36 Series 4144 Components FC, FS, KM

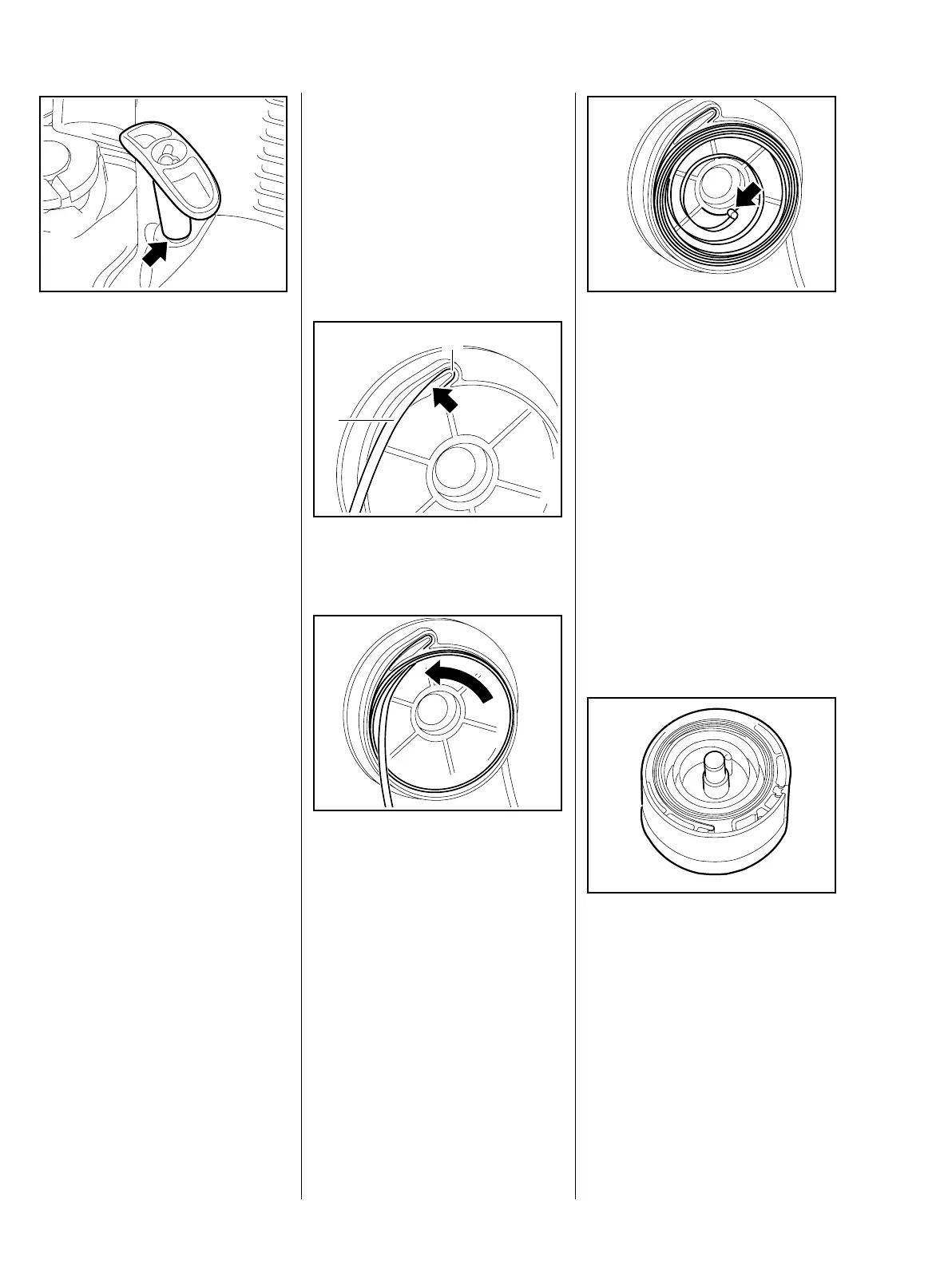

The rewind spring is correctly

tensioned when the starter grip sits

firmly in the rope guide bushing

(arrow) without drooping to one

side. If this is not the case, tension

the spring by one additional turn.

When the starter rope is fully

extended, it must still be possible to

rotate the rope rotor as follows

before maximum spring tension is

reached.

Standard version

= 1 full turn

ErgoStart version

= 1 – 2 full turns

If this is not the case, reduce spring

tension since there is otherwise a

risk of breakage.

To reduce spring tension:

Pull the rope out, hold the rope rotor

steady and take off one turn of the

rope.

