37

A.0100.301 – IM-FIP/08.00 EN (02/2014)

7.2 Impeller

This guide is designed to help you to identify typical application problems that now and

then occur in flexible impellers during normal use.

Rubber is a “living” material and impellers should be kept in a dark and cool place for

long term storage. The impeller life is strongly reduced by frequent dry running excessive

pressure and/or temperature. It is advised to operate between +10° to +50° C to obtain a

long life.

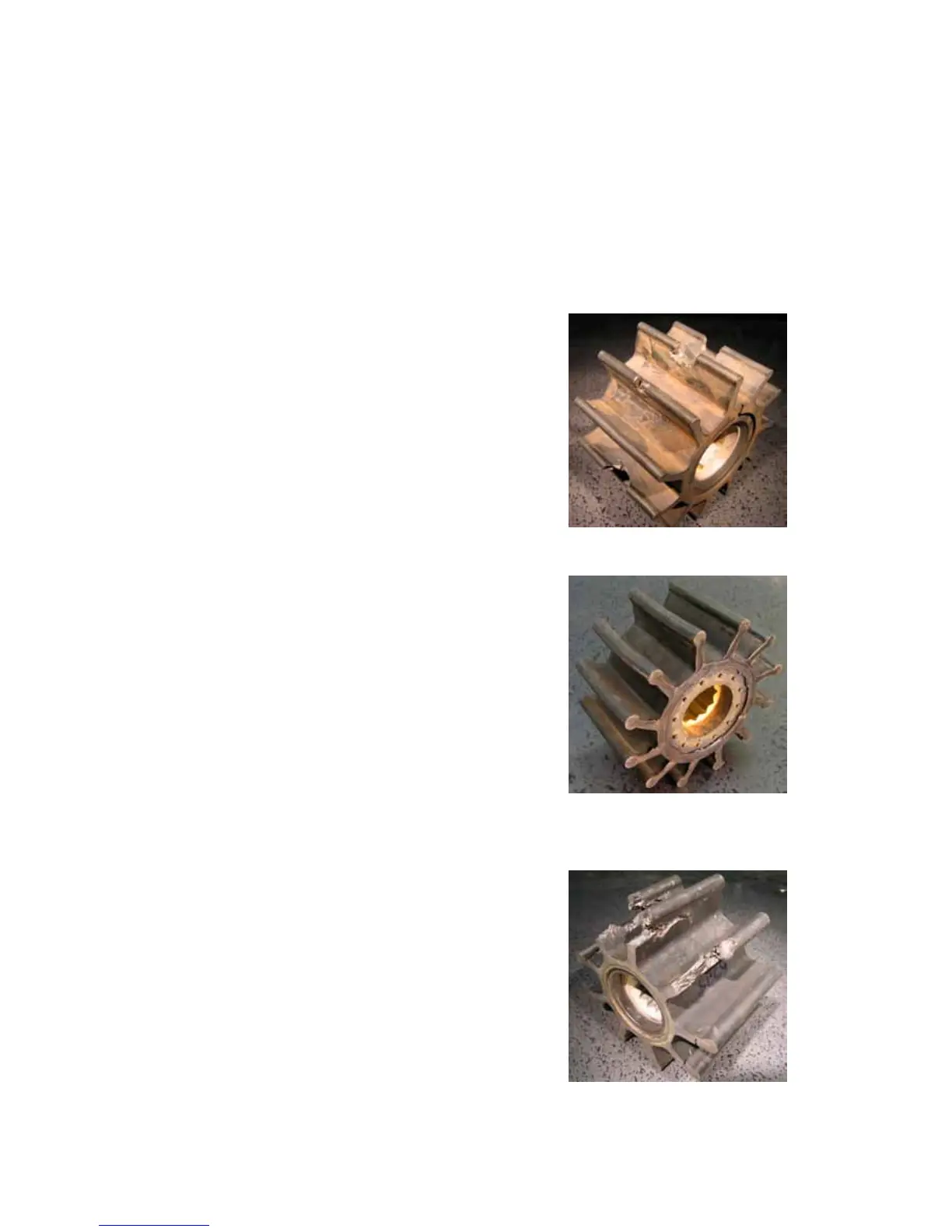

Problem 1

Pieces are missing from vanes/tips, especially in

centre of impeller.

Edges eaten away, hollowed out.

Pitting on ends of impeller.

Causes

Cavitation, i.e. pressure too low at pump inlet, fluid

evaporates locally.

Precautions

Reduce pump speed. Increase inlet pipe diameter.

Reduce inlet pipe length and restrictions.

