CL42T(V4.1) Closed-Loop Stepper Driver

6

Higher supply voltage can increase motor torque at higher speeds (>300 RPM), thus helpful for avoiding losing

steps.However, higher voltage may cause bigger motor vibration at lower speed, and it may also cause over-

voltage protection or even drive damage.

5.

Switch Configurations

5.1

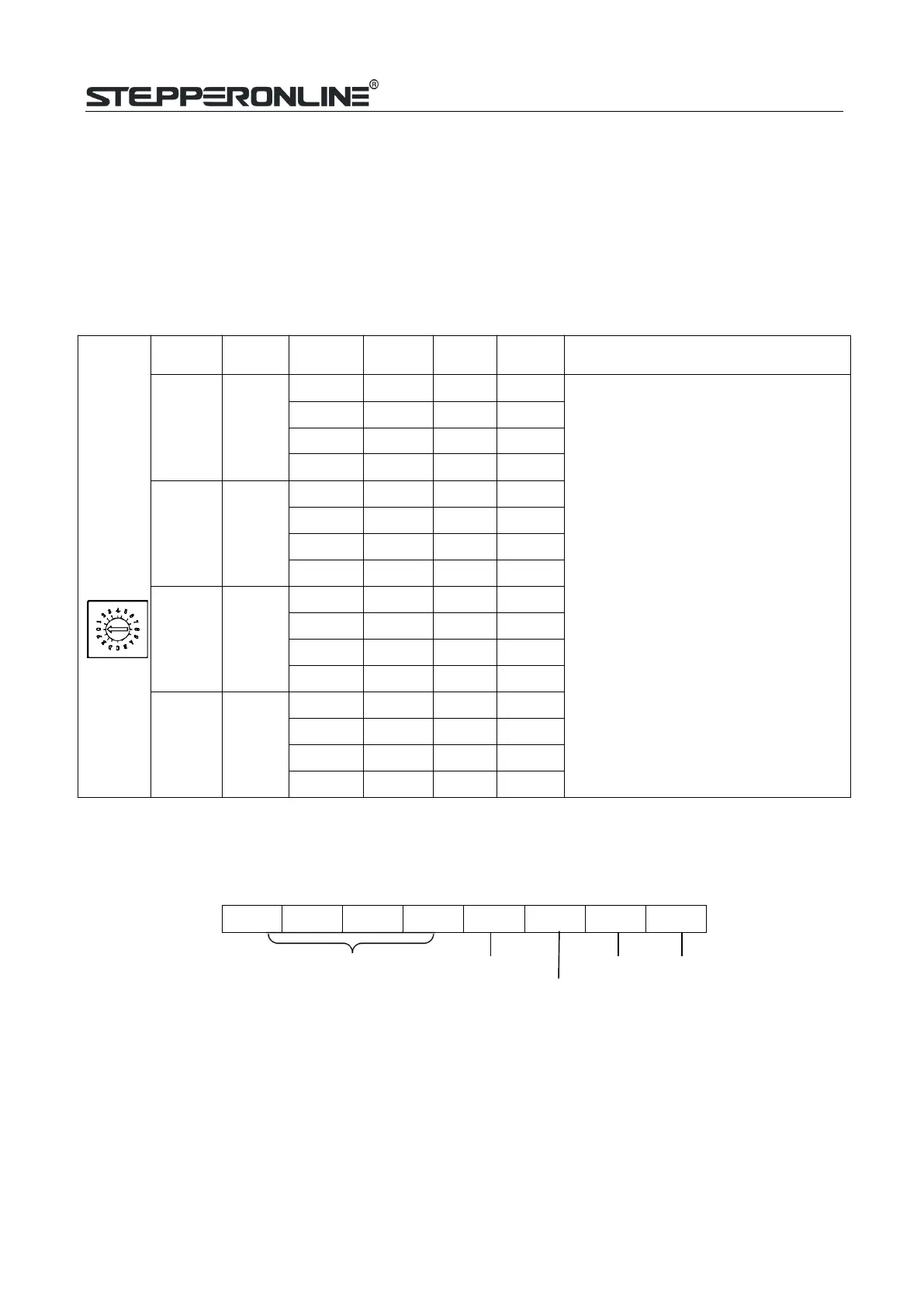

S1 - Rotating Switch Configurations

This rotating switch is used to set the peak current of the drive and motion gain, from the motor phase

current andapplication requirements.

Peak

Current

RMS

Current

Code

Velocity

loop Ki

loop Kp

Velocity

loop Kp

Remark

0.8 0.6

0 (factory)

0 25 25

1)

Velocity loop Ki Indicates the stop

time and position accuracy, “0”

indicates the stop time is long, but the

position error issmaller.“16” means

the stop time is short,but the position

error is slightly larger.

