TS20C USER MANUAL SECTION 4

104

to Table 4-3: Water Tests.

SEAWATER-COOLED UNITS

Water cleanliness is critical for operation of the

compressor. A strainer must be installed in the inlet

piping of the water system. It is also recommended

that a solenoid valve (normally closed) be installed

into the water outlet side of the compressor system.

Consult the Sulliar Service Department for

assistance in setting up these recommended

precautionary functions. In addition, be aware the

cleaning of coolers as a result of fouling is a

customer responsibility.

The recommended flow rate cannot be exceeded. An

orifice plate must be installed in the pipe-work at

least 3.3 ft (1 m) before the cooler. The orifice size

must be calculated to ensure that the maximum

seawater flow rate cannot be exceeded. Without

these precautions, the seawater flow rate through the

cooler may be several times the recommended

maximum, which will lead to rapid system failure.

No oil cooler manufacturer can guarantee that its

products will have an indefinite life and for this

reason, we suggest that the cooling system be

designed to minimize any damage caused by oil

cooler leaking. This can be achieved as follows:

The oil pressure should be maintained at a pressure

higher that the seawater pressure. In the event of a

leak occurring, the oil will be prevented from

becoming contaminated.

When the hydraulic system is not in use, the coolers

should be isolated from incoming seawater under

pressure.

The seawater outlet pipe from the cooler should have

an open run to waste piping.

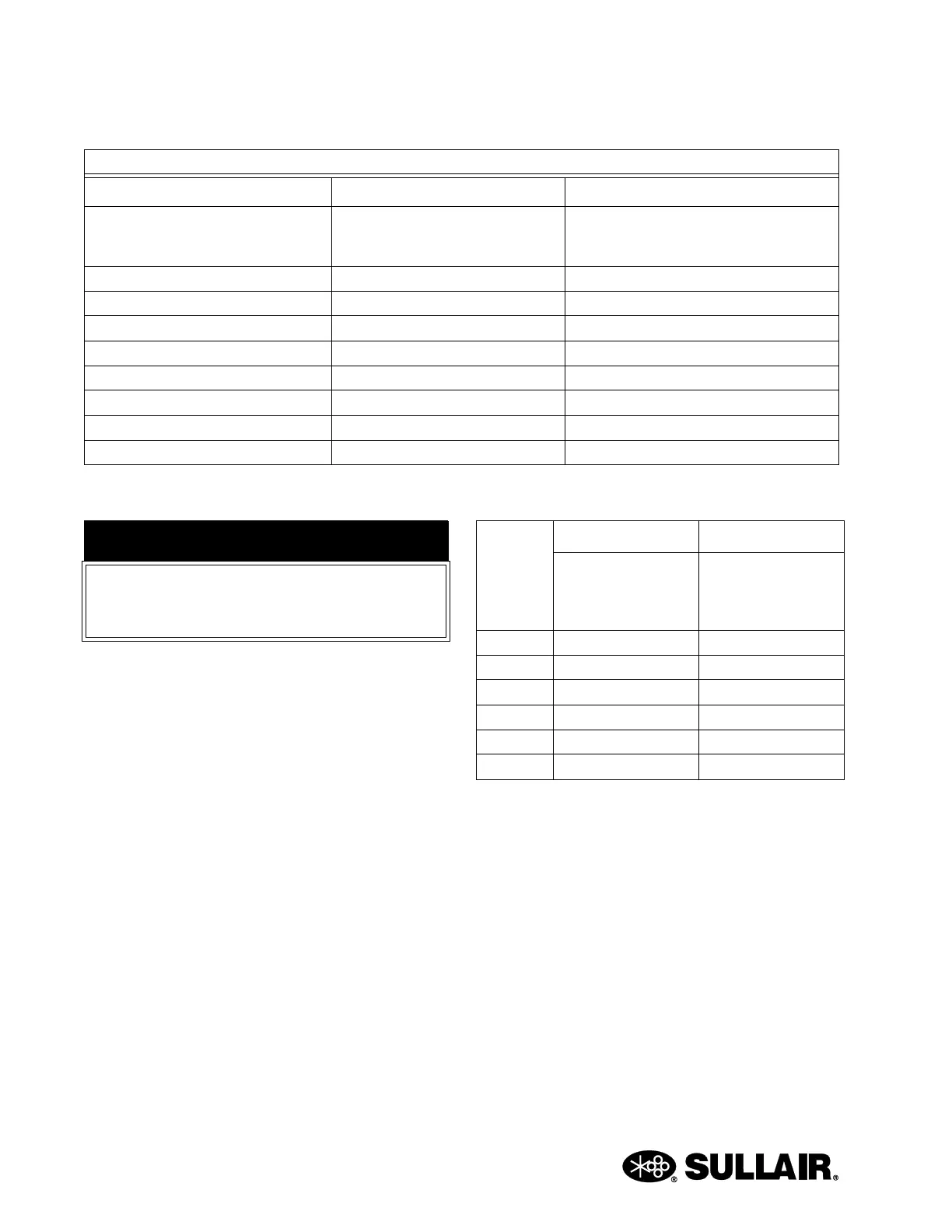

Table 4-3: Water Tests

Substances Test Interval Acceptable Concentration

Corrosivity Hardiness, pH, Total Dis-

solved Solids, Temperature at inlet,

Alkalinity

Monthly-if stable for 3 to 4 months,

analyze quarterly

Langerlier Index 0 to 1

Iron Monthly <2 ppm

Sulphate Monthly <50 ppm

Chloride Monthly <50 ppm

Nitrate Monthly <2 ppm

Silica Monthly <100 ppm

Desolated Oxygen Daily-if stable, analyze weekly <0 ppm (as low as possible)

Oil & Grease Monthly <5 ppm

Ammonia Monthly <1 ppm

NOTE

If seawater is to be used for cooling,

optional copper-nickel coolers must be

selected.

