18 | MDP Operation & Maintenance Manual

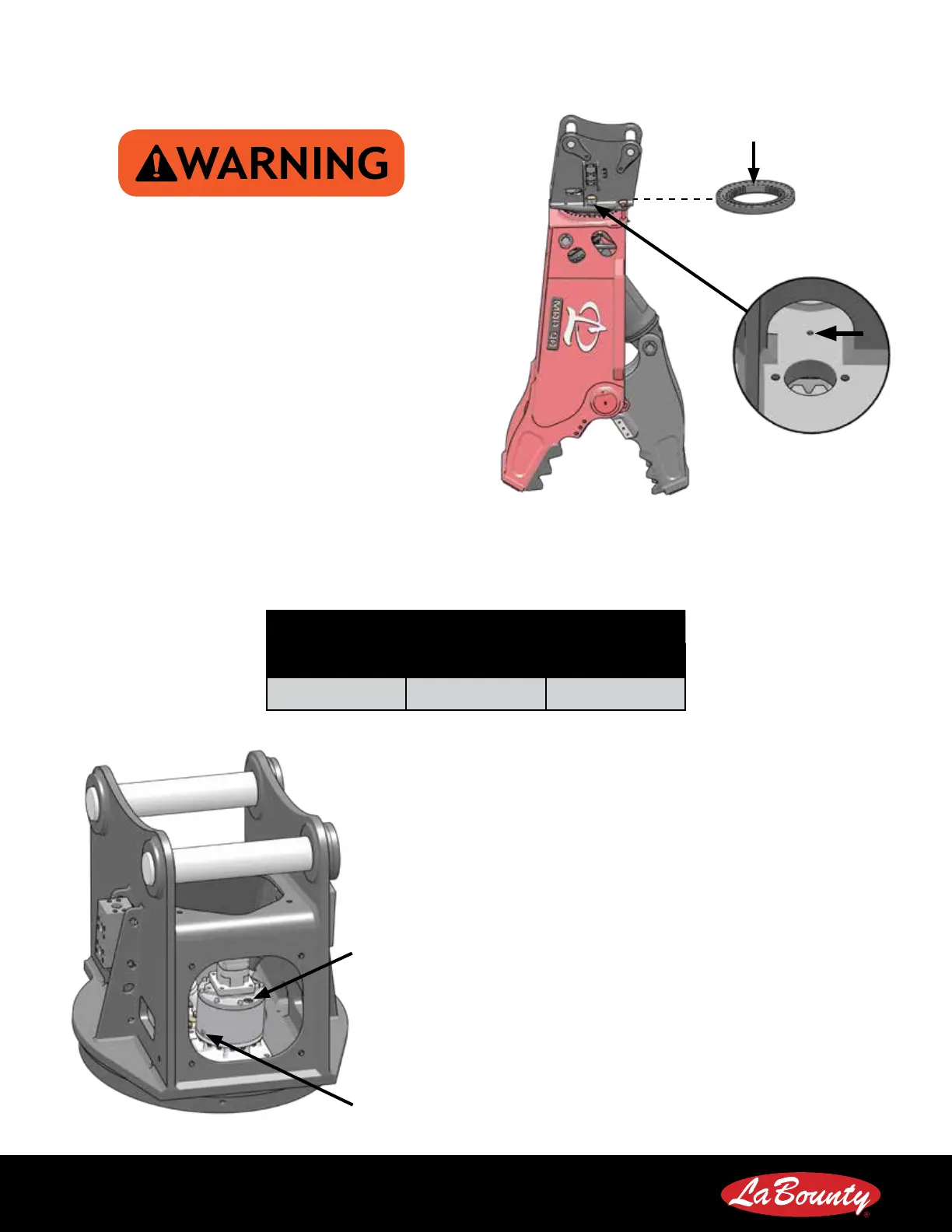

TURNTABLE BEARING LUBRICATION

Stand clear of MDP during rotation.

1. The turntable bearing has 1 to 4 grease ttings,

depending on model type. Use lithium Grade 2 extreme

pressure grease.

Note: For operation below 0° F, use Grade 0 grease.

2. Grease a tting with 4 shots (.2 oz) of grease.

3. Stand clear and rotate the attachment 360°.

4. Grease the same tting with 4 more shots (.2 oz)

of grease, or until grease starts to escape from the

bearing seals.