2)

Position loop Kp and velocity loop Kp

is a pair of composite parameters that

representrigidity. “25” and “25”composite

parametersindicate the rigidity is weak,

“100” and “5”composite parameters

indicate the rigidity is strong. Sometimes

if the motor

will rotate after stopping, it can increase

thevalue of position loop Kp, but if the

value is too large, the motor will have

noise.

3)

Usually keep factory settings

1

0 50 15

2

16 25 25

3

16 50 15

1.4 1

4

0 25 25

5

0 50 15

6

16 25 25

7

16 50 15

2.1 1.5

8

0 25 25

9

0 50 15

A

16 25 25

B

16 50 15

2.8 2

C

0 25 25

D

0 50 15

E

16 25 25

F

16 50 15

5.2

S2 - DIP Switch Configurations

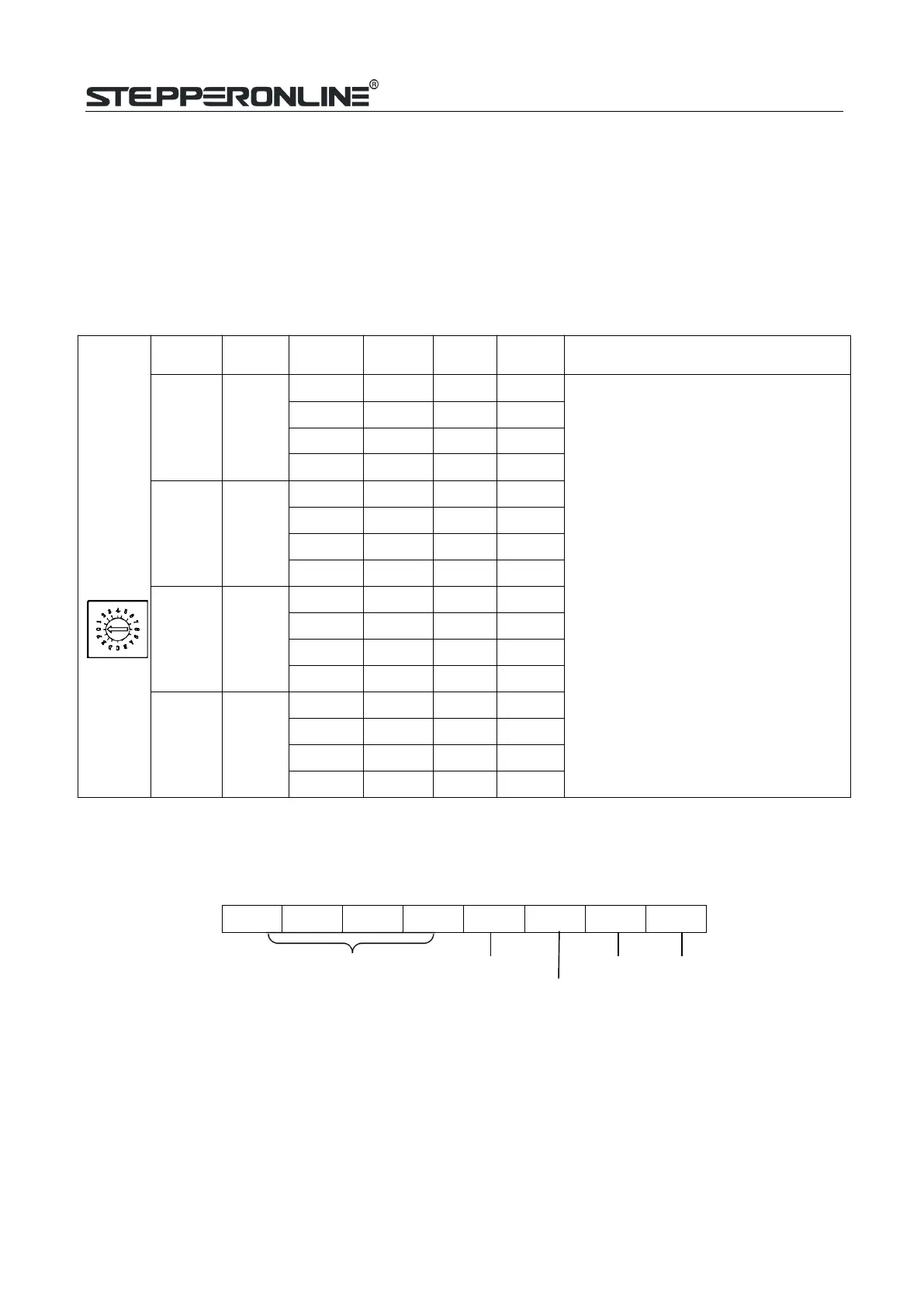

The 8-bit is located on the side (DIP switch S2 in Figure 2) and used to configure settings of micro step

resolution,output current, and motor standstill current as shown below

SW1 SW2 SW3 SW4 SW5

SW6

SW7 SW8

Microstep

Rotation

Pulse mode

Pulse filter time

Control mode

Figure 3: DIP switches

Loading...

Loading...