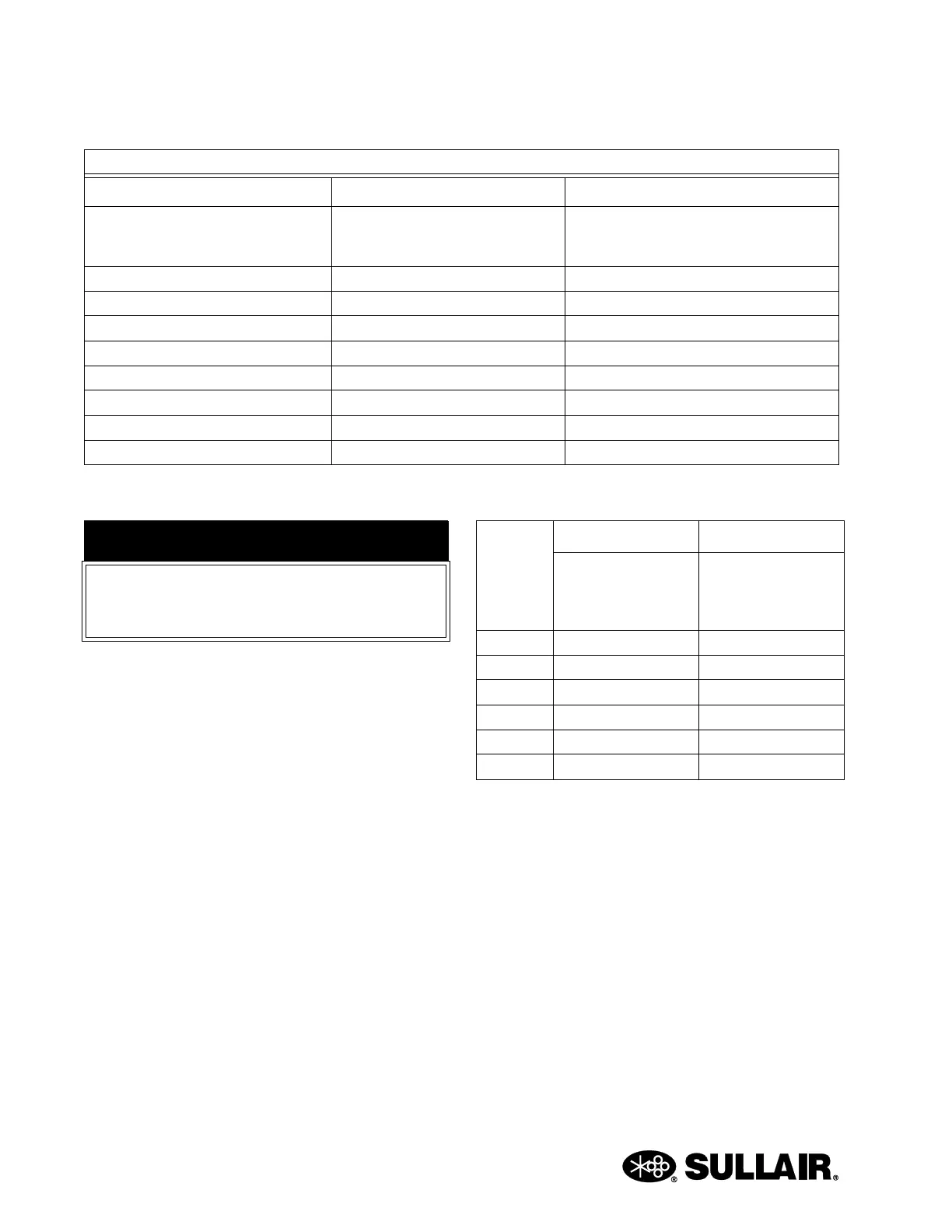

Seawater

Pressure

psi (bar)

100/150HP 200/250HP

Orifice size for 80 GPM

orifice diameter in inch

(mm) to give a maximum

seawater flow of

80 GPM (302.8 l/min)

Orifice size for 160 GPM

orifice diameter in inch

(mm) to give a maximum

seawater flow of

160 GPM (605.6 l/min)

25 (1.7) .95 (24.1) 1.35 (34.3)

35 (2.4) .88 (22.4) 1.24 (31.5)

45 (3.1) .82 (20.8) 1.16 (29.5)

55 (3.8) .78 (19.8) 1.10 (27.9)

65 (4.45) .75 (19.1) 1.06 (26.9)

75 (5.2) .72 (18.3) 1.02 (25.9)

Loading...

Loading...