39MS 440, MS 440 C

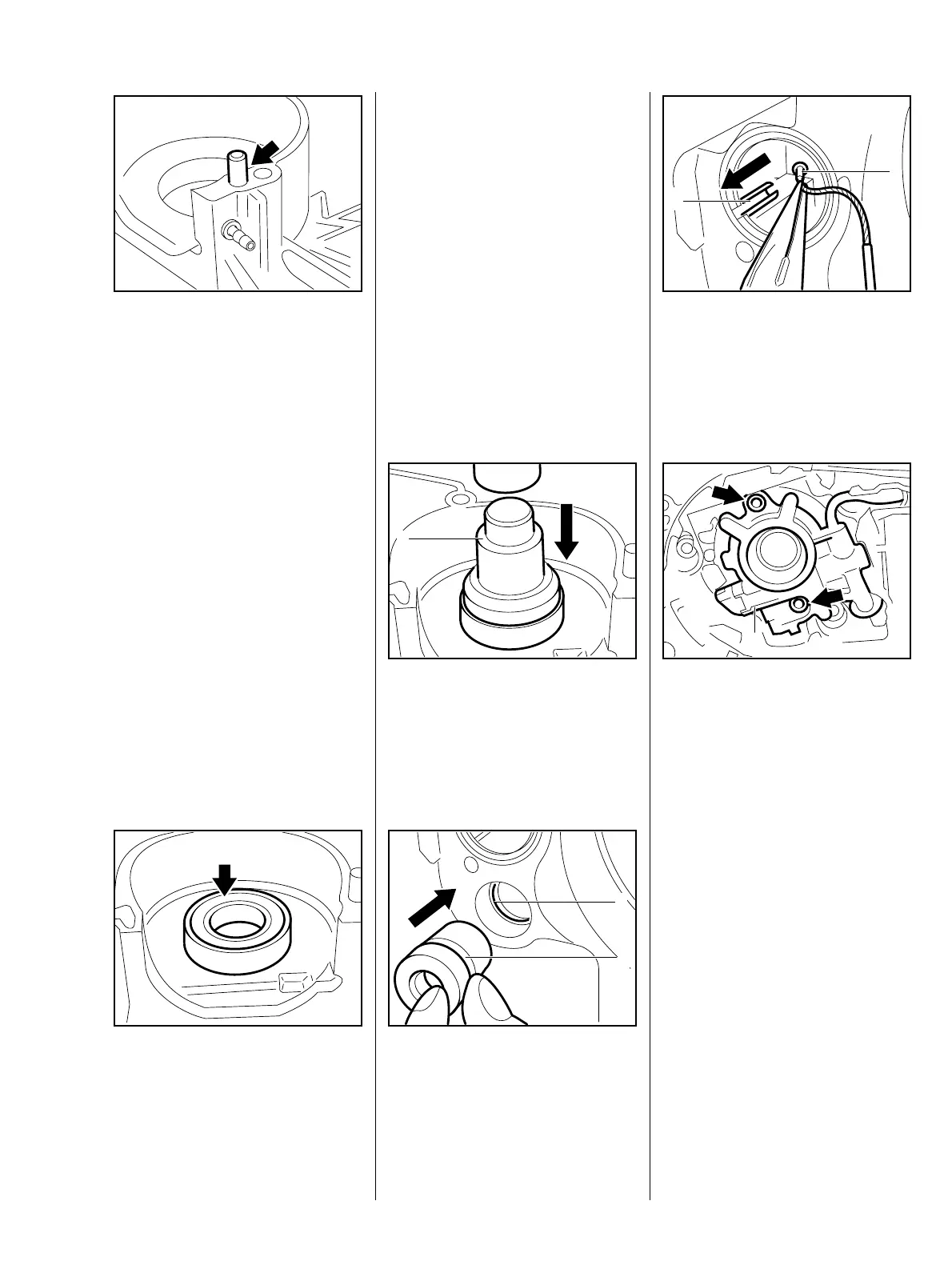

: The straight pin (arrow) must be

fitted; if not, it must be driven into

the crankcase.

– Heat the fan side of the

crankcase to approx. 150 °C

(302 °F) around the ball bearing

seat.

VA

176RA118

: Press the deep groove ball

bearing (arrow) as far as possible

into the crankcase by hand with

the closed side facing upwards.

VA

176RA119

This operation must be carried out

very quickly because the bearing

absorbs heat immediately and

begins to expand.

: If it is not possible to heat the

clutch side of the crankcase, use

press arbor (1) 1118 893 7200 to

press home the ball bearing as

far as stop.

