5

Piping:

Use at least 1-1/4" (32mm) IPS PVC. Increase size if a long run is needed.

To avoid strains on the pump, support both suction and discharge pipes inde-

pendently. Place these supports near the pump.

To avoid a strain left by a gap at the last connection, start all piping at the

pump and run pipe away from the pump.

Never use a suction pipe smaller than pump suction connection.

To avoid airlocking, slope suction pipe slightly upward toward the pump.

NOTICE: To prevent flooding when removing pump for service, all flooded

suction systems must have gate valves in suction and discharge pipes.

Fittings:

Fittings restrict flow; for best efficiency use fewest possible fittings.

Avoid fittings which could cause an air trap.

Pool fittings must conform to International Association of Plumbing and

Mechanical Officials (IAPMO) standards.

Use only non-entrapping suction fitting or double suction.

ELECTRICAL

Ground motor before connecting to electrical power supply. Failure to

ground motor can cause severe or fatal electrical shock hazard.

Do not ground to a gas supply line.

To avoid dangerous or fatal electrical shock, turn OFF power to motor

before working on electrical connections.

Ground Fault Circuit Interrupter (GFCI) tripping indicates an electrical

problem. If GFCI trips and will not reset, have a qualified electrician

inspect and repair electrical system.

Exactly match supply voltage to nameplate voltage (115 Volt single

phase only). Incorrect voltage can cause fire or seriously damage motor

and voids warranty. If in doubt consult a licensed electrician.

Voltage

Voltage at motor must be not more than 10% above or below motor name-

plate rated voltage or motor may overheat, causing overload tripping and re-

duced component life. If voltage is less than 90% or more than 110% of rated

voltage when motor is running at full load, consult power company.

Grounding/Bonding

Install, ground, bond and wire motor according to local or National Electrical

Code requirements.

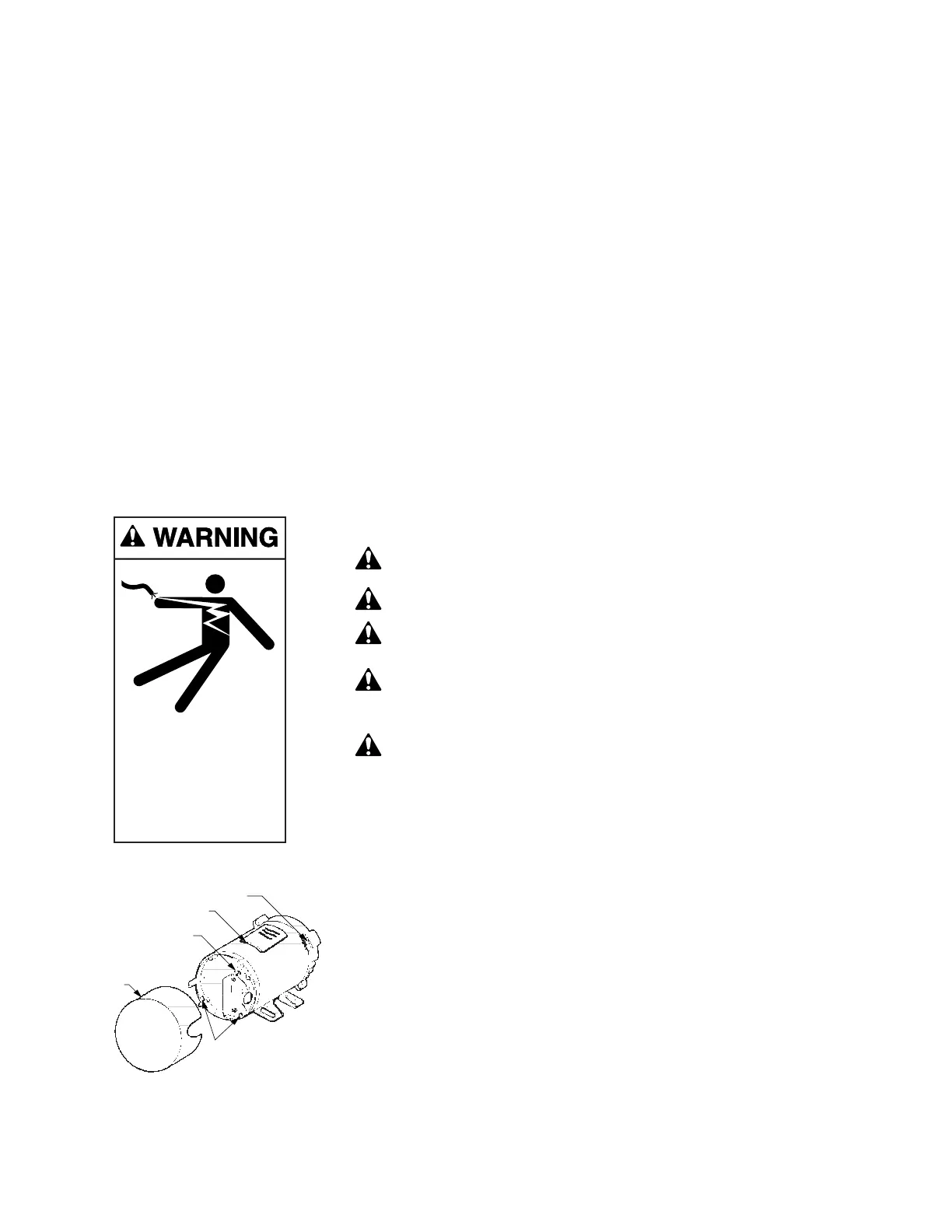

Permanently ground motor. Use green ground terminal provided under motor

canopy or access plate (See Figure 2); use size and type wire required by

code. Connect motor ground terminal to electrical service ground.

Bond motor to pool structure. Use a solid copper conductor, size No. 8 AWG

(8.4 sq. mm) or larger. Run wire from external bonding lug (see Figure 2) to

reinforcing rod or mesh.

Hazardous voltage.

Can shock, burn,

or cause death.

Ground pump before

connecting to

power supply.

Loading...

Loading...