3. Remove the paper lter (19:B). Make sure

that no dirt gets into the carburettor. Clean

the air lter housing.

4. Clean the paper lter by tapping it gently

against a at surface. If the lter is very dirty,

replace it.

5. Assemble the lter by performing the above

instructions in reverse order.

Compressed air or petroleum-based solvents

such as kerosene must not be used for cleaning

the paper lter insert. This will damage the lter.

The paper lter insert must not be oiled.

9.10.2 Cleaning / Replacement - mod.: [STI-

GA] (18)

Remove/install the air lters as follows:

1. Carefully clean around the air lter cover.

2. Remove the air lter cover (18:A) by remo-

ving the two clamps.

3. Dismantle the lter assembly (18:D; 18:E).

The prelter is placed over the air lter. Make

sure that no dirt gets into the carburettor.

Clean the air lter housing.

4. Clean the paper lter by tapping it gently

against a at surface. If the lter is very dirty,

replace it.

5. Clean the pre-lter. If the lter is very dirty,

replace it.

6. Assemble the lter by performing the above

instructions in reverse order.

9.10.3 Replace the spark plug

For the frequency of this intervention

see chapter 13.

Before removing the spark plug, clean around its

mounting.

For the type of spark plug and relative spark gap,

please refer to “0 TECHNICAL DATA TABLE”.

9.10.4 Cleaning the air intake.

For the frequency of this intervention

see chapter 13.

See gure (18:B; 19:B; 19A:B).

The engine is air-cooled.

A blocked cooling system can damage the engine.

More meticulous cleaning of the cooling system

should be carried out during each basic service.

9.11 LUBRICATION (20)

For the frequency of this intervention

see chapter 13.

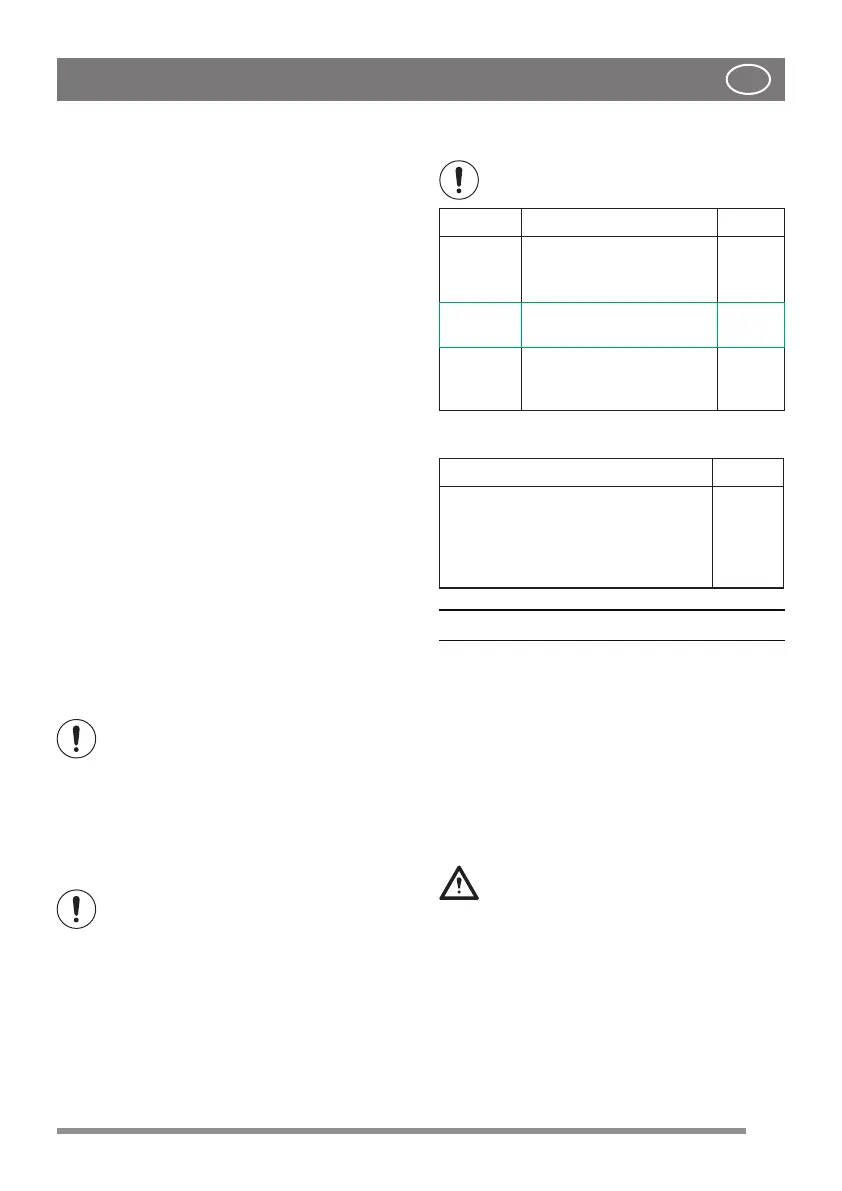

Object Action Fig.

Wheel

bearings

3 grease nipples

Use a grease gun lled

with universal grease.

(20:A)

Steering

spring

Use multipurpose grease (20:B)

Gear

cable

Lubricate the cable ends

with oil when each control

is activated.

(20:C)

9.12 FUSES (20:D)

Fault Fuse

In the event of electrical faults, check/

replace the fuse.

If the problem persists, contact an

authorized servicing centre to get the

relative repairs carried out.

(20:D)

10 ASSISTANCE AND REPAIRS

This manual provides all the necessary infor-

mation to run the machine and for correct basic

maintenance operations which can be performed

by the user.

Any regulations and maintenance operations not

described herein must be carried out by your De-

aler or Authorized Service Centre, which have the

necessary knowledge and equipment to ensure

that the work is carried out correctly, maintaining

the correct degree of safety and the original opera-

ting conditions of the machine.

Before performing any servicing opera-

tions:

a. Place the machine on a at surface.

b. Activate the parking brake (11:B)

c. Stop the engine.

d. Remove the key from the ignition.

Authorized service workshops carry out guaran-

teed repairs and maintenance.

Always use genuine spare parts.

EN

ENGLISH

(Translation of the Original Instructions)

21

Loading...

Loading...