12

381497 USA 10-2014

APV

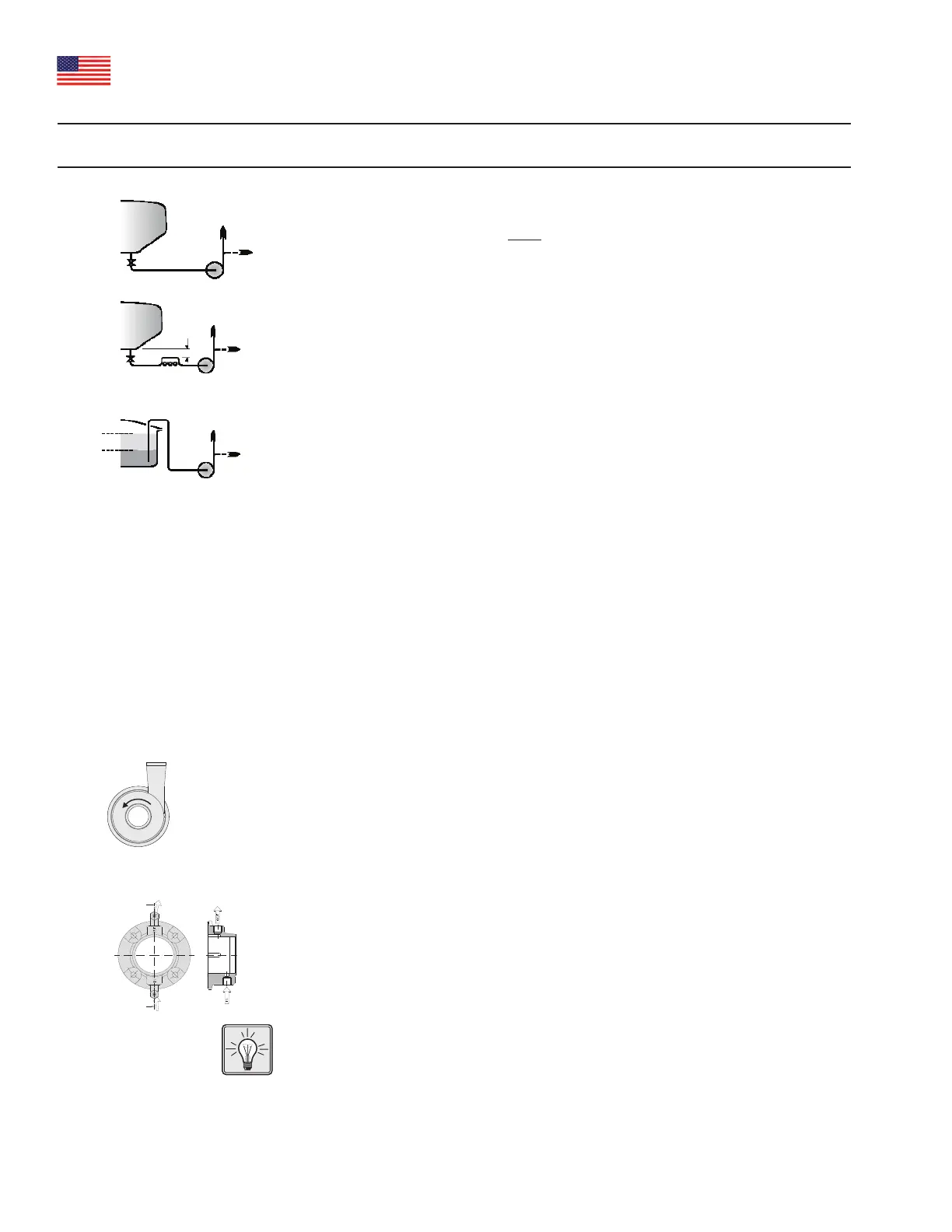

2.3 Installation of pump without recirculation.

In this application, where the simplified pipe layout is to be used, one

important requirement must be met:

As the suction tank starts to refill, some liquid will be able to flow from

the tank into the pump to replenish any priming liquid lost when the

tank was previously pumped dry. Typical applications can be seen in

Fig. 3.

Note: The pump body must always be mounted with outlet vertically

upwards and all the other conditions apply.

Note: Any eccentric reducer should be mounted such that the pump

center line is lower than the inlet pipe's center line.

2.4 Lining up the pipe system

Line up the pipes carefully to the pump suction and discharge ports.

Make sure that the pipe system is adequately supported by pipe

supports, so that the pump body is not subject to strains and weight

from the pipe system.

Note: During priming the pump may tend to vibrate. A pipe support

should be placed close to the pump suction to prevent pipework

vibration creating excessive noise.

2.5 Power supply

All electrical installation must comply with all applicable codes and

standards including those established by the Occupational Safety and

Health Administration (OSHA).

Install a main power disconnect on-off switch that can be locked in the

power off position and have the key removed when service is

performed.

