Theory of Operation

Model 315I (UC Ice Maker)

3-4

#3757320 - Revision B - August, 2005

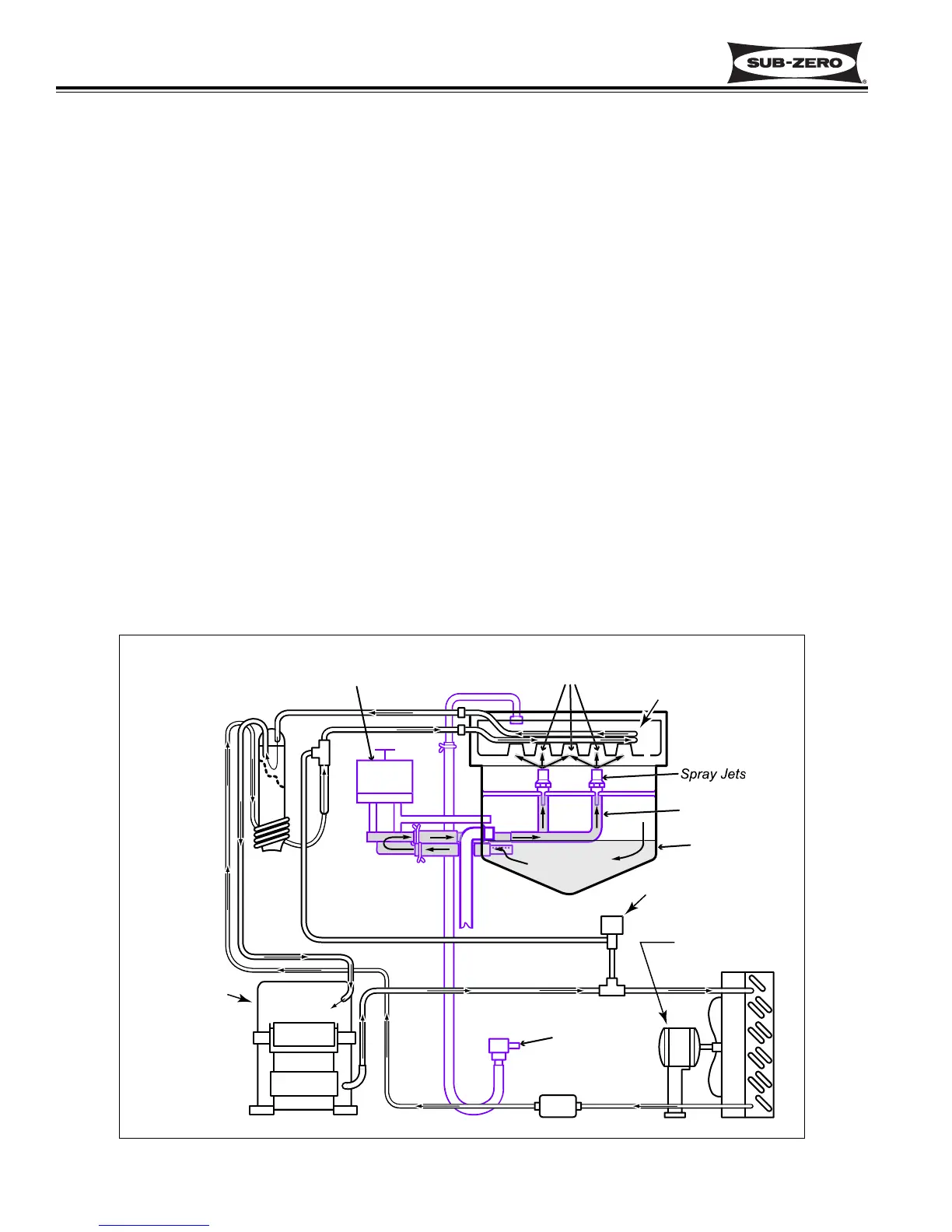

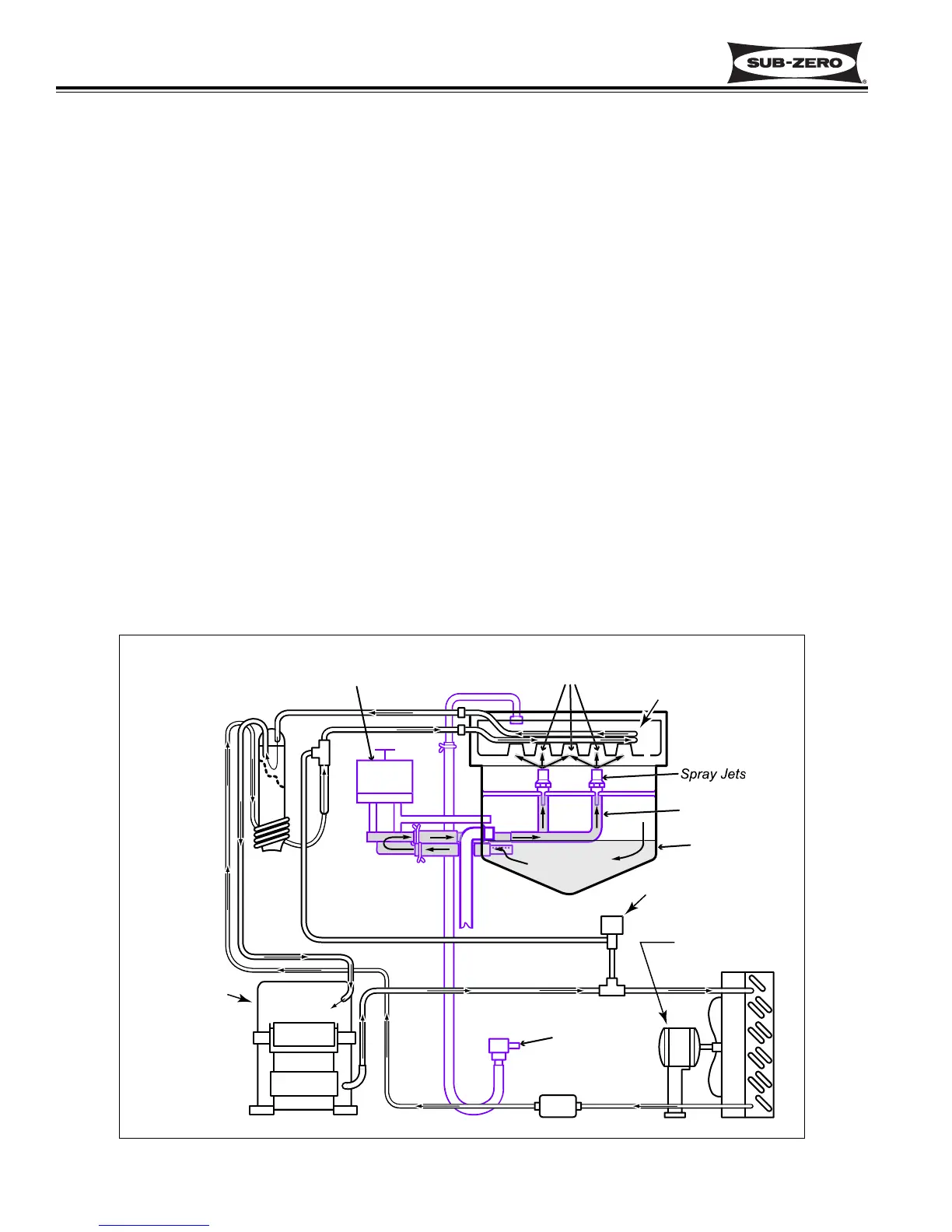

OPERATIONAL CYCLES

There are two operational cycles of the icemaker:

• Ice Making (Freeze) Cycle

• Harvest Cycle

The ice making (freeze) cycle happens when water from the reservoir is sprayed into the ice cube molds at the bot-

tom of the evaporator and the water freezes into cubes. The harvest cycle is when the ice cubes are released from

the cube molds and fresh water enters the reservoir. The complete process takes approximately 30 minutes for

each batch of ice. (1 Freeze Cycle + 1 Harvest Cycle = 1 Batch of 8 Cubes.)

Ice Making (Freeze) Cycle

During the ice making cycle the compressor pumps refrigerant through the system, the condenser fan draws air over

the condenser, and the circulating spray pump sprays water into the cube molds. The refrigerant running through

the evaporator absorbs heat from the water being sprayed into the cube molds and the water begins to freeze. The

heat that the refrigerant absorbs from the water is carried in the refrigerant back to the compressor and then through

the condenser where the heat is transferred from the refrigerant to the air being drown over the condenser tubing by

the condenser fan. This warm air is discharged out through the louvered kickplate. When the cube molds become

cold enough, the ice machine’s timer begins to turn. When the timer turns far enough, it stops the ice making

(freeze) cycle and begins the harvest cycle.

NOTE: The Water System During Ice Making (Freeze) Cycle - The water system initially fills the reservoir with

approximately two quarts of water. During the ice making cycle, water is taken from the reservoir and sprayed into

the cube molds where it begins to freeze. But, due to the fact that water containing mineral impurities needs a lower

temperature to freeze, the impure water falls back into the reservoir and the purer water freezes in the cube molds.

This causes the water in the reservoir to become highly concentrated with mineral impurities towards the end of the

ice making (freeze) cycle.

Figure 3-4. Ice Making (Freeze) Cycle

Loading...

Loading...