4.5.1 Wiring

The injectors have to be wired on the engine. Some of the kits include an injector harness like the

Lexus V8. Make sure that the combination of injectors is correct as this will influence consistency

between cylinders. Injectors come in 2 groups. High resistance (12 to 18 Ohm) and low resistance

(2 to 4 Ohm). For high resistance injectors you may add up to 4 injectors per channel. They are

always connected in parallel. Low resistor injectors however should be limited to one per channel.

Or they can be connected 2 in series. They should actually be connected to a different current

limiting driver. They may heat up if not properly cooled and eventually self-destruct. For injector

wiring see specific wiring details on the relevant wiring diagrams on CD.

4.5.2 Sequential injection

There are enough outputs available for 4 cylinder engines to do sequential injection and wasted

spark. Specific models only. This however will require a TDC signal indicating that cylinder 1 is on

firing and is normally obtained from a separate cam sensor. Here fuel is injected once every 2

RPM’s and always start at Bottom Deck Centre (BDC). Since there is not much to gain over the

next method, we design most of the software for Split-Sequential injection. Each injector has its

own driver from the ECU. See the specific wiring diagram.

4.5.3 Split-Sequential injection

The ECU is designed to do split-sequential injection. This method will inject on the two cylinders

that move up and down together. It will inject once per RPM and will start at BDC. Fuel is injected

very accurately and excellent CO adjustments can be achieved. The advantage of this method is

that each cylinder receives it fuel under the same conditions, resulting in very smooth idling and

revving. It is definitely better on power and consumption than the batch injection method. Injectors

are wired in the same sequence as wasted spark. Split the firing order in 2 and write se second

half next to the first half. See example. Then group the injectors using the first of both halves, then

the second then the third then the fourth. Two injectors are wired on each driver from the ECU. On

the CD are drawings for these injector combinations. See the chart below:

