74 MS 440, MS 440 C

Correct operation of the carburetor

is only possible if atmospheric

pressure and internal fuel tank

pressure are equal at all times. This

is ensured by the tank vent.

Important!

In the event of trouble with the

carburetor or the fuel supply

system, always check and clean the

tank vent.

Check function by performing

vacuum test on the tank via the fuel

hose.

– Remove the carburetor –

b 12.2.1

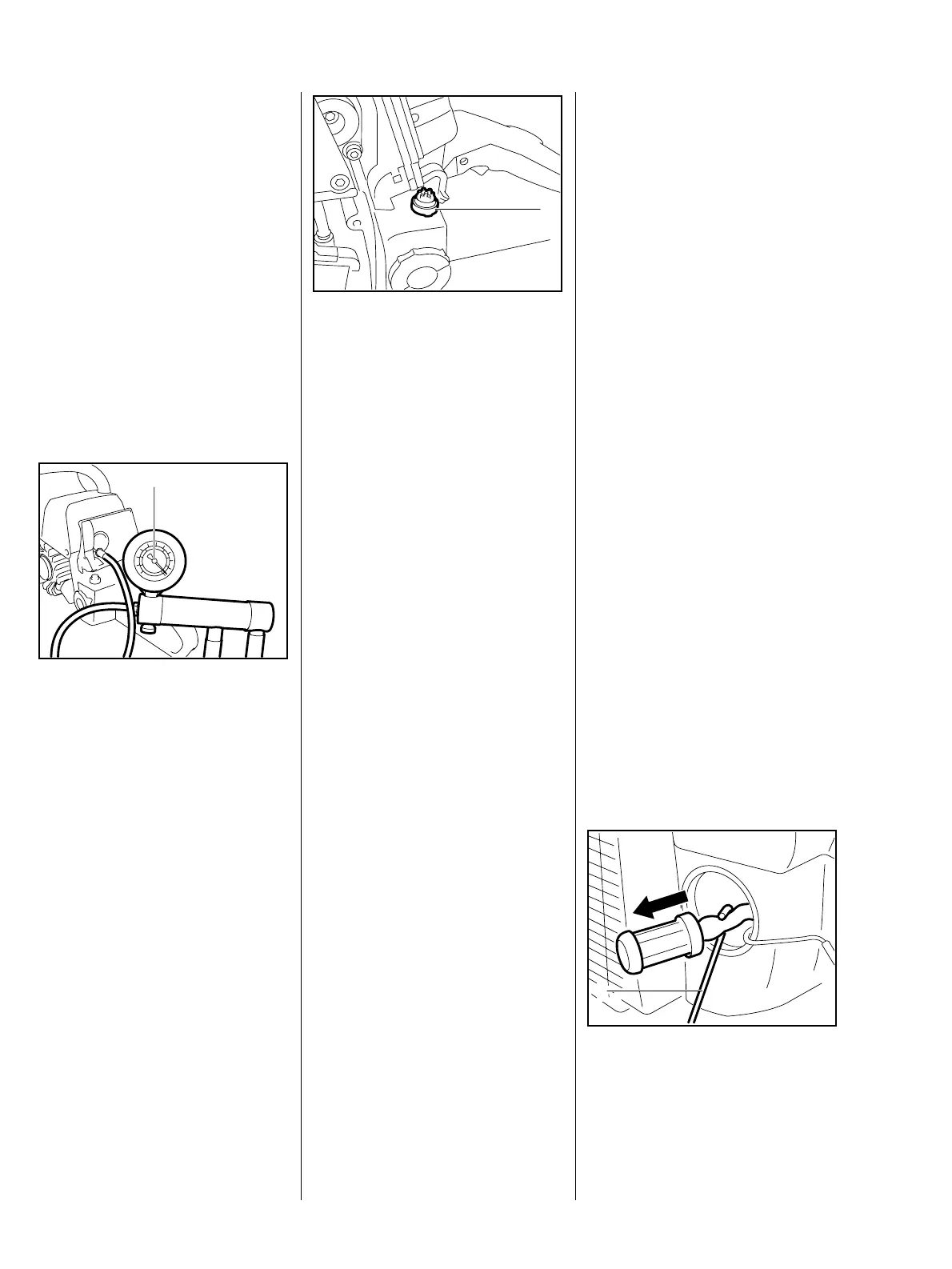

: Connect service tool (1)

0000 850 3501 to the fuel hose

and create a vacuum in the fuel

tank.

VA

176RA294

1

: Equalization of pressure takes

place via the tank vent (1). There

must not be any build-up of

vacuum in the tank. In the event

of a malfunction, pry out the tank

vent with a slotted screwdriver

and fit a new valve with new

O-ring.

