20 | MDP Operation & Maintenance Manual

5. Cover the weld with a heat blanket and allow it to cool slowly.

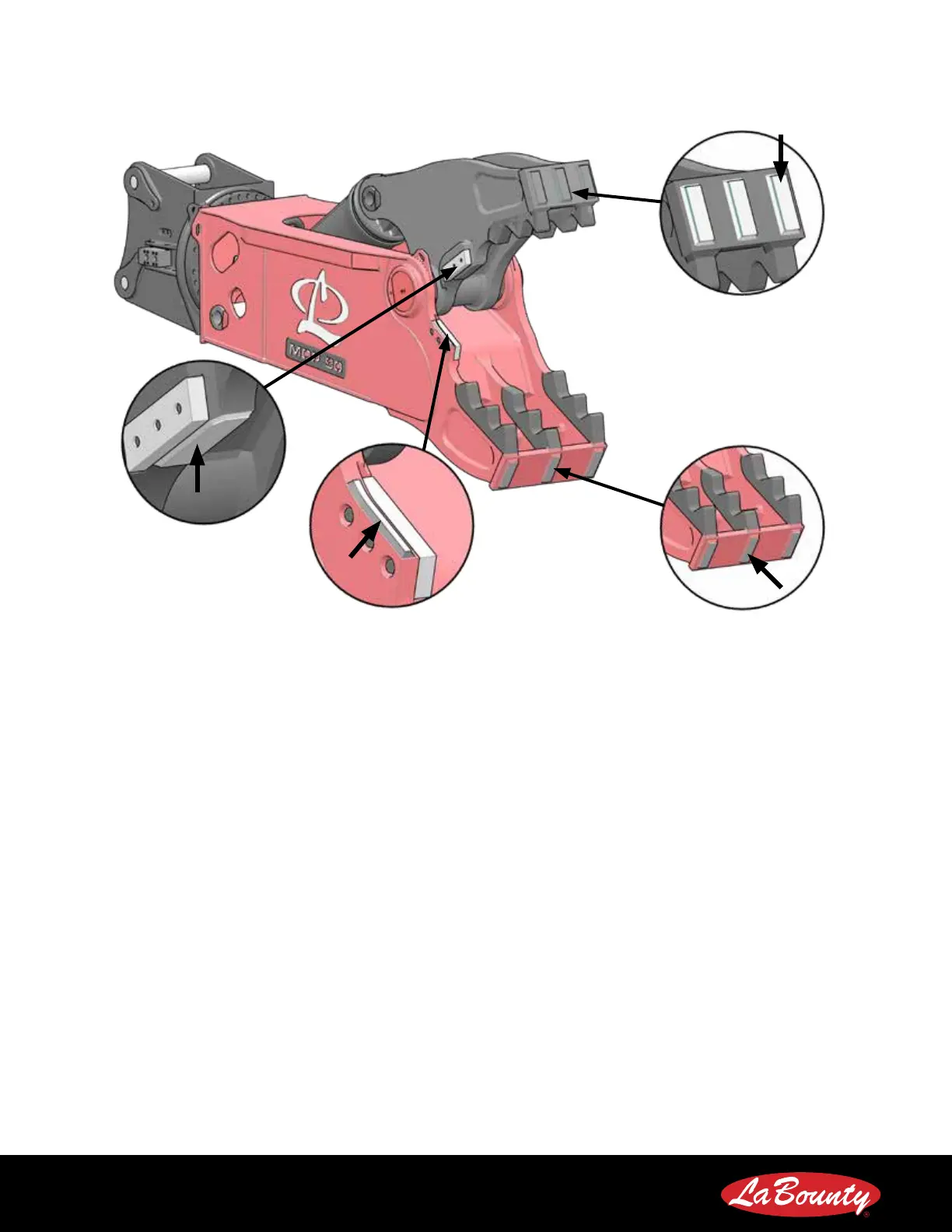

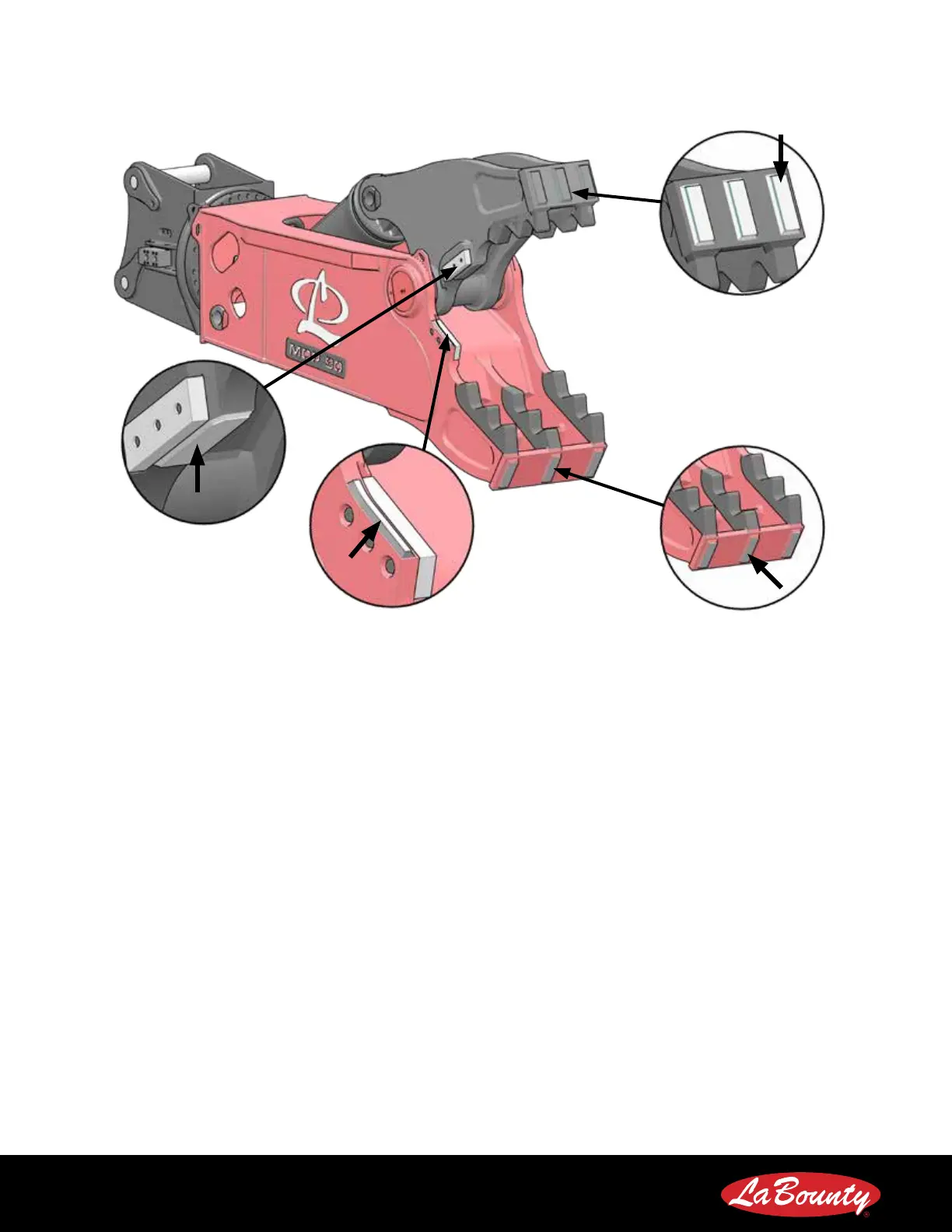

Wear Plate Locations

FIGURE 23

Jaw Teeth Build Up

1. Obtain the proper tooth build up template. Refer to the parts manual for template part numbers.

2. Throughly clean the area to be built up. Grind o any existing hard-surface material.

3. Preheat the area to 200° F (93.3° C) to remove moisture.

4. Preheat the area to be build up to 300° - 400° F (149° - . 204° C)

5. Use the tooth template to determine how much build up is required.

6. Using AWS E7018 welding rod, make hard surface beads, as shown in Figure 24.

7. Relieve stress and remove slag after each pass by peening vigorously with an air operated slag peener.

8. Repeat steps 6 and 7 until the tooth prole matches the build up template.

9. Grind edges square to match the template.

10. Using AWS E7018, place underlayment passes, as shown in Figure 24.

11. Apply a bead of Amalloy 814H rod on top of each of the underlayment beads.

12. Relieve stress after each pass by peening vigorously with an air operated slag peener.

13. Taper the end of each hard-surface bead by grinding.

Note: Do NOT undercut the weld.

14. When grinding is complete, peen the area until it is shiny or until the peener cannot dent the weld.

Note: About 5-10 minutes.

15. Cover the welded area with a heat blanket and allow to cool slowly.

Loading...

Loading...