CL42T(V4.1) Closed-Loop Stepper Driver

7

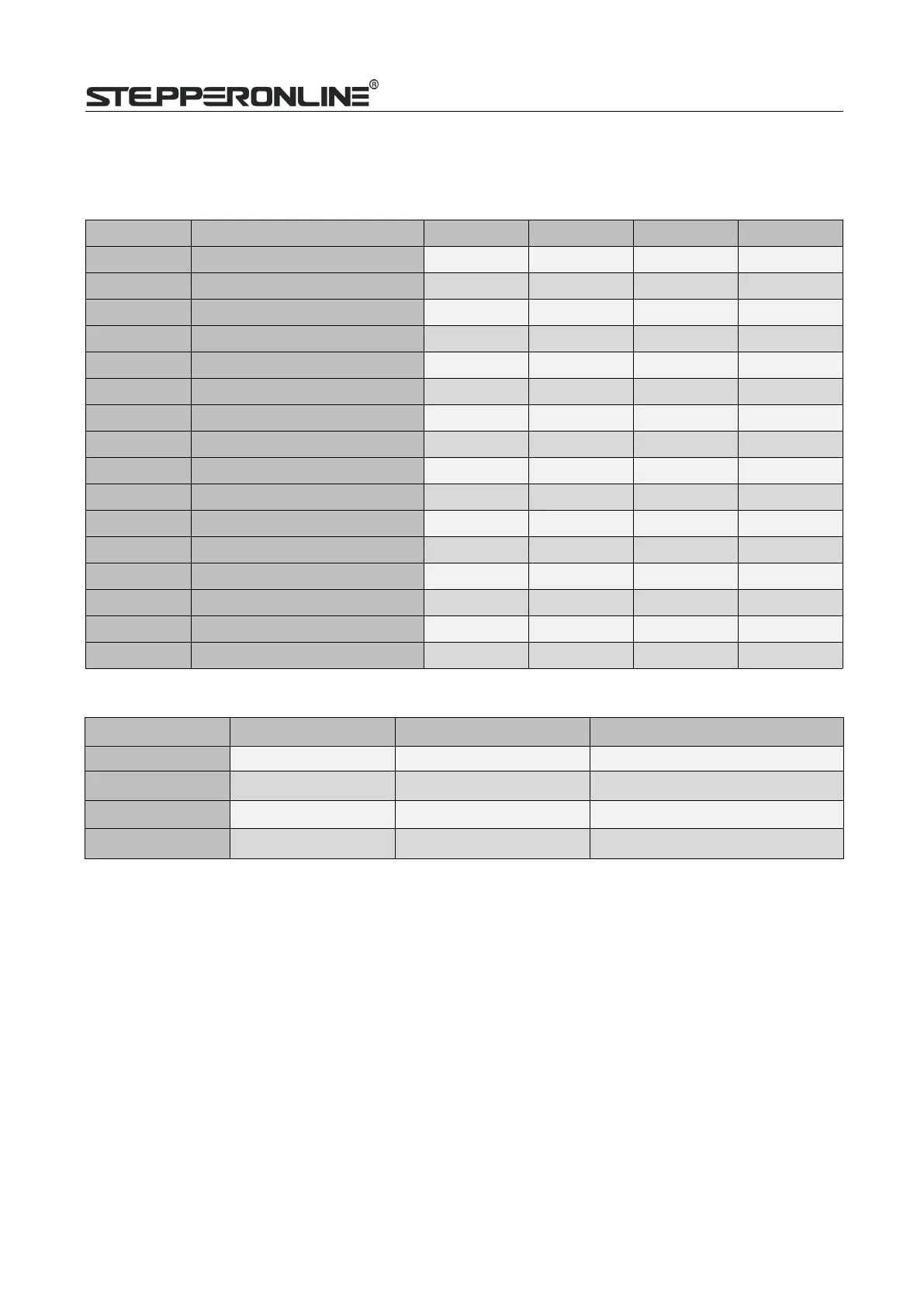

5.2.1

Micro Step (SW1-SW4)

Each CL42T(V4.1) has 16 microstep settings which can be configured through DIP switches SW1, SW2, SW3

and SW4.See the following table for detail.

