68 MS 440, MS 440 C

In the case of problems with the

carburetor or fuel supply system,

also check and clean or replace the

tank vent – b 12.5

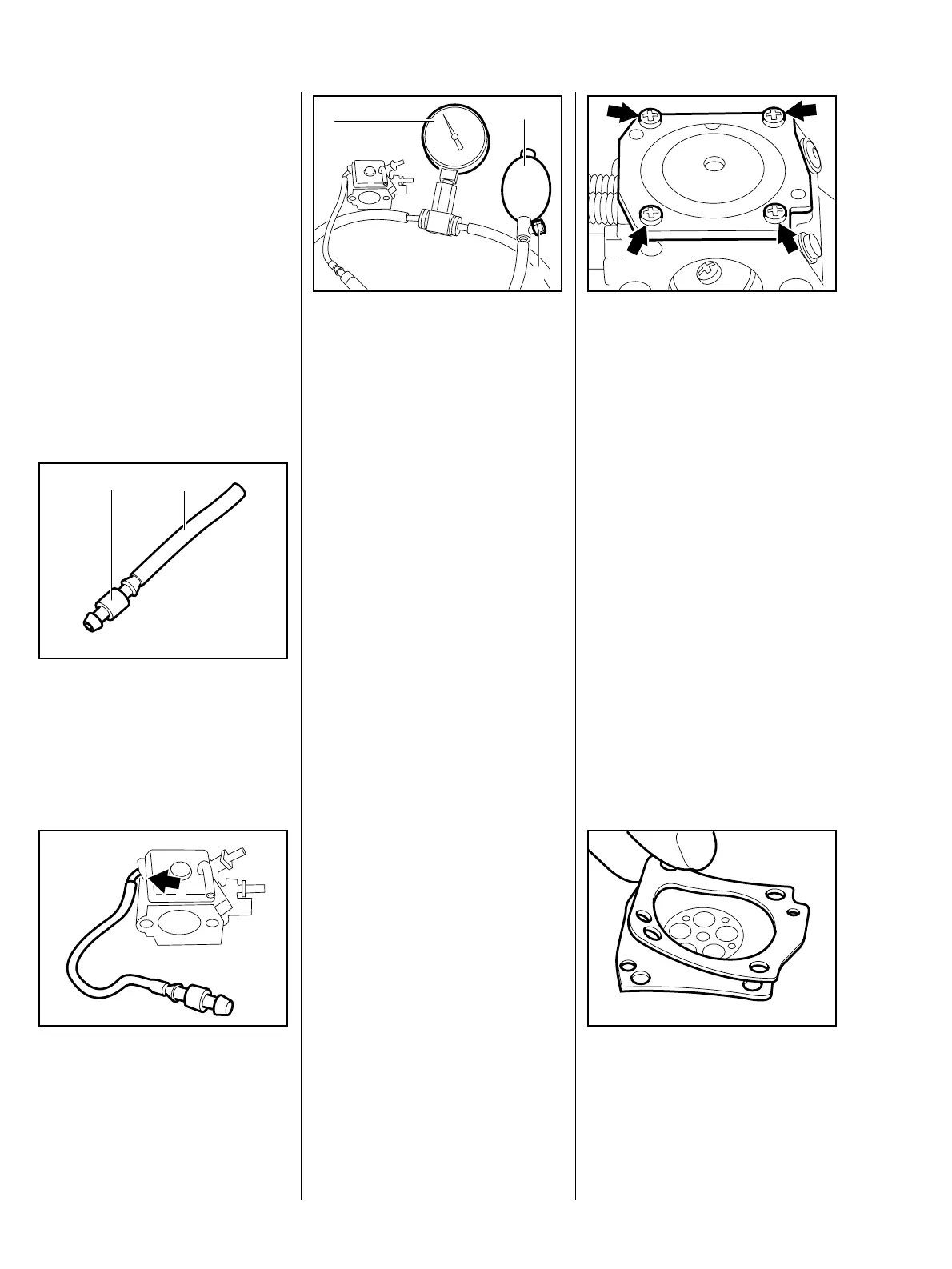

The carburetor can be tested for

leaks with the carburetor and

crankcase tester 1106 850 2905.

– Remove the carburetor –

b 12.2.1

: Push the fuel line (1)

1110 141 8600 onto the

nipple (2) 0000 855 9200.

VA

143RA172

2 1

: Push the fuel line with nipple onto

the carburetor’s elbow connector.

VA

176RA264

: Push the fuel line with nipple onto

the carburetor’s elbow connector

1106 850 2905.

: Close the vent screw (1) on the

rubber bulb (2) and pump air into

the carburetor until the pressure

gauge (3) shows a reading of

VA

176RA265

2

1

3

approx. 0.8 bar (11.60 psi).

