MDP Operation & Maintenance Manual | 29

TROUBLESHOOTING

FIRST STEPS

• Ensure the hydraulic ow and pressure from the base machine meets specications (see “Hydraulic Circuit

Requirements” on page 8).

• Inspect all hydraulic lines for kinks or damage. Replace any damaged hydraulic lines.

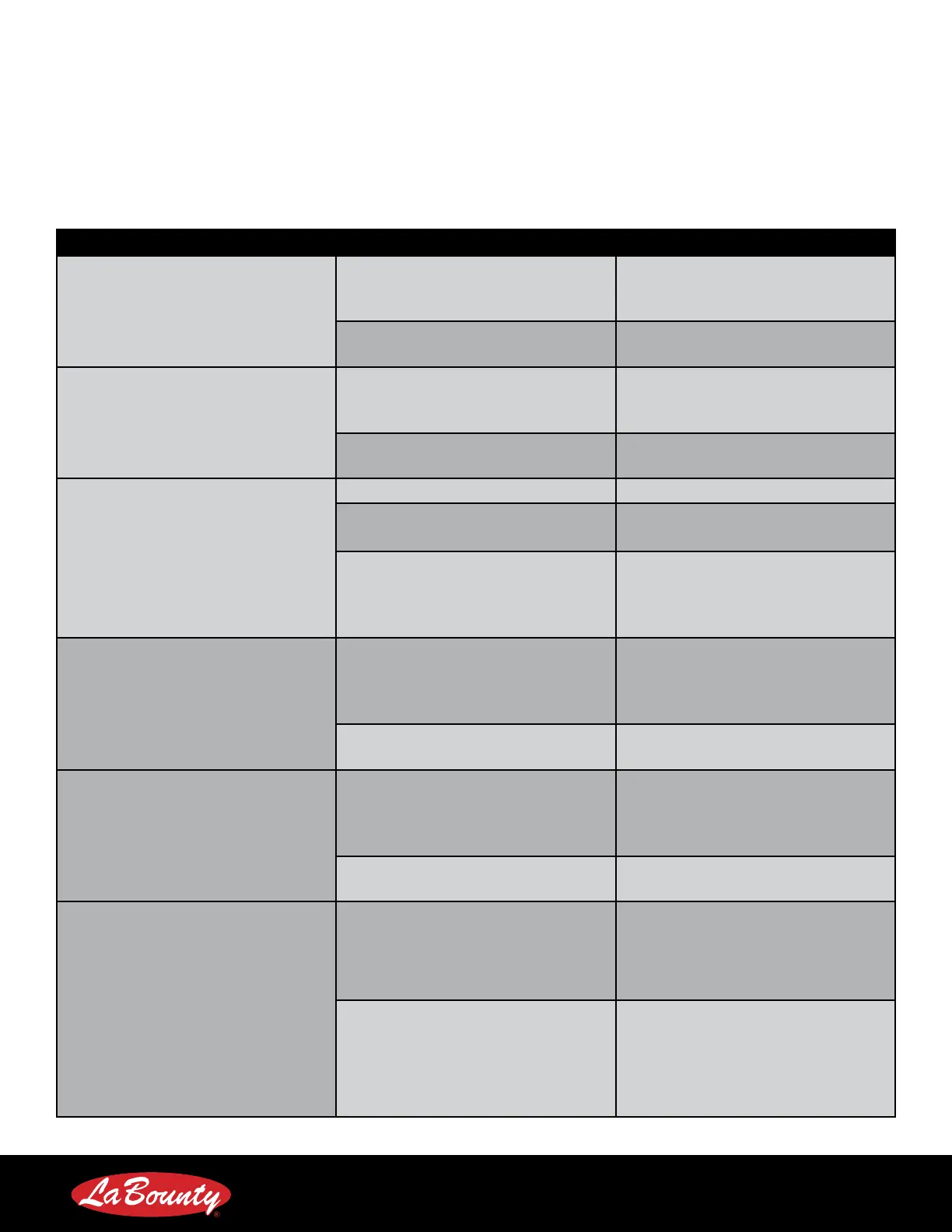

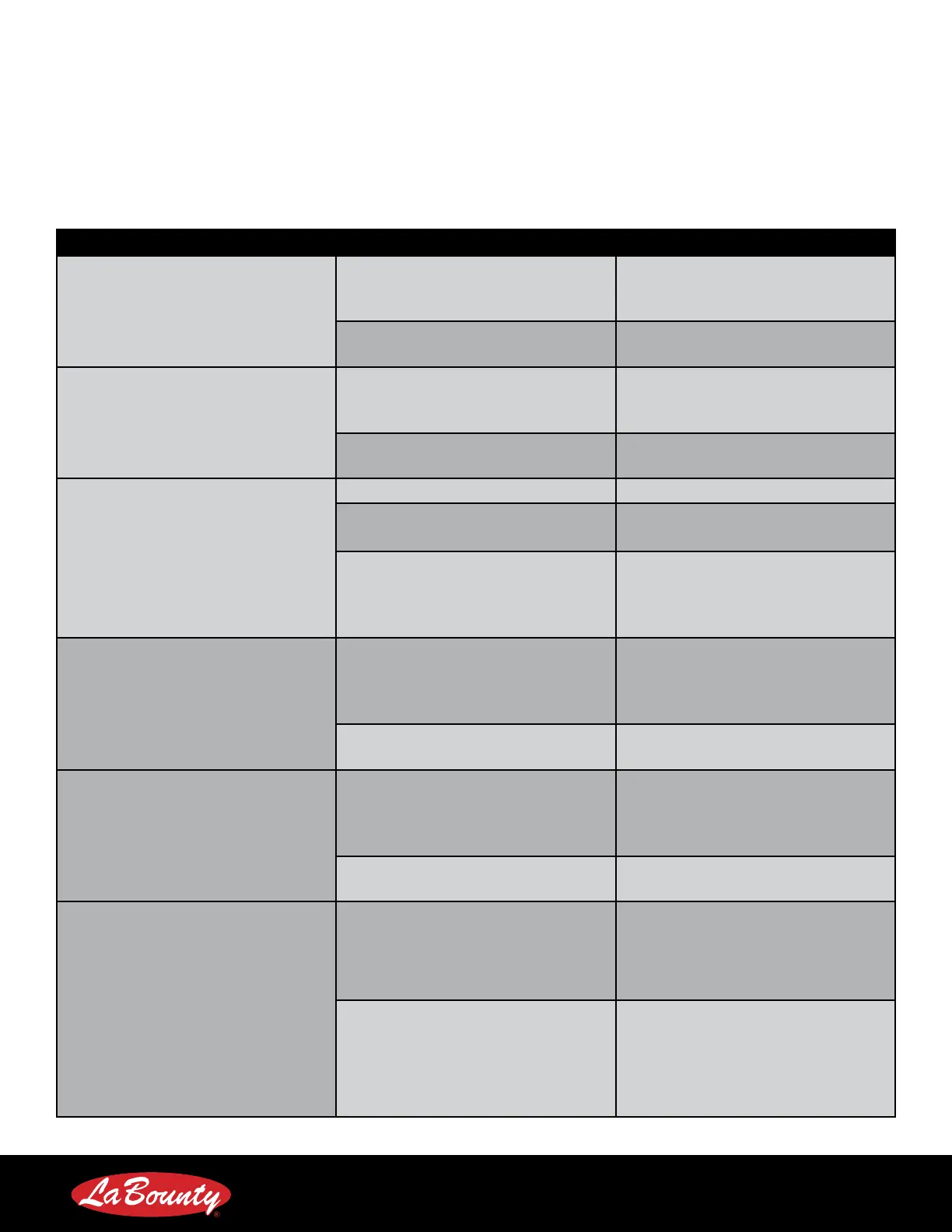

Symptom Cause Remedy

Jaw will not move, moves too fast or

moves too slow.

No hydraulic ow to the MDP or

hydraulic ow is too high.

Check the excavator hydraulic circuit

and ensure the hydraulic lines are not

kinked.

Check speed valve operation.

See “Adjusting the Speed Valve” on

page 23.

Jaws drift open or closed

Base machine valve is open-center or

is faulty.

Use a closed-center spool. Use the

base machine manual to check the

valve.

Speed valve needs adjustment.

See “Adjusting the Speed Valve” on

page 23.

MDP cannot process or hold material

in it’s jaws.

The material is too big. Consult the factory.

Speed valve needs adjustment.

See “Adjusting the Speed Valve” on

page 23.

Back pressure is too high.

Check all hydraulic lines. Ensure they

are not kinked and are the proper size.

Check the base machine circuit for a

restrictor.

MDP will not rotate or rotation is very

slow/fast.

Crossover relief valve is bypassing

oil or the manifold block has internal

leakage.

Replace the crossover valve. Replace

the manifold block on the motor

and check cartridge valve seals for

damage.

The rotation motor/gearbox is worn

out or has a broken output shaft.

Replace or reseal the motor/gearbox.

Jaw rotation drifts left or right.

Control valve ports are open with

spool in the neutral position. There is

leakage in the control valve spool.

Inspect the base machine hydraulic

system.

Crossover relief valve is leaking or is

set too low.

Replace the crossover relief valve.

The jaws don’t shift speed when

closing.

Pilot valve pressure is too high.

Adjust the pilot valve adjustment

counter clockwise in small

increments until issue is corrected

(see “Adjusting the Speed Valve” on

page 23).

Back pressure is too high in the base

machine return line.

Use larger diameter hydraulic lines

to minimize back pressure. Move

the main spool adjustment screw

clockwise in small increments until

the issue is corrected (see “Adjusting

the Speed Valve” on page 23).

Loading...

Loading...