5. Perform steps 1 through 3 for every grease tting.

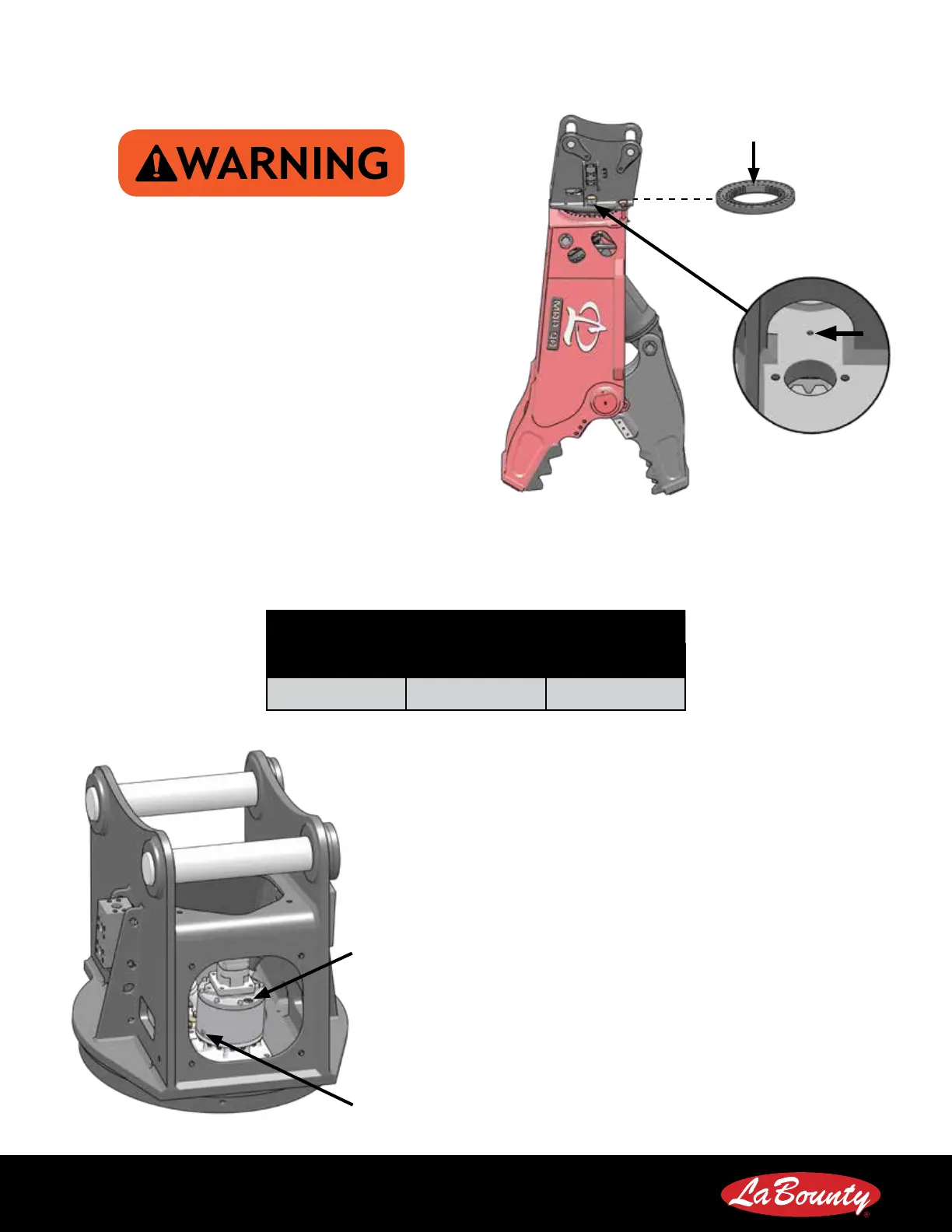

PLANETARY GEARBOX LUBRICATION (SELECT MODELS ONLY)

Some models use a planetary gearbox to rotate the attachment. The gearbox oil must be changed regularly,

based on the Planetary Gearbox Oil Change Schedule.

Planetary Gearbox Oil Change Schedule

500 hours / 1 years

1000 hours / 2 years

Every 1000 hours / 2

years

SAE 80W - 90

Synthetic ISO 150 @

104° F

Synthetic ISO 150 @

104° F

TURNTABLE BEARING

Turntable Lubrication Access

FIGURE 19

OIL FILL PLUG

OIL DRAIN PLUG

Planetary Gearbox Location

FIGURE 20

1. Access the gearbox.

2. Remove the oil ll plug.

3. Remove the oil drain plug. Drain oil into a

container larger than 2 quarts.

Note: The plugs are magnetic and will collect metal

4. Install the oil drain plug.

5. Fill the gearbox with oil, as specied in the parts

manual.

6. Install oil ll plug.

Loading...

Loading...