Micro step Pulses/Rev. (for 1.8°motor)

SW1 SW2 SW3 SW4

1

200

on on on on

4

800

off on on on

8

1600

on off on on

16

3200

off off on on

32

6400

on on off on

64

12800

off on off on

128

25600

on off off on

256

51200

off off off on

5

1000

on on on off

10

2000

off on on off

20

4000

on off on off

25

5000

off off on off

40

8000

on on off off

50

10000

off on off off

100

20000

on off off off

200

40000

off off off off

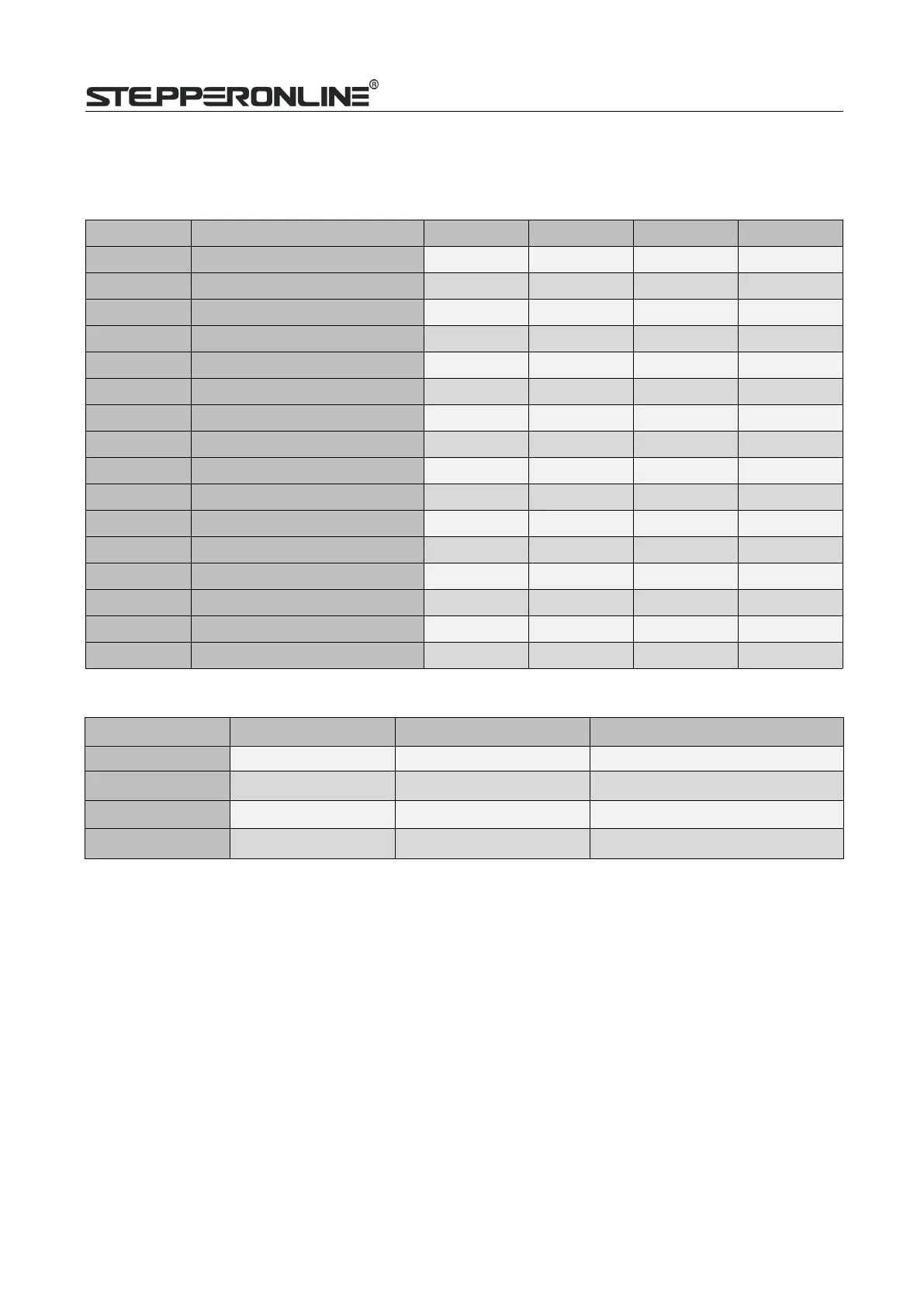

5.2.2

Mode Setting (SW5 - SW8)

Function

ON OFF

SW5

Rotation Direction CW (clockwise) CCW (counterclockwise)

SW6

Control Mode Open loop control Closed loop control

SW7

Pulse Mode CW/CCW (double pulse)

PUL/DIR (single pulse)

SW8

Pulse Filter Time Yes (10ms) No (1.5ms)

CL42T(V4.1) has an advanced feature called Pulse Filter Time to make the input pulse from pulse generator

(controller,PLC, etc.) S-curve acceleration, to improve motion smoothness and high-speed start frequency in

manycircumstances.

The Filter Time value must be set to the same for each CL42T(V4.1) in multi-axis applications

5.3

S3 - Selector Switch Configurations

The 1-bit selector is located on the top (S3 in figure 2), used to configure the voltage of control signals. For the

safety of optically coupled, the factory setting is 24V, which no need to connect 2K resistors, making it easier to

use. Whenthe voltage of the control signal is 5V, the S3 must be set to 5V, otherwise, the motor won't work.

Loading...

Loading...