MC521 PRO Control Box

03.23.2017

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204090 REV D 5

Copyright 2017 Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

• Repeat for second door operator: CONNECT yellow jumper wires installed on the single/dual motor harness as

follows:

a. INSTALL stripped end of rst jumper wire (from posion 3 of the 8-pin connector on operator harness) into

terminal 9 of control box connector TB3.

b. INSTALL stripped end of second jumper wire (from posion 5 of the 8-pin connector on operator harness)

into terminal 10 of control box connector TB3.

• Repeat for second door operator: SET the auxiliary cam for approximately 3° acvaon (toward breakout direc-

on), and ADJUST cam as necessary to trip the corresponding microswitch prior to acvaon of the breakout

switch.

Note: In a dual-door applicaon, the breakout switches of each operator need to be wired in series to ensure

that the control box will not open the doors if either breakout status switch is acvated.

• IF applicaon is a pair of doors, PERFORM the following:

a. REPEAT the previous two steps for the second door operator.

b. CONNECT stripped end of one yellow jumper wire from each operator to terminals 9 and 10 of control box

connector TB3.

• Using a wire nut, CONNECT remaining wire from rst operator to remaining wire on second operator.

• VERIFY breakout status/breakout cam is properly set as follows:

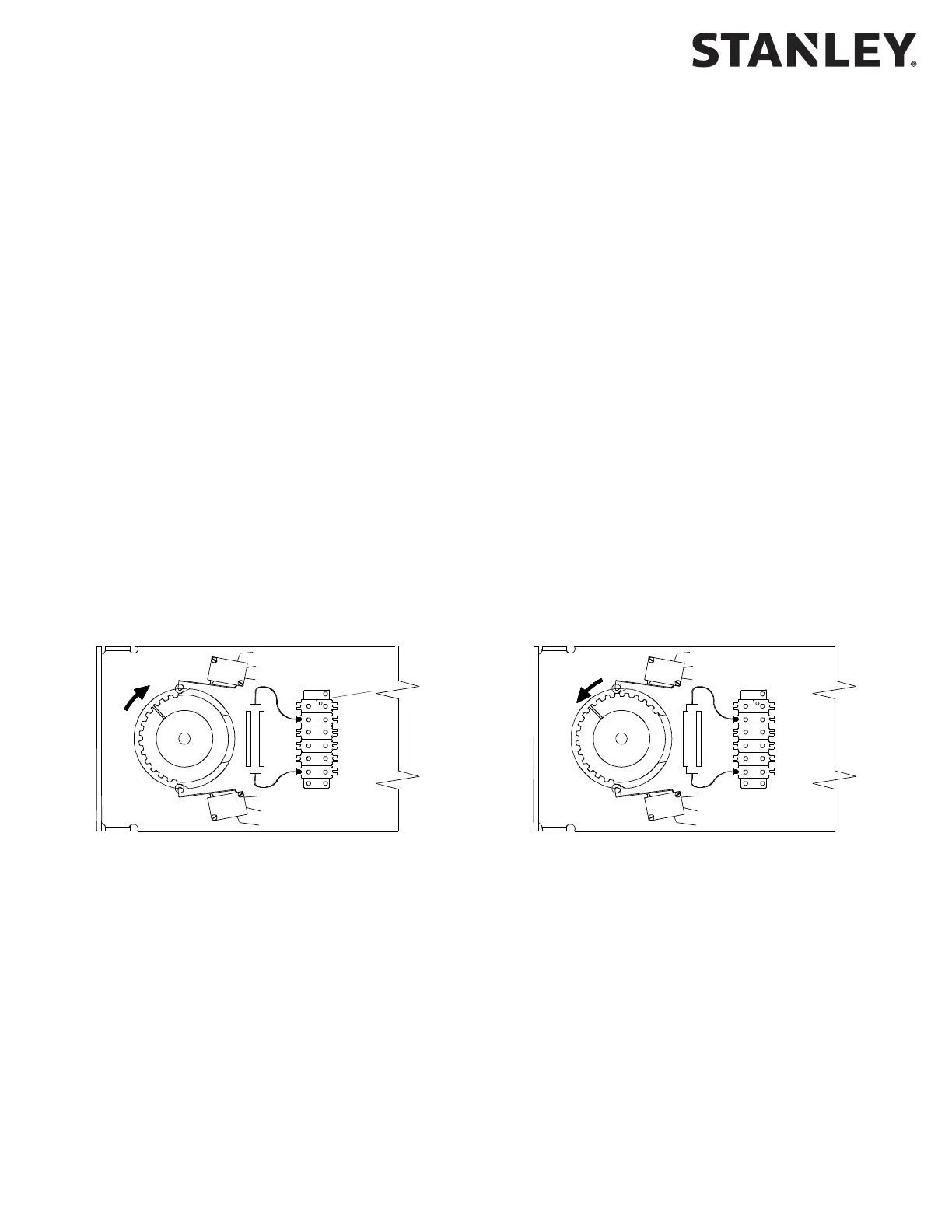

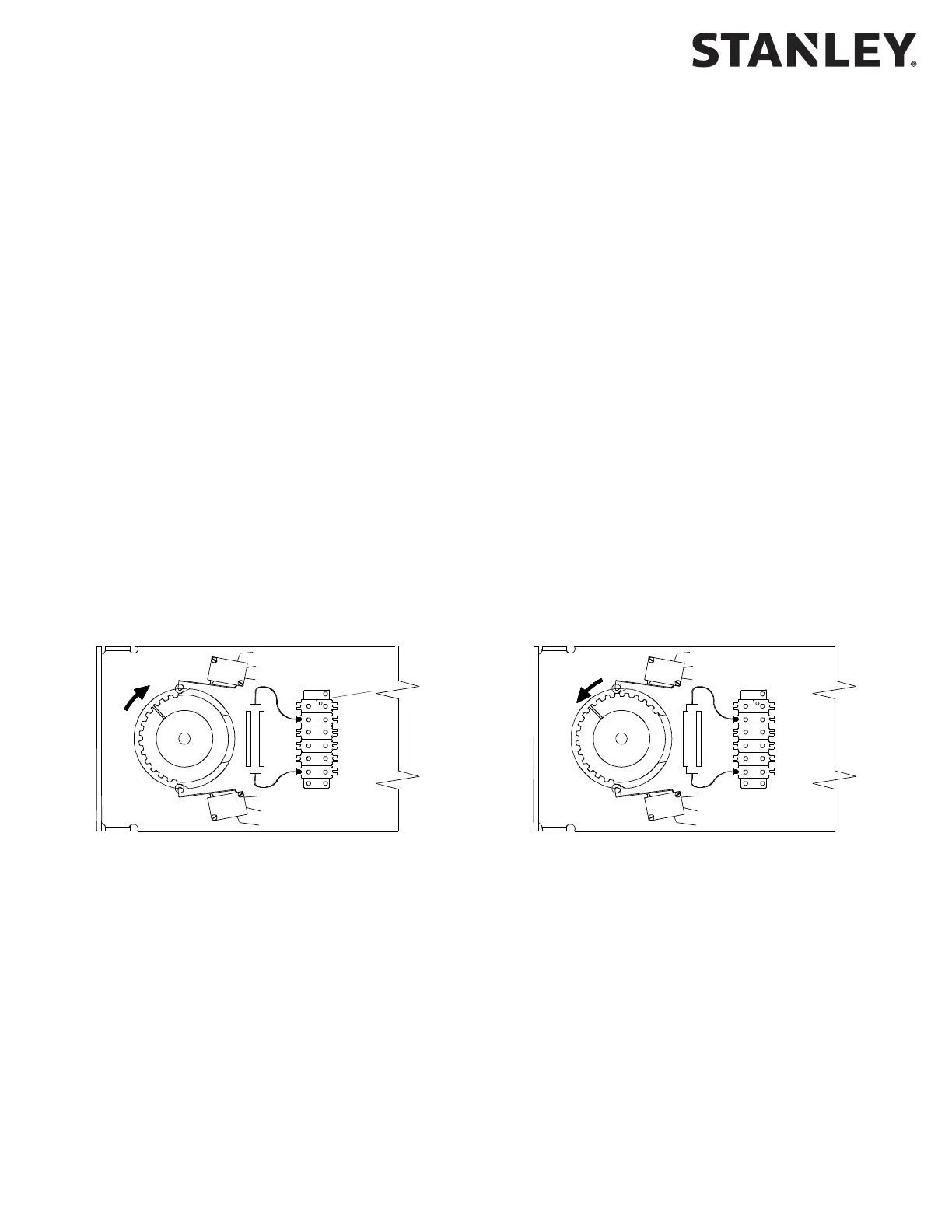

a. Refer to Figure I, and visually INSPECT cams for proper seng.

b. UNPLUG TB3 from control box.

Note: When checking breakout status switch connuity, the switch is rst checked with the door closed,

then again with the door in the breakout (negave 3°) posion. In a dual-door applicaon, both doors can

be tested at the same me in the closed posion. However, the doors must be tested individually when

checking switch connuity with the doors in the breakout (negave 3°) posion.

c. ENSURE door is in the closed posion.

d. Using a mulmeter, CHECK connuity between TB3 terminals 9 and 10, and ENSURE there is connuity.

e. PUSH door in the breakout direcon, and HOLD door at approximately the negave 3° posion.

f. Using a mulmeter, CHECK connuity between TB3 terminals 9 and 10, and ENSURE there is an open circuit.

g. RELEASE door.

h. PLUG TB3 into control box.

TOP CAM = AUX SWITCH

CENTER CAM = EMERGENCY BREAKOUT SWITCH

BOTTOM CAM = CLOSE CHECK SWITCH

EMERGENCY SWITCH

N.C.: RED

N.O.: YELLOW

COM.: BLACK

OPEN CHECK SWITCH

N.O.: BROWN

COM.: ORANGE

CLOSE CHECK SWITCH

N.C.: WHITE

COM.: BLUE

TOP CAM = AUX SWITCH

CENTER CAM = EMERGENCY BREAKOUT SWITCH

BOTTOM CAM = CLOSE CHECK SWITCH

RH SHOWN RH SHOWN

Figure 1. Breakout Status/Breakout Cam Settings (Magic-Swing Operators)

N.O.

N.C.

COM

N.O.

N.C.

N.C.

COM

N.O.

N.C.

N.O.

Loading...

Loading...