TS20C USER MANUAL SECTION 4

102

In installations that include more than one

compressor, hot air exhaust should not be directed

toward the fresh air intake of the second unit or an air

dryer.

A standard machine installed outside must not be

started or run if the ambient temperature on and

around the compressor drops or may drop below

35ºF (1.7ºC).

For installation in a below freezing climate, a low

ambient option with heat tracing and a separator/

sump tank heater must be installed.

WATER-COOLED COMPRESSORS

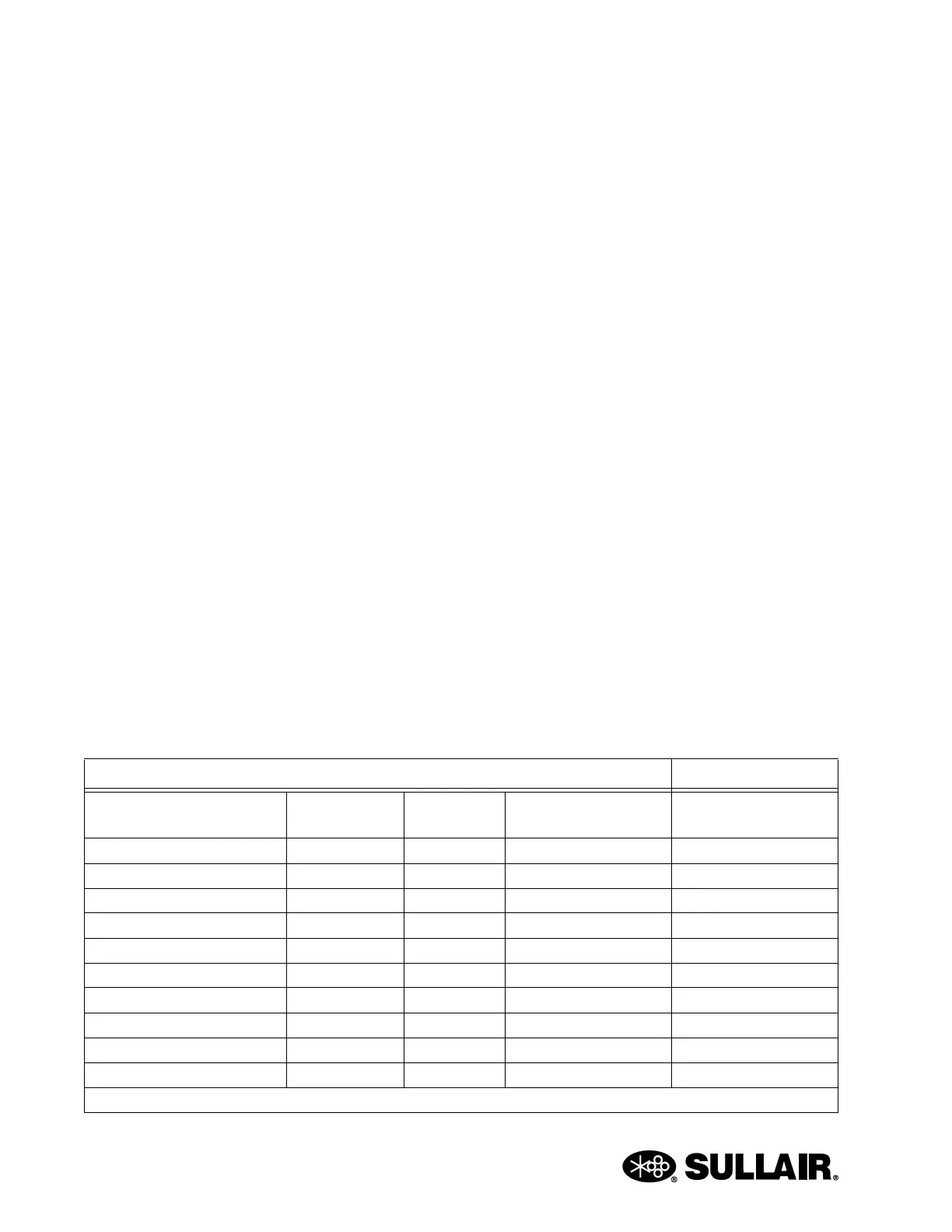

Adequate cooling water flow must be supplied to

water-cooled compressors. Water delivery must be

verified to assure constant delivery per columns

outlined in Table 4-1: Water Flow Requirements. The

figure shown are for full-load operation utilizing an

aftercooler. Cooler water will reduce water-flow

requirements and warmer water will increase water-

flow requirements.

Consult the Sulliar Service Department for

assistance in these setups.

Water quality is critical to proper cooling of the

compressor. Excessive build-up of lime, scale or

other deposits can restrict the flow of water to the

compressor. These deposits act as a thermal

insulator and reduce the efficiency of the water

cooler.

The cleaning of piping and water coolers is the

customer’s responsibility. Inspect all piping for

deposits and clean as necessary. Refer to Water

Quality Recommendations on page 103.

Table 4-2: Ventilation Requirements indicates the

minimum ventilation requirements necessary to keep

the compressor running at its normal operating

temperature. The fan air requirement is the amount

of air, which must flow through the compressor for

proper ventilation. The heat rejection is the amount of

heat that is radiated by the compressor. This heat

must be removed to assure a normal operating

temperature. With air-cooled compressors (100-

200HP) it is possible to use this heat for space

heating, providing additional pressure drop across

the fan does not exceed 0.2 in W.C. Consult a Sullair

office for assistance in utilizing this heat. If ductwork

is added, the high static fan option is required.

DO NOT install compressor where it will be exposed

to temperatures less than 32ºF (0ºC) without freeze

protection. Consult factory for machine operation in

ambient temperature less than 32ºF (0ºC).

If machine is equipped with water regulating valve,

use the water regulating valve to adjust compressor

temperature to maintain a minimum of 180ºF

(82.2ºC); 190ºF (87.8ºC) for 24KT.

Temperature and pressure gauges should be

installed in the water piping for use in troubleshooting

of the water system. Water pressure should ideally

be between 25 and 75 psig (1.7 to 5.2 bar) but must

not be above 145 psig (10 bar).

Table 4-1: Water Flow Requirements

HP/kW

Water Temp.

ºF (ºC)

Water Flow (Typical)

GPM

Water Flow (Typical)

LPM

TS20C/V200TS 100HP/75kW 70 (21) 14.0 15.3

TS20C/V200TS 100HP/75kW 80 (27) 18.75 71

TS20C/V200TS 125HP/93kW 70 (21) 17.5 66

TS20C/V200TS 125HP/93kW 80 (27) 23.5 89

TS20C/V200TS 150HP/112kW 70 (21) 21.0 79.5

TS20C/V200TS 150HP/112kW 80 (27) 28.0 106

TS20C/V200TS 200HP/150kW 70 (21) 40 151

TS20C/V200TS 200HP/150kW 80 (27) 44 166

TS20C/V200TS 250HP/187kW 70 (21) 49 185

TS20C/V200TS 250HP/187kW 80 (27) 54 204

NOTE: Recommended water pressure range is 25 to 75 psig (1.7 to 5.2 bar).

Loading...

Loading...