Thoroughly read the motor manufacturer’s instructions before making

installation.

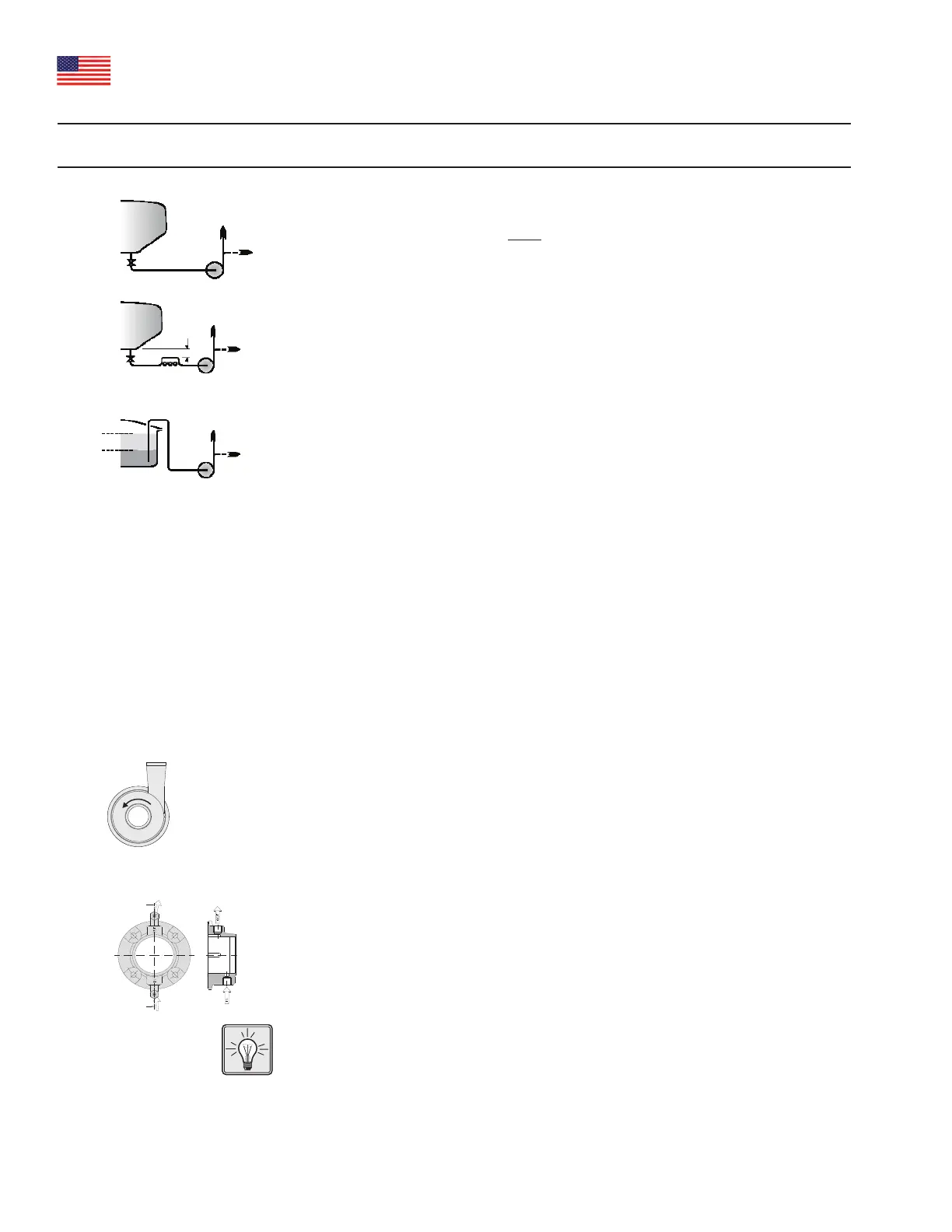

The motor should be connected such that the rotating direction of the

motor (and thus of the impeller) is counterclockwise when viewed from

the front towards the suction nozzle of the pump body (Fig. 4).

2.6 Water supply for water-flushed shaft seal

Pumps with a water-flushed shaft seal have two hose connectors on

the seal flange (Fig. 5). The hose connectors are 1/8 inch NPT and fit a

1/4 inch plastic tubing. A flush flow of 4-8 gallons/h is required.

Maximum pressure is 100 PSIG.

The hose connection in the seal flange should always be positioned

vertically with the fluid inlet underneath and the outlet on top.

Water consumption can be limited by installing a solenoid valve for the

flushing water on the supply side. The open/close function of the

solenoid valve can be controlled by the pump's start/stop sequence.

Before starting the pump, dismantle and clean the suction pipe. Any

foreign material in the pump must be removed.

(A)

(B)

(C)

20”

min.

Liquid level

High

Low

Fig. 3: Typical applications

Fig. 4: Direction of rotation

Fig. 5: Water flush hose connections

2. Installation of the pump

Loading...

Loading...