– Install the rewind starter,

b 6.2

– Tightening torques, b 3.4

6.7 Replacing the

Rewind Spring

– Troubleshooting, b 4.2

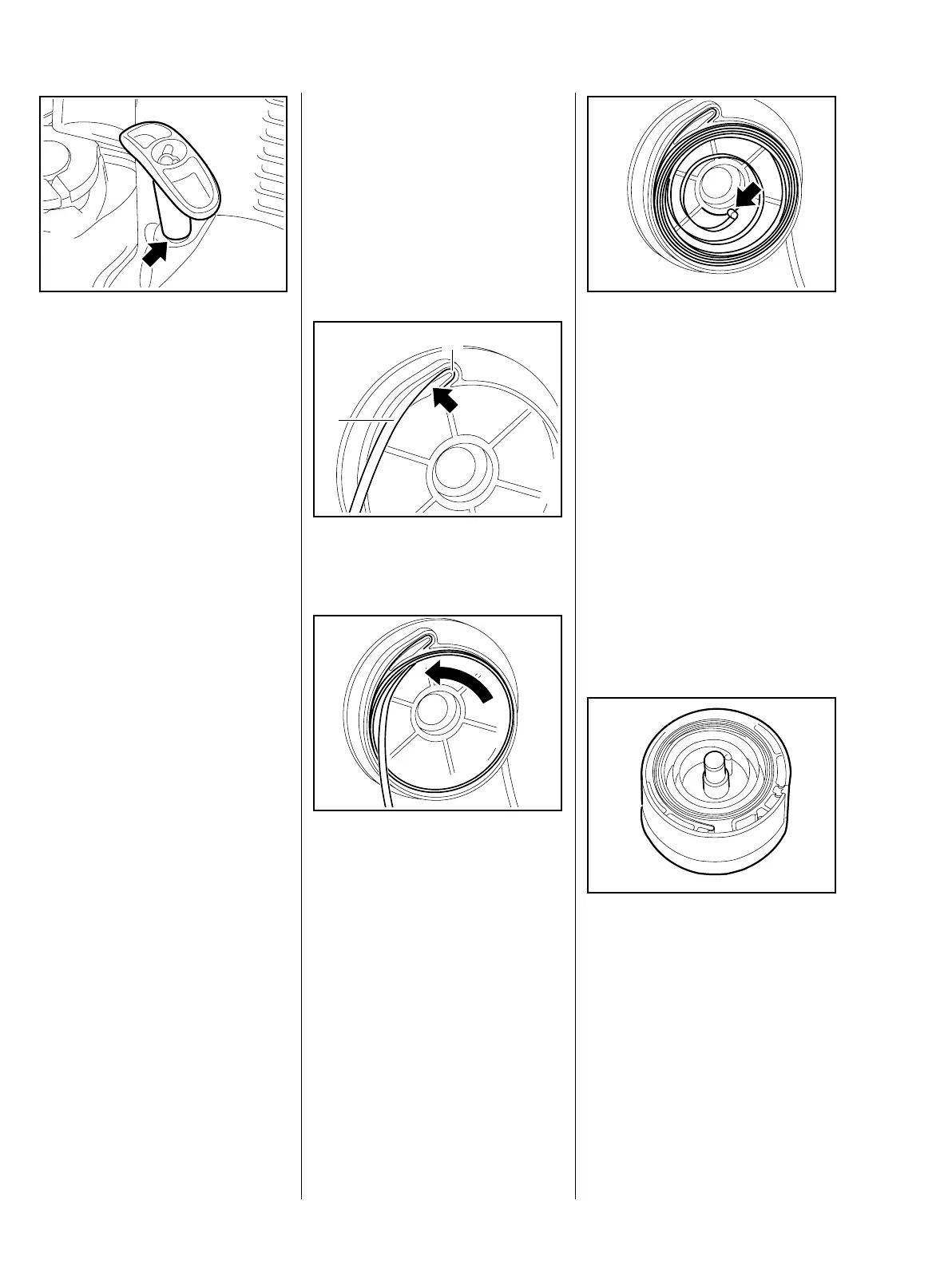

The rewind spring is installed in the

rope rotor.

545RA123 TG

A replacement spring is supplied

ready to install with a new rope

rotor.

If the rewind spring has popped out,

refit it in the rope rotor as follows:

Wear a face shield and work gloves.

– Remove the rope rotor, b 6.4

: Engage anchor loop (1) in its seat

(arrow) in the rope rotor (2).

: Fit the rewind in the

counterclockwise direction,

holding the windings steady to

prevent them popping out.

545RA279 TG

2

1

545RA109 TG

– Secure the spring so that it

cannot pop out.

: If necessary, line up the inner

spring loop (arrow) so that it is

against the edge of the rope rotor.

– Remove the rope rotor, b 6.4

– Tension the rewind spring, b 6.6

– Reassemble all other parts in the

reverse sequence.

– Tightening torques, b 3.4

6.8 ErgoStart

The Ergostart is installed in the rope

rotor, b 6.4

If the ErgoStart spring has popped

out, install a new rope rotor.

A new rope rotor comes with the

rewind spring and ErgoStart spring

preassembled.

545RA109 TG

545RA288 TG

Loading...

Loading...