CL42T(V4.1) Closed-Loop Stepper Driver

4

Notes: (1) Shielding control signal wires is suggested;

(2)

To avoid/reduce interference, don’t tie control signal cables and power wires together;

(3)

Brake output need to connect a relay and diode

3.2

P2 - Encoder Signals Input Connector

The P2 connector in Figure 2 is for encoder signals connection. Refer to the following table for details.

Drive Pin Name

Description

EB+

Encoder B+ input connection

EB-

Encoder B- input connection

EA+

Encoder A+ input connection

EA-

Encoder A- input connection

VCC

Encoder +5V voltage output connection

EGND

Power ground connection

3.3

P3 - Motor Connector

PIN

Details

A+ Connect to motor A+ wire

A- Connect to motor A- wire

B+ Connect to motor B+ wire

B- Connect to motor B- wire

3.4

P4 - Power Connector

Pin

Details

GND Connect to power supply ground connection.

+VDC Connect to power supply positive connection. Suggest 24-48VDC power supply voltage

Warning: Don’t plug/unplug P3 or P4 connector to avoid drive damage or injury while powered on.

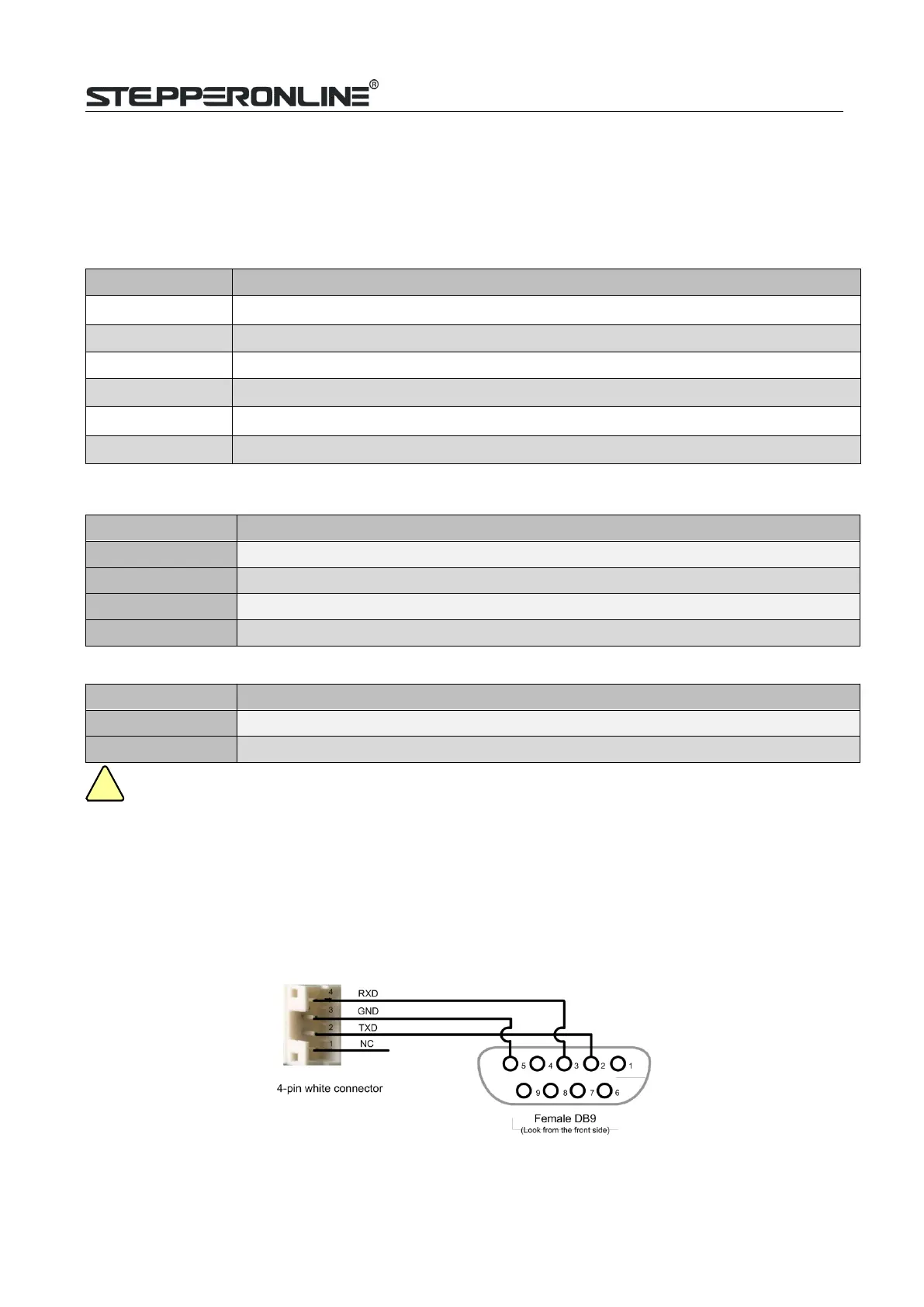

3.5

P5 – Debug Port

The P5 connector in Figure 2 is a RS232 communication port for PC connection. Refer to the following pin

definitions.CL42T has a tuning port with RS232 to modify the drive parameters; it is just used to modify

parameter, not for equipment control because neither precision nor stability is sufficient.

The interface definition is as follows:

Loading...

Loading...