MDP Operation & Maintenance Manual | 19

INSPECT / TORQUE BOLTS

Inspect all bolts for damage. Check the torque of all bolts and replace any bolt that is damaged or has been re-torqued

more than once. Always use replacement bolts of the same size and class as the one removed. Unless otherwise

specied, use class 10.9 metric hex head cap screws, class 10.9 metric at head cap screws and class 12.9 metric

socket head cap screws. When installing new bolts, ensure that the bolt is clean and dry.

Never use an inferior class fastener. Fastener failure

can cause damage, injury or death.

Replace Rotation bolts after 1500 hrs / 2 years. You may

need to rotate MDP to access bolts.

BUILD UP & WEAR PLATES

As the jaws become worn from use, the worn areas will need to be built up to prolong the life of the attachment. Some

areas of the jaw have wear plates that protect commonly worn surfaces and reduces the need to build up and hard-

surface.

Wear safety equipment when welding. This includes

eye protection, hard hat, steel toe shoes, gloves,

hearing protection and respirator. Do all work in a well

ventilated area.

CHECKING AND REPLACING WEAR PLATES

Wear bars are welded into the jaw and must be replaced after they have worn down to 1/4 their original thickness.

Using the MDP parts manual, ensure you have ordered the proper wear plate kits.

Installing Wear Bars

1. Preheat the area around the wear bar to 250° to 300° F.

2. Remove the worn wear bar.

3. Fit the new wear bar into the receptacle.

4. Weld the wear bar into place.

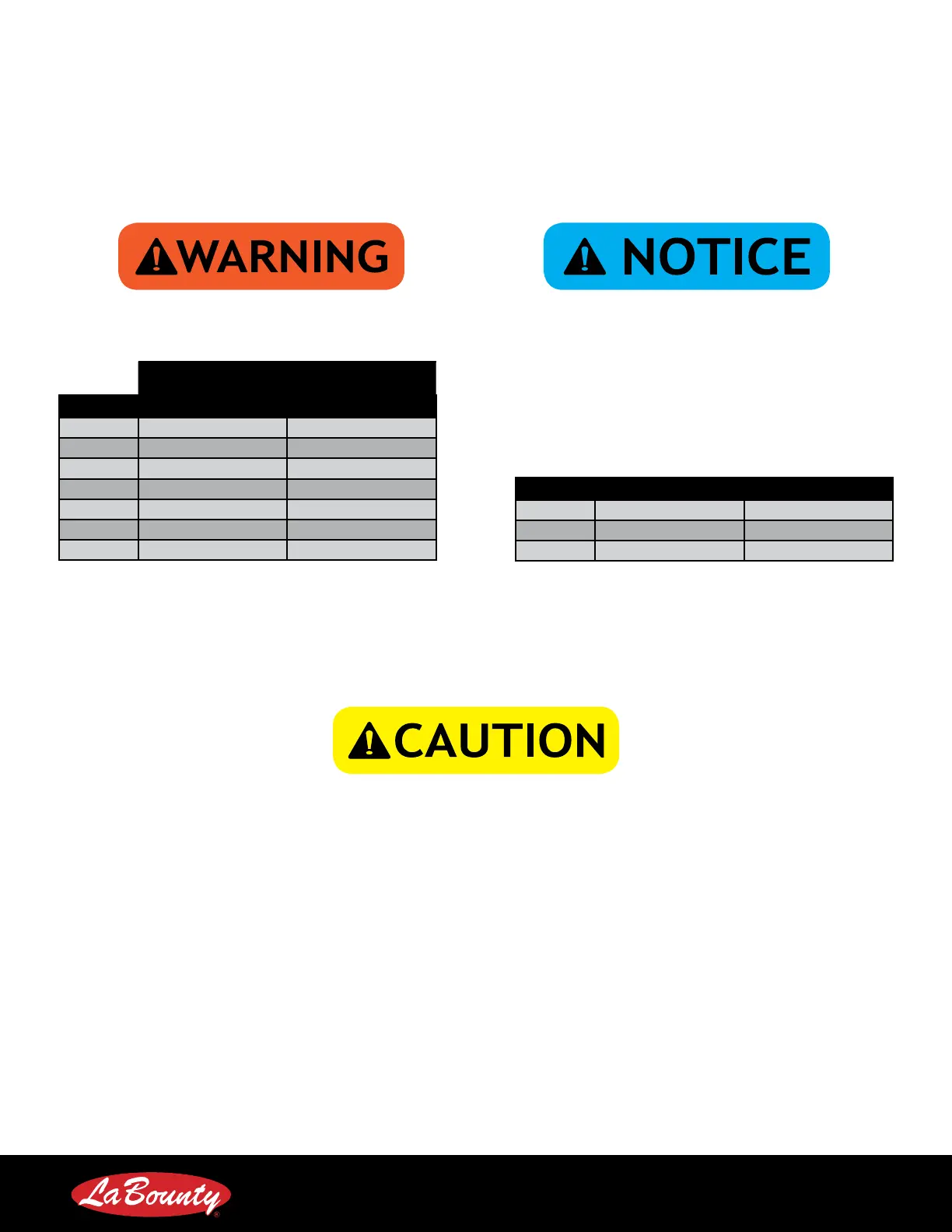

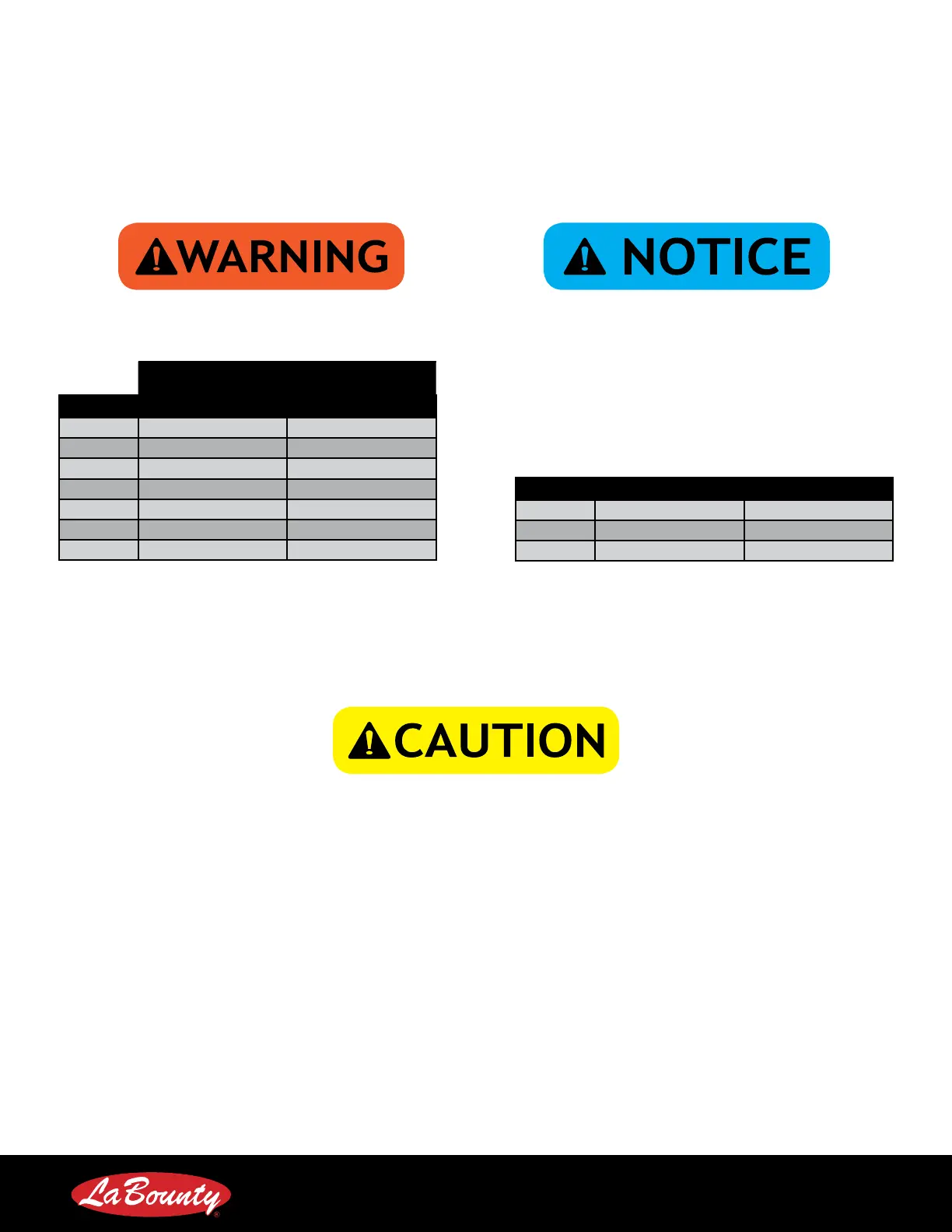

General Fastener Torque

FIGURE 21

Torque

Size

Class 10.9 Class 12.9

M10

41 Ft. Lbs. (55 Nm) 49 Ft. Lbs. (67 Nm)

M12

71 Ft. Lbs. (96 Nm) 85 Ft. Lbs. (116 Nm)

M14

112 Ft. Lbs. (152 Nm) 136 Ft. Lbs. (185 Nm)

M16

173 Ft. Lbs. (235 Nm) 207 Ft. Lbs. (281 Nm)

M20

335 Ft. Lbs. (454 Nm) 403 Ft. Lbs. (547 Nm)

M24

579 Ft. Lbs. (785 Nm) 693 Ft. Lbs. (939 Nm)

M30

1164 Ft. Lbs. (1579 Nm) 1391 Ft. Lbs. (1887 Nm)

Turntable & Rotation Head Fastener Torque

FIGURE 22

Size

Class Torque

M20

10.9 435 Ft. Lbs. (590 Nm)

M24

10.9 752 Ft. Lbs. (1020 Nm)

M30

10.9 1511 Ft. Lbs. (2049 Nm)

Loading...

Loading...