indicated.

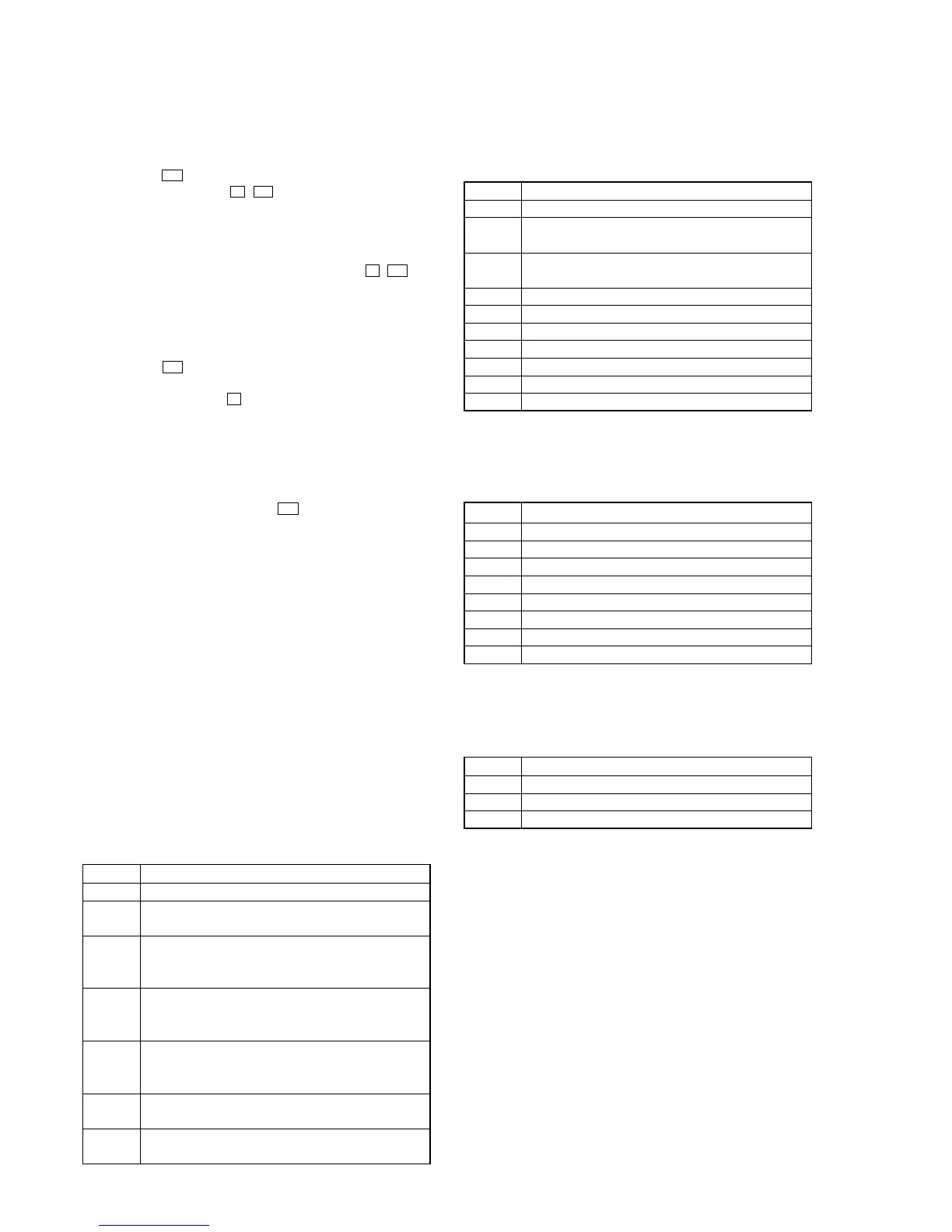

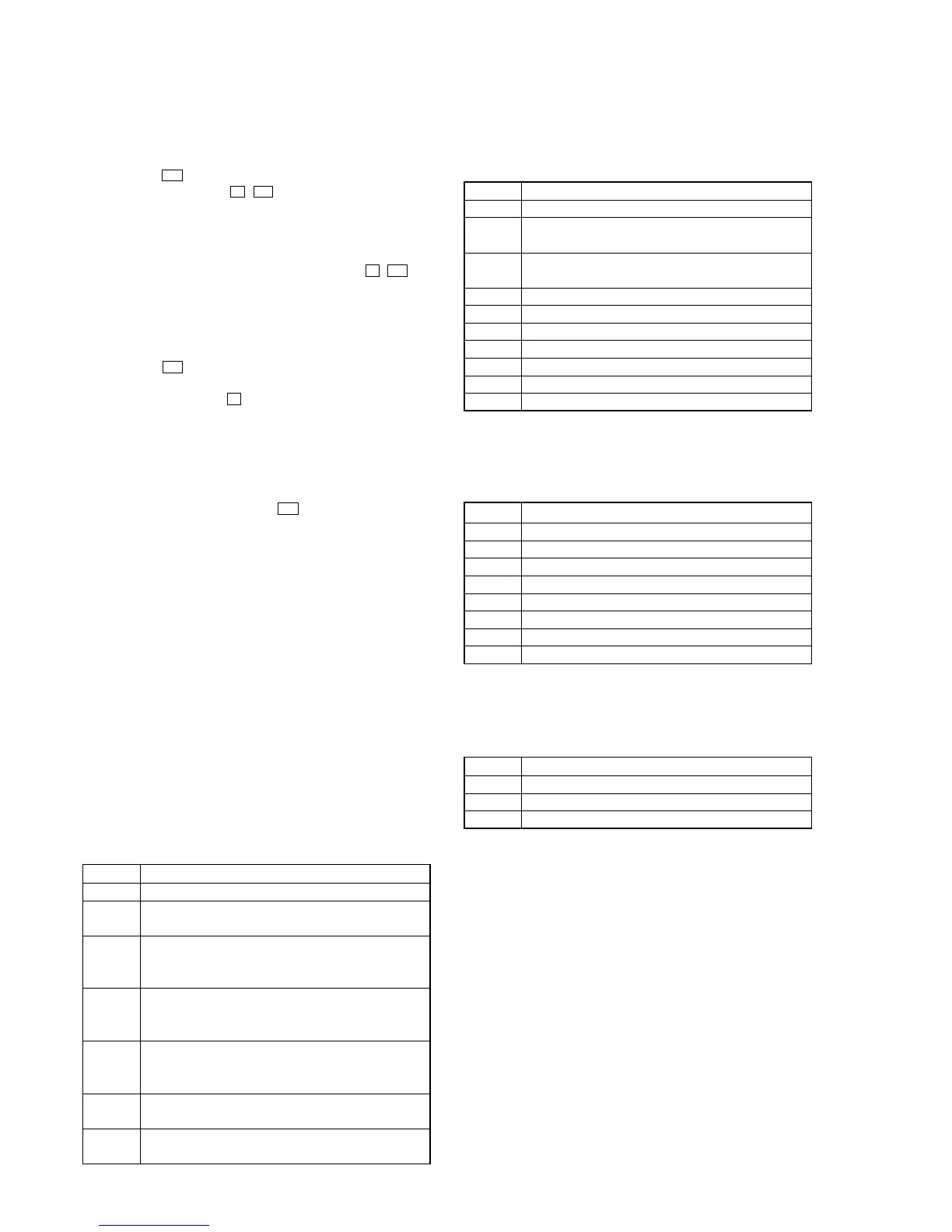

Display Status

00 No error

08 Table operation time-out (Table does not move to the target

position within the specified time)

16 In the chucking down operation, the operation was retried

by the maximum number of times but the operation could

not be completed

17 In the chucking up and down operation, the reverse

recovery processing was attempted but it could not be

recovered

18 In the chucking up operation, the operation was retried by

the maximum number of times but the operation could not

be completed

20 Loading operation time-out (Table does not move to the

target position within the specified time)

22 As the chuck was in the ex-open status at the initialization,

the closing was attempted but could not be completed

The 5th and 6th digit from the left indicates:

(Present status display)

The 5th and 6th digit from the left indicates which operating status

when an error occurred is indicated.

Display Status

01 Open completion status

02 From open status, the movement to chucking down position

is under way

03 From chucking down position, the open operation is under

way

04 Chucking down completion status

10 The chucking down operation is under way

11 The chucking up operation is under way

12 Close completion status

13 From close status, the ex-open operation is under way

14 From ex-open status, the close operation is under way

18 Ex-pen completion status

The 7th and 8th digit from the left indicates:

(Motor status display)

The 7th and 8th digit from the left indicates which motor output

status when an error occurred is indicated.

Display Status

× 0 No table motor output

× 1Table motor forward output

× 2Table motor backward output

× 3Table motor break output

0 × No loading motor output

1 × Loading motor forward output

2 × Loading motor backward output

3 × Loading motor break output

The 9th and 10 th digit from the left indicates:

(Tray status display)

The 9th and 10th digit from the left indicates which target processing

when an error occurred is indicated.

Display Status

01 Open operation

12 Close operation

18 Ex-open operation

Loading...

Loading...