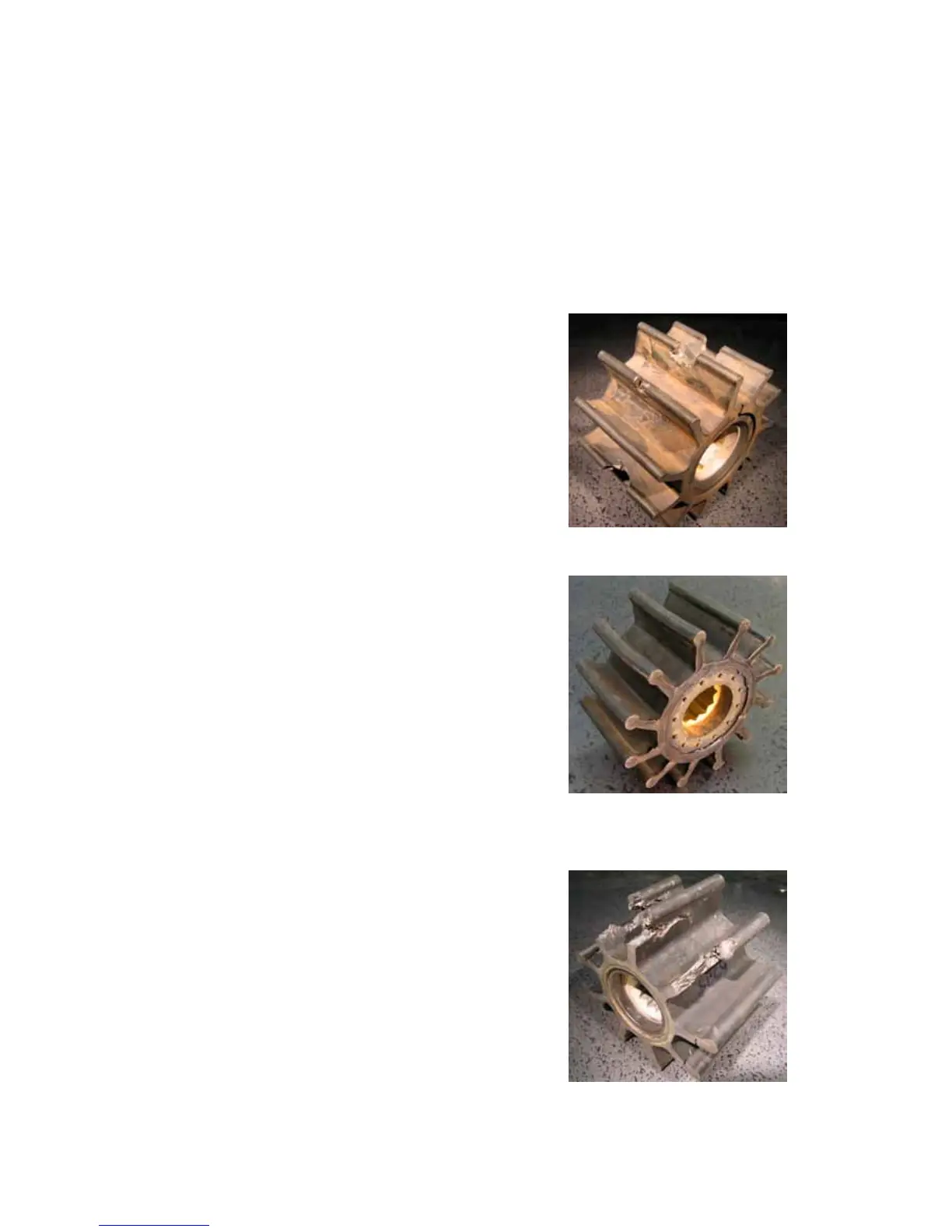

Problem 2

End faces hard, polished, cracked, looks like carbon.

Some or all vanes completely missing in severe

cases.

Causes

Dry running.

Precautions

Do not run more for than 30 seconds without liquid

in the pump. Stop the pump as soon as liquid is

exhausted. Arrange the pipe work to trap liquid in the

pump on the discharge side. Prevents dry running

for several minutes. Install a dry running protection

device, i.e. an electronic pump guard.

Problem 3

Vanes cracked half way up their height. Pieces of

vanes are missing.

Causes

Normal end of useful life. Excessive outlet pressure

reduces impeller life. A crease on trailing side of each

vane can indicate excessive pressure. Liquid temp

above 55° C reduces impeller life.

Precautions

Reduce the discharge pressure by reducing the

pump speed and/or increase the outlet pipe diameter.

Reduce the pipe length and restrictions. Reduce the

liquid temperature.

Loading...

Loading...