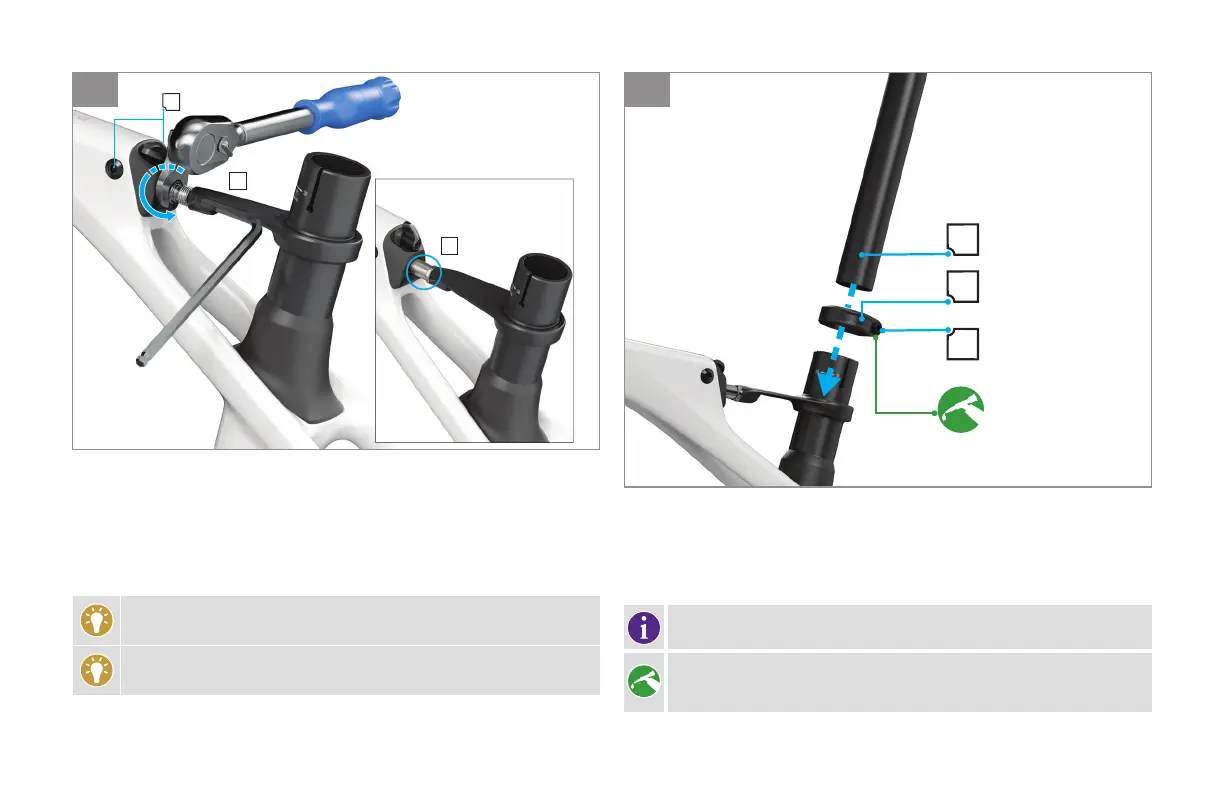

26

C

A

B

7

FIG. 7

Insert a 5 mm L-shaped hex key to hold the tendon in place and use an 11 mm crow foot

wrench on the damper shaft to torque it to 6 Nm / 53 in-lbf (A).

Using a torque wrench and 4 mm hex bit, torque each of the damper bolts (B) you inserted

in FIG. 1 to 6 Nm / 53 in-lbf.

A properly connected damper and tendon is shown in C.

Use the flats on the shaft’s tool interface to apply rearward pressure on the

shaft while tightening.

Place a folded paper towel or clean rag on the frame under the damper and

tendon to prevent damage to the frame when torquing.

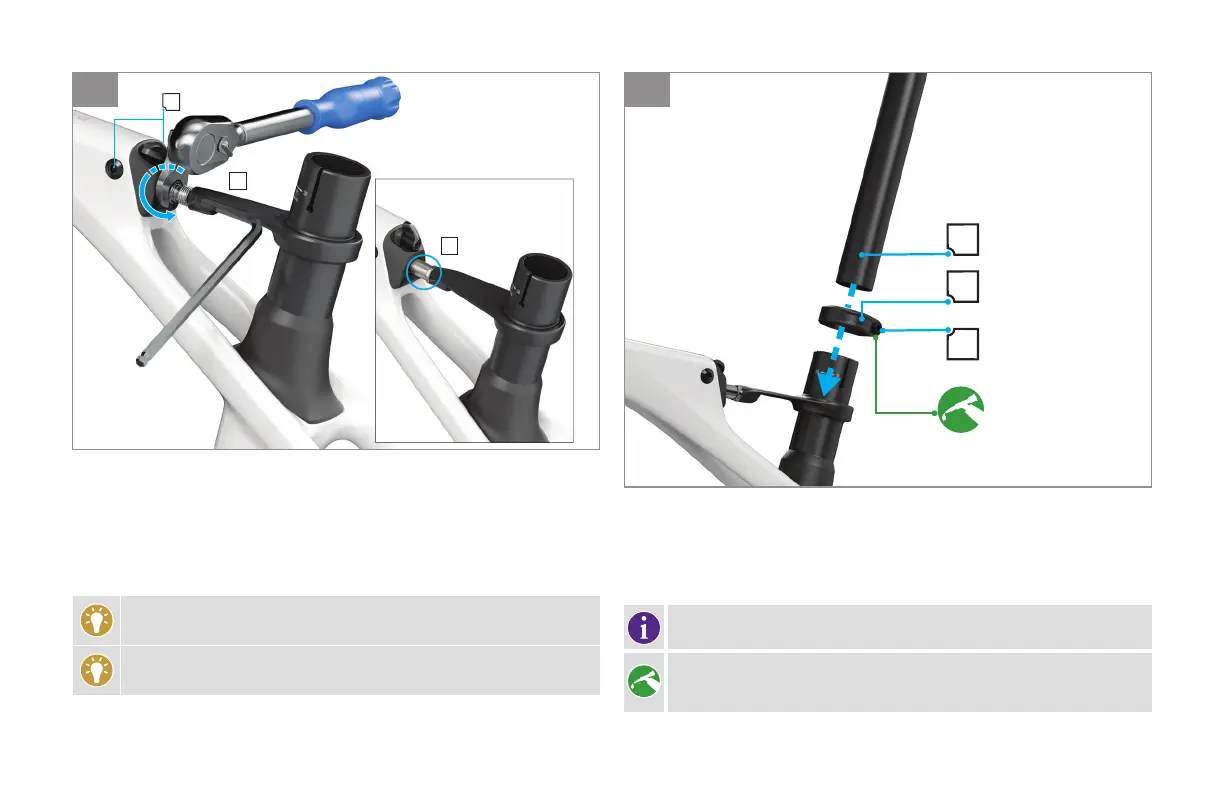

B

A

C

8

FIG. 8

Install the seatpost clamp bolt (C) into the seatpost clamp. Install the seatpost clamp (A)

and seatpost (B) onto the framepost with the seatpost clamp bolt facing backward.

Using a torque wrench and a 4 mm hex bit, torque the seatpost clamp bolt (C) to 6.2 Nm /

55 in-lbf.

Refer to section 6.4 for more information on seatpost minimum insertion.

The seatpost clamp bolt comes pre-greased. When adjusting the seatpost or

when changing out the framepost (section 7.6), grease the bolt if it appears

dry.

Loading...

Loading...