VA

176RA290

1

The diaphragm pump draws fuel

from the tank into the carburetor

through the fuel hose. Any

impurities mixed with the fuel are

retained by the pickup body. The

fine pores of the filter eventually

become clogged with minute

particles of dirt. This restricts the

passage of fuel and results in fuel

starvation.

In the event of trouble with the fuel

supply system, always check the

fuel tank and the pickup body first.

Clean the fuel tank if necessary.

Cleaning the fuel tank

: Remove the fuel tank cap and

drain the tank.

– Pour a small amount of clean

gasoline into the tank. Close the

tank and shake the saw

vigorously.

– Open the tank again and drain it.

Dispose of fuel properly in

accordance with environmental

requirements!

Pickup body

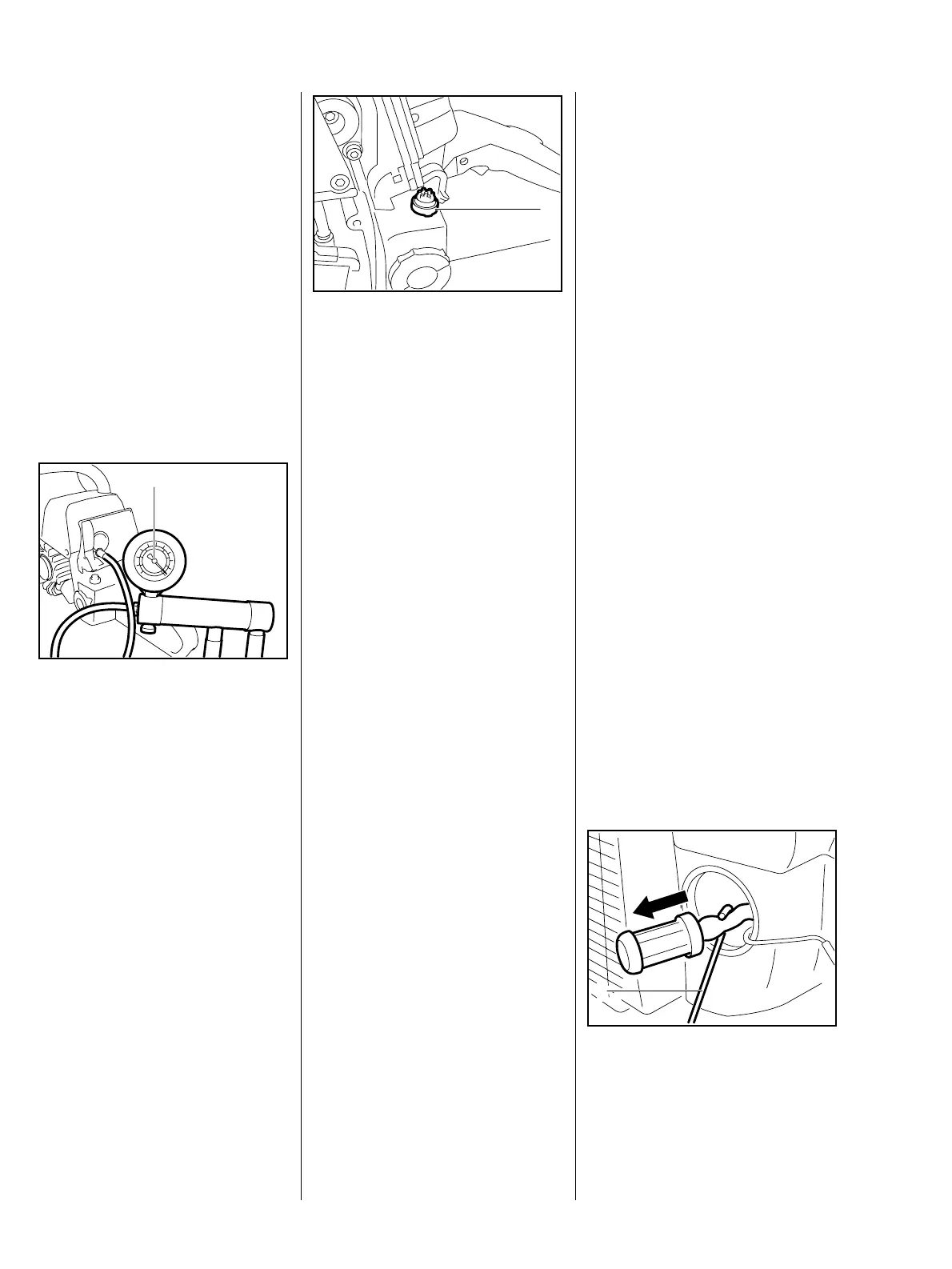

: Use hook (1) 5910 893 8800 to

pull the pickup body out of the

fuel tank.

Do not stretch the fuel hose too

much during this operation.

VA

176RA297

1

12.5 Tank Vent 12.6 Pickup Body

Loading...

Loading...