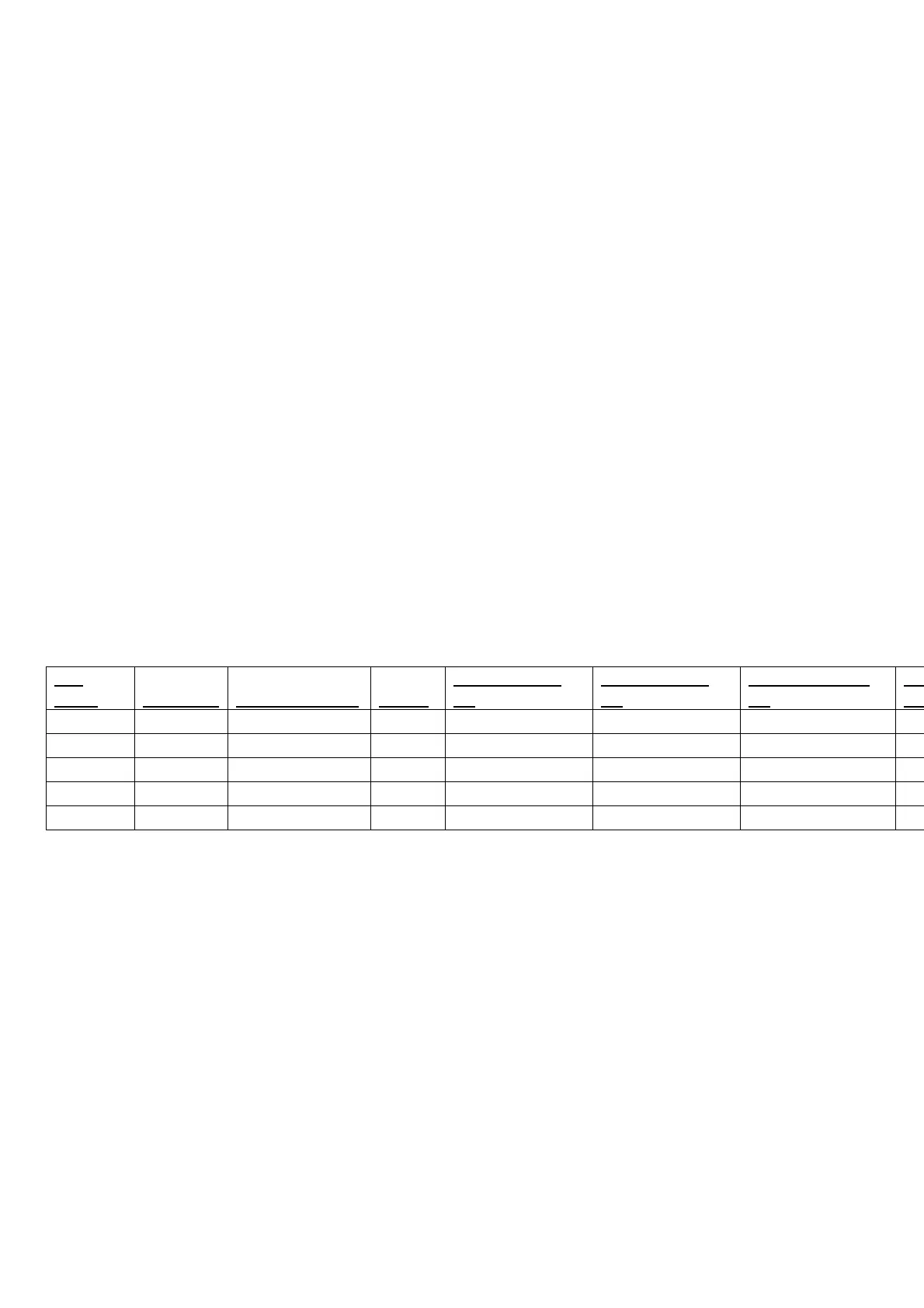

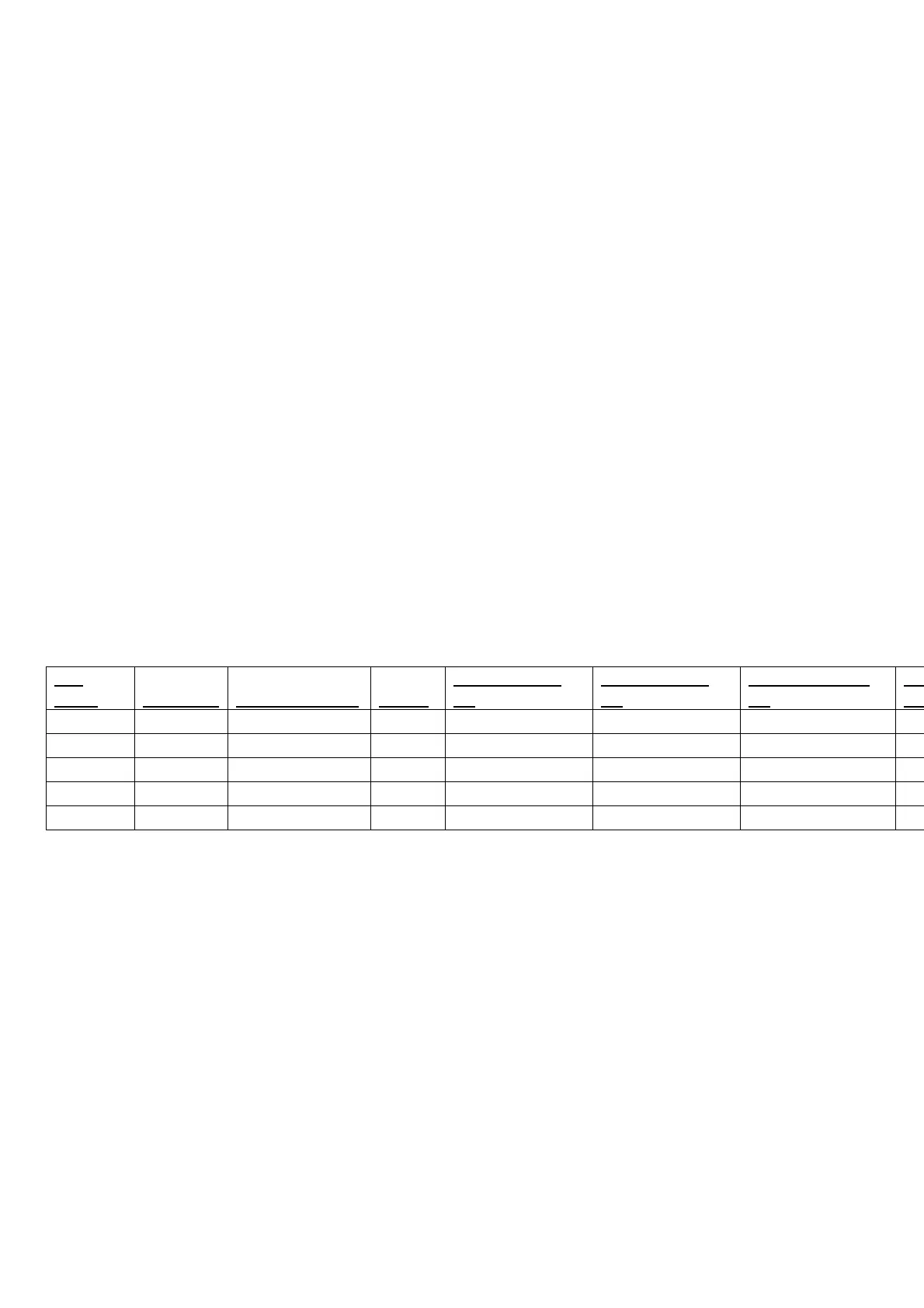

ECU

Driver WireColor FiringOrder4Cyl Subaru

FiringOrderV6

Cyl

FiringOrderV6

Cyl

FiringOrderStr6

Cyl

Fir

Ch

1342or1243 1324 123456 142536 153624 18

INJ1 White 1&4 1&2 1&4 1&5 1&6 1

INJ2 Black 2&3 3&4 2&5 4&3 5&2 8

INJ3 Green 3&6 2&6 3&4 4

INJ4 Yellow 3

Ex: Lexus V8 Firing order: 1 8 4 3 6 5 7 2

1 8 4 3 is 1&6 = White, 8&5 = Black, 4&7 = Green, 3&2 = Yellow

6 5 7 2

4.5.4 Batch fire

With this method, two injector drivers are being pulsed 180° out of faze. Although not preferred,

fuel metering and timing is done very accurately and should still give excellent results. Split the

injectors in two groups to divide the current on the 2 driver outputs. Put alternate numbers on the

firing order together to ensure a more even fuel distribution. For bigger engines keep the mean

supply current below 7A. More outputs are available in the intermediate and advance units. See

the specific wiring diagram.

4.5.5 Throttle Body Injection

With this method, injectors are situated at the throttle body. Spitronics do a Weber 2 Injector and a

Holley 4 Injector conversion. With these conversions injectors is situated on the top of the butterfly.

The ECU also has a special program to pulse these injectors in sequence and vary the pulses per

RPM to get a much smoother distribution of the fuel mixture. See the specific wiring diagram to

Loading...

Loading...