Cyclo® BBB4

30 Operation & Maintenance Manual

Cyclo® BBB4

Lubrication, continued

Lubrication Method

Lubrication Method

Using the model number and mounting configuration, refer to Tables 20 and 21 to determine the unit’s lubrication method.

Table 20. Lubrication Method for Configurations Y1, Y2, Y3, Y5, Y6

Mounting Configuration

Unit Size

Lubrication Method

Bevel Gear

Size

Cyclo® Size

4A - 4F

100, 105,

110, 115,

120, 125,

140, 145

160, 165,

170. 175,

180, 185,

190, 195

10DA, 12DA,

12DB, 14DA,

14DB, 14DC,

16DA, 16DB,

17DA, 17DB,

17DC

Complete Unit

(Bevel Gear Portion

and Cyclo® Portion)

Common Oil Sump

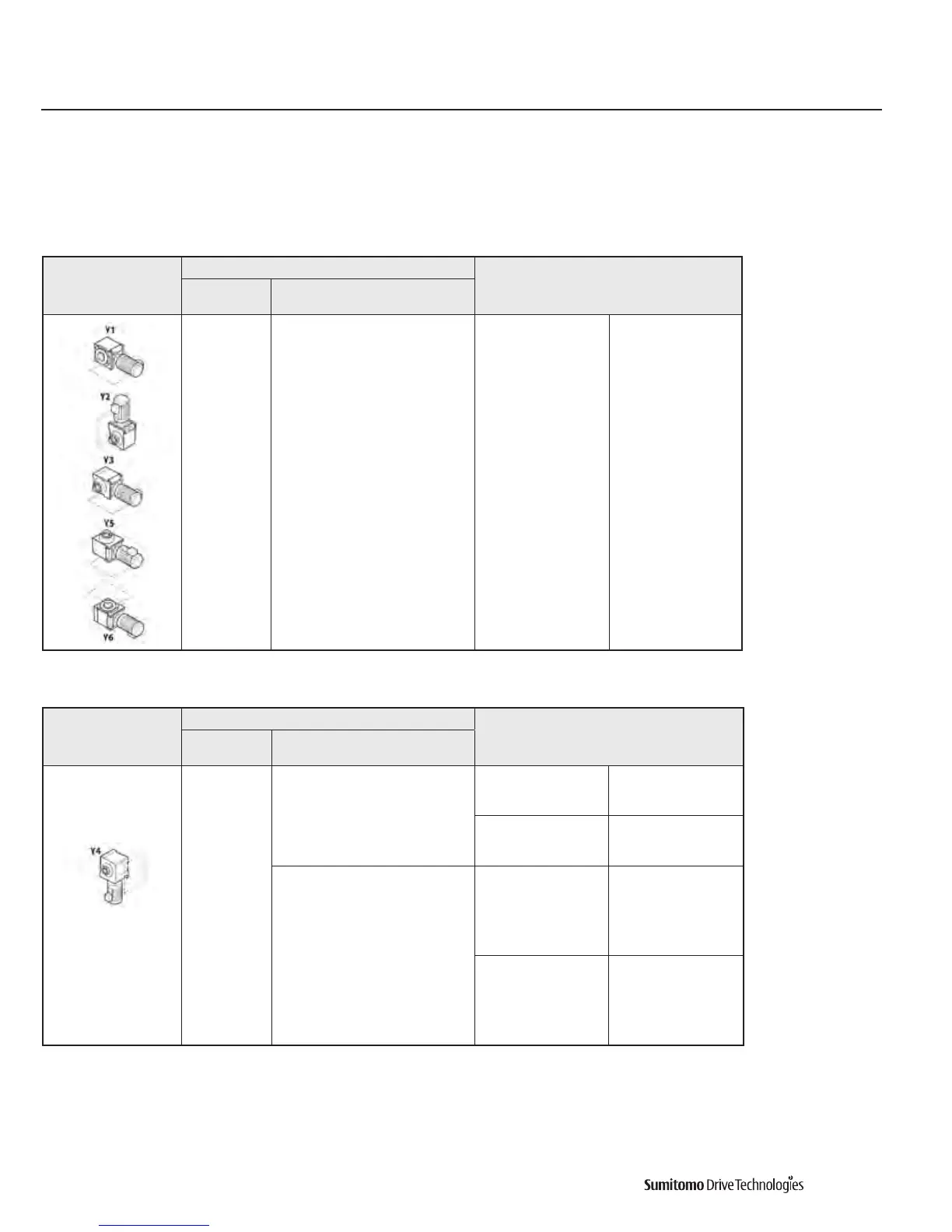

Table 21. Lubrication Method for Y4 Configuration

Mounting Configuration

Unit Size

Lubrication Method

Bevel

Gear Size

Cyclo® Size

4A-4F

100, 105,

110, 115,

120, 125

10DA, 12DA, 12DB

Cyclo® Portion

Maintenance Free

Grease

[1]

Bevel Gear Portion Oil

140, 145,

160, 165,

170, 175

180, 185,

190, 195

14DA, 14DB, 14DC,

16DA, 16DB,

17DA,17DB, 17DC,

18DA, 18DB,

19DA, 19DB

Cyclo® Portion Grease

[2]

Bevel Gear Portion Oil

Notes: [1] Maintenance Free Grease: the input Cyclo® portion is grease lubricated as standard from the factory and usually does not require replacement or replenishment.

[2] Grease: the input Cyclo® portion is grease lubricated as standard from the factory. Please refer to Tables 27, 28 and 29 for the proper grease replenishment and change interval.

Loading...

Loading...