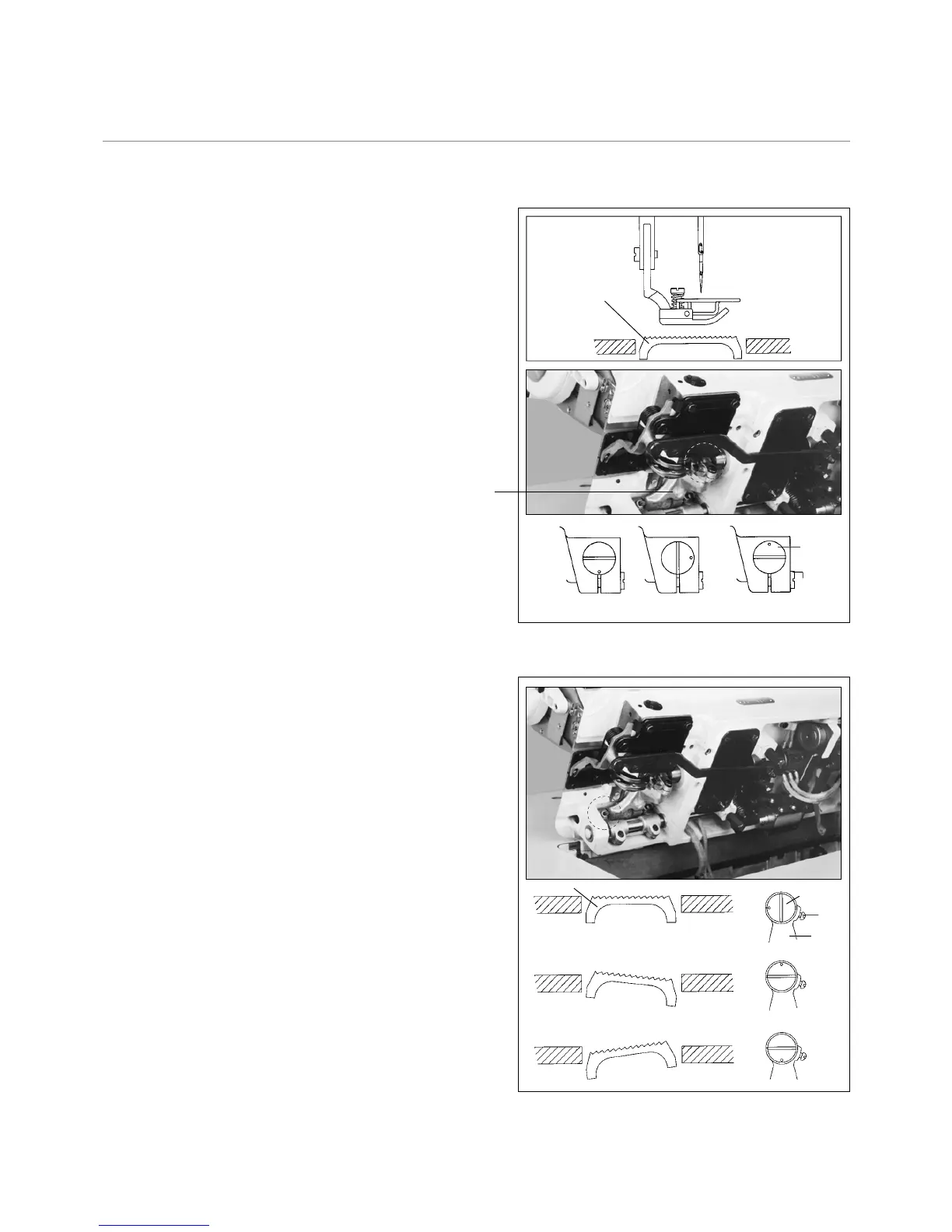

4) Feed Dog Height Adjustment

Standard height is 1mm when the feed dog① went up the

most from needle plate upper face.

A. Make the transfer value① to stop at the highest location

by turning the sewing machine pulley.

B. Lay down the sewing machine.

C. Unscrew the fixing screw②.

D. Adjust feed dog support④ making to move up and down

by turning the eccentric axis③ of feed dog support.

E. Fasten fixing screw② tightly.

[ Fig. 27 ]

The highest location

Standard

the Lowest lacatiobn

