10

TROUBLESHOOTING GUIDE

Read and understand safety and operating instructions in this manual

before doing any work on pump!

Only qualified personnel should electrically test pump motor!

Pump does not operate:

1. Check GFCI for proper operation according to GFCI manufacturer’s instru-

tions.

2. Check for plugged impeller. Follow disassembly/assembly instructions

under “Pump Service”, Page 8.

3. Consult dealer/installer or service representative.

Inadequate circulation or jet action:

1. Check for blocked fittings. Block fittings will cause poor flow and poor jet

action.

2. Consult dealer/installer or service representative.

Excessive air in system - pump loses prime:

1. Make sure water level is at least 2” (51mm) above top of jets with system

not operating.

2. Make sure there are no leaks in suction piping.

3. Make sure ther is no vortex (whirlpool) at the suction.

4. Consult dealer/installer or service representative.

Circuit breaker in home panel trips repeatedly:

1. Breaker must be of adequate capacity.

2. For GFCI breaker: test according to GFCI manufacturer’s instructions.

3. Be sure no other lights and appliances are on circuit.

4. Consult dealer/installer or service representative.

Mechanical troubles and noise:

1. If pump suction and discharge piping are not adequately supported, pump

assembly will be strained. See “Installation”, Page 4.

2. Do not mount pump on a wooden platform! Securely mount on a con-

crete platform for quietest performance.

3. Air leak in suction line (bubbles in water returning to pool). Repair leak.

Tighten trap lid.

4. Foreign matter (gravel, metal, etc.) in pump impeller. Disassemble pump,

clean impeller, follow “Pump Serivce” instructions on Page 8 for

reassembly.

5. Cavitation.

Improve suction conditions by increasing pipe size, decreasing number of

fittings. Increase discharge pressure (reduce flow by throttling discharge

gate valve).