VA

176RA120

1

– Let the crankcase cool.

: Press the annular buffer in so that

the circumferential groove (1)

engages the edge of the

crankcase (2).

VA

176RA121

2

: Fit nipple of tank cap cord (1) in

the slot (2) and pull it forwards.

VA

176RA122

2

1

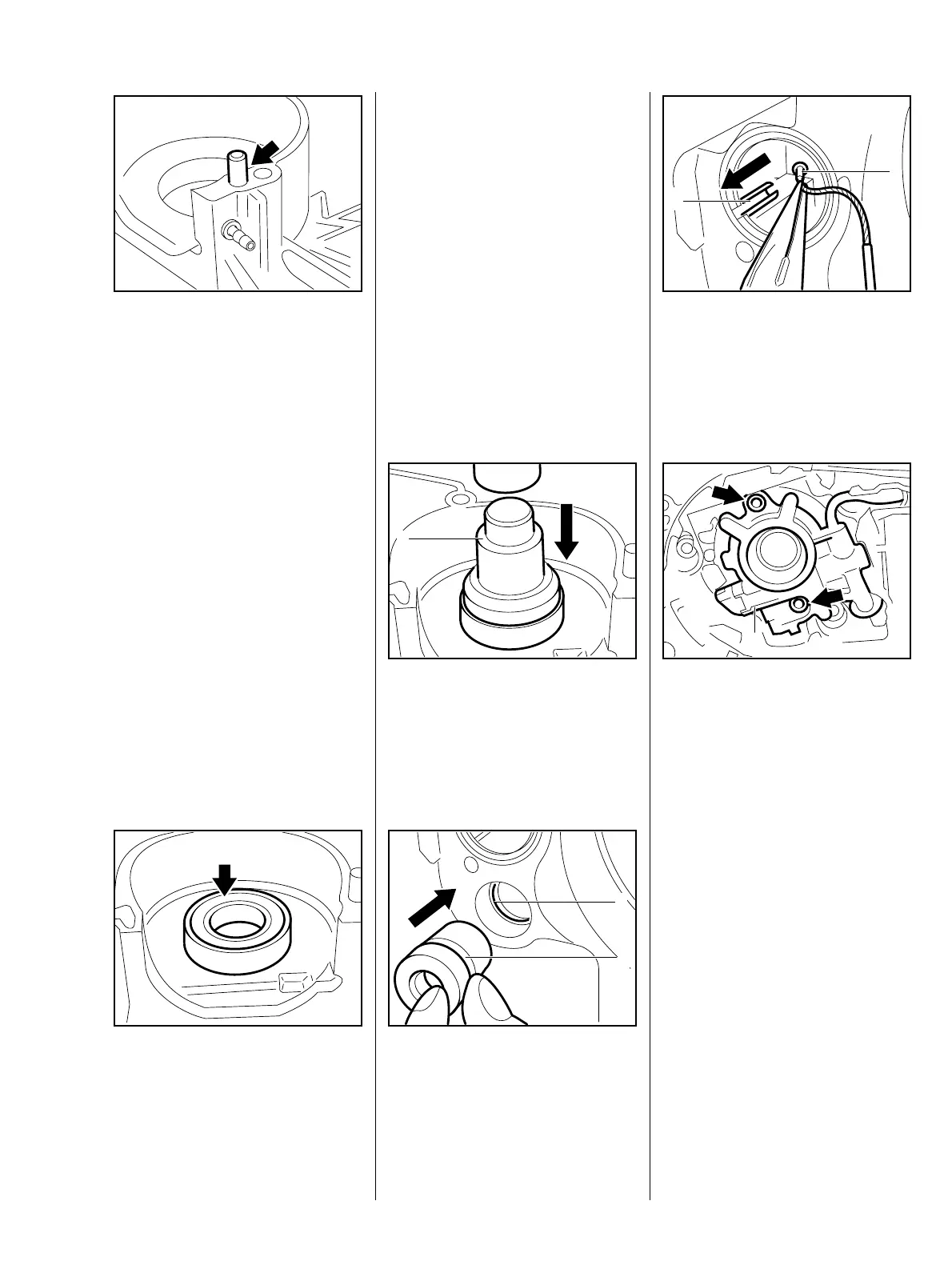

The oil pump must be fitted as stop

when installing the deep groove ball

bearing.

– Position the oil pump (1).

– Insert the screws (arrows) and

tighten them down – b 3.5

VA

175RA024

1

– Heat the area of the ball bearing

on the clutch side of the

crankcase to about 150 °C

(302 °F).

Loading...

Loading...