If this pressure remains constant,

the carburetor is airtight. However, if

it drops, there are two possible

causes:

1. The inlet needle is not sealing

(foreign matter in valve seat or

sealing cone of inlet needle is

damaged or inlet control lever

sticking). Remove to clean –

b 12.3.2

2. Metering diaphragm damaged,

replace if necessary – b 12.3.1

– After completing the test, open

the vent screw (1) and pull the

fuel line off the carburetor.

– Push the fuel hose onto the

elbow connector.

– Install the carburetor – b 12.2.1

Reassemble all other parts in the

reverse sequence.

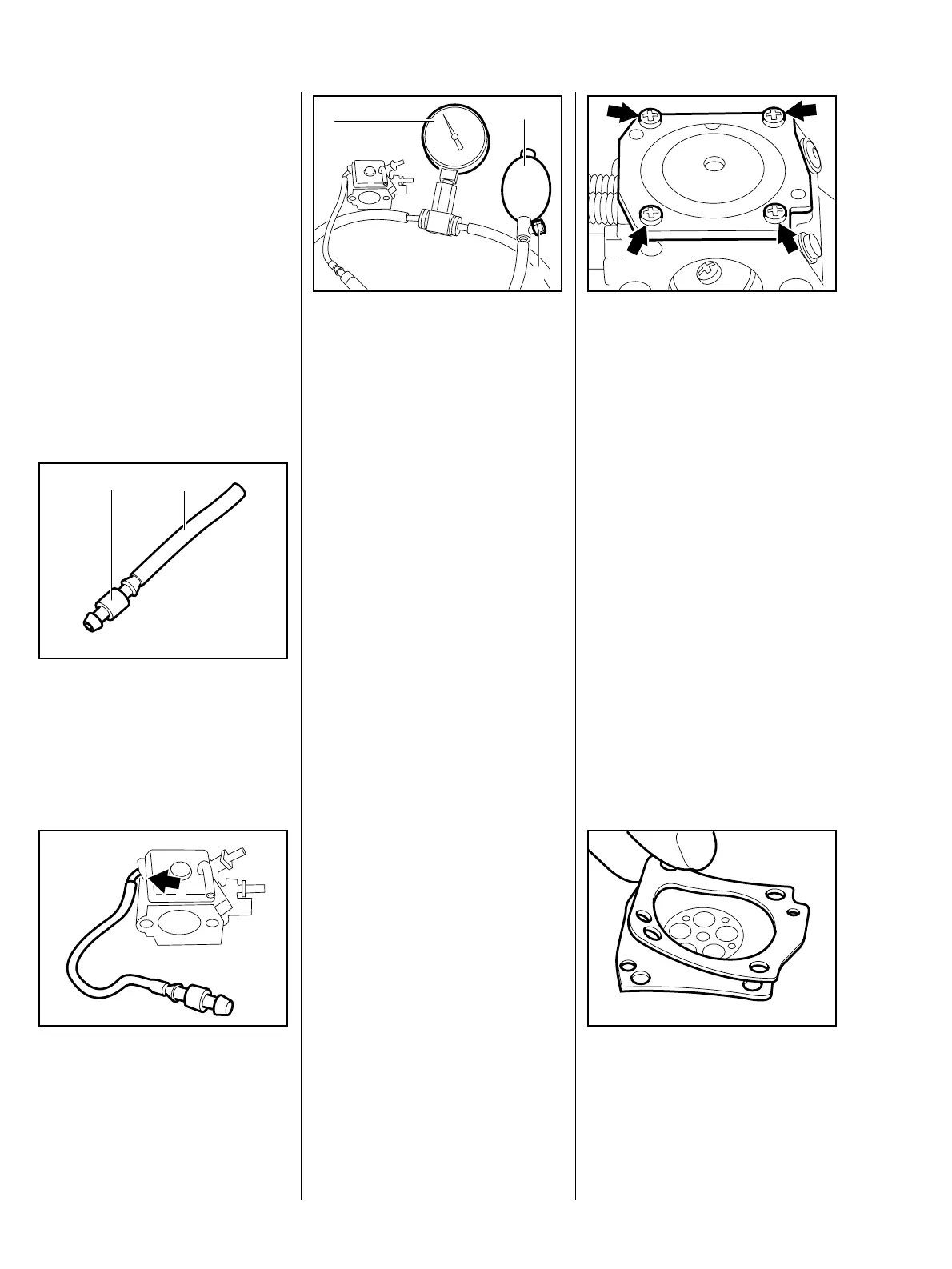

– Remove the carburetor –

b 12.2.1

: Take out the screws (arrows).

– Remove the end cover.

– Carefully remove the gasket and

VA

176RA270

pump diaphragm from the end

cover.

: Carefully separate the diaphragm

and gasket.

– Examine the diaphragm for signs

of damage or wear, replace if

necessary.

VA

176RA272

12.2.2 Leakage Test 12.3 Servicing the Carburetor

12.3.1 Metering Diaphragm

Loading...

Loading...