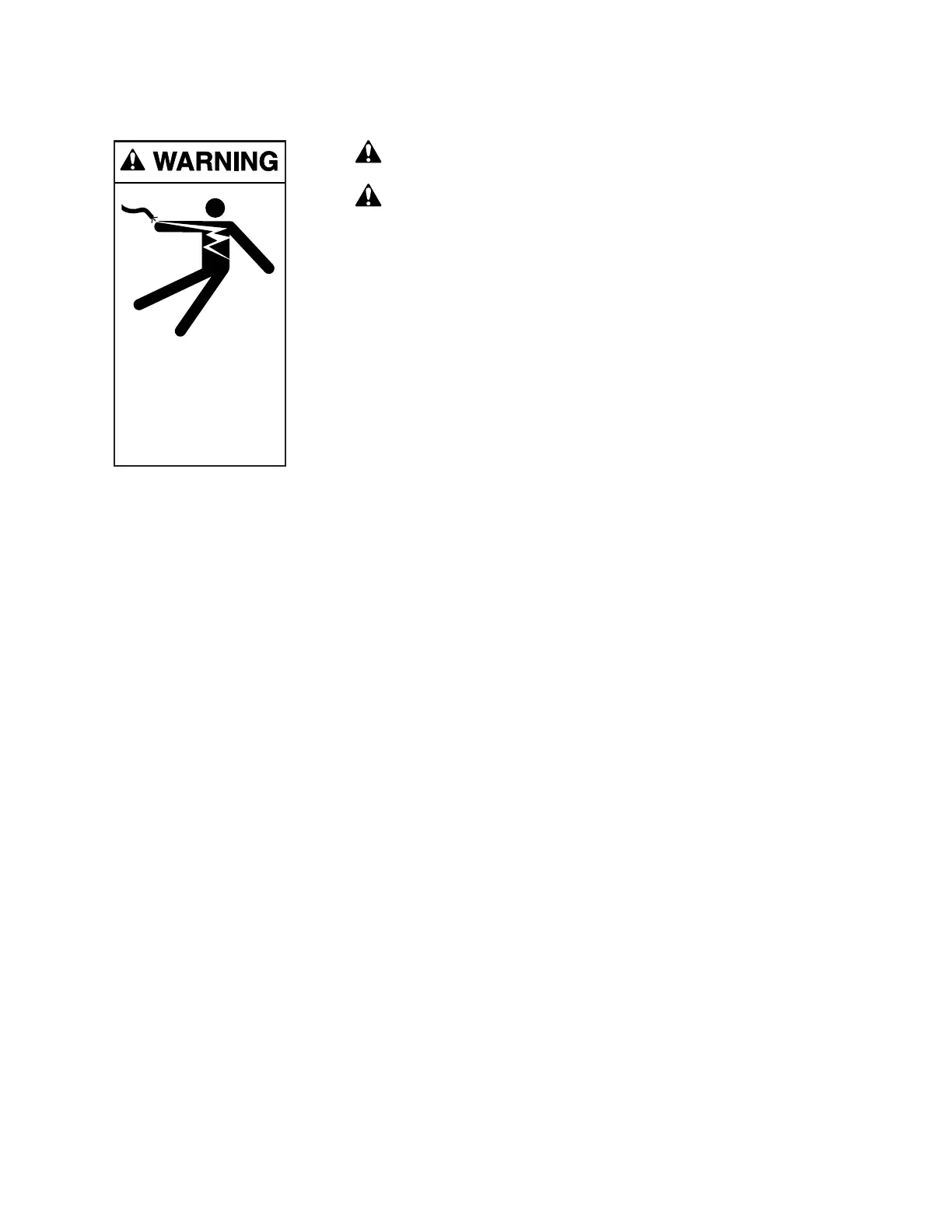

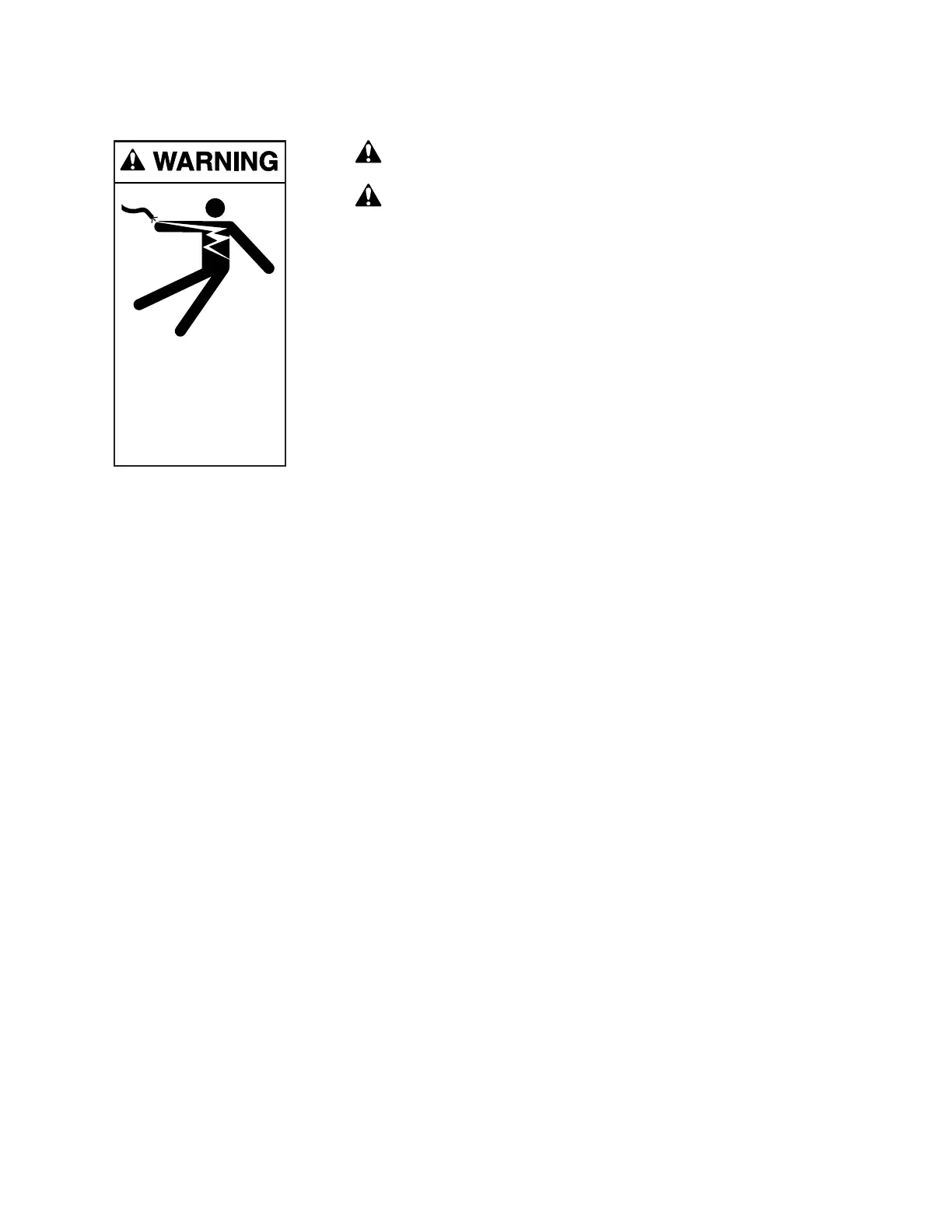

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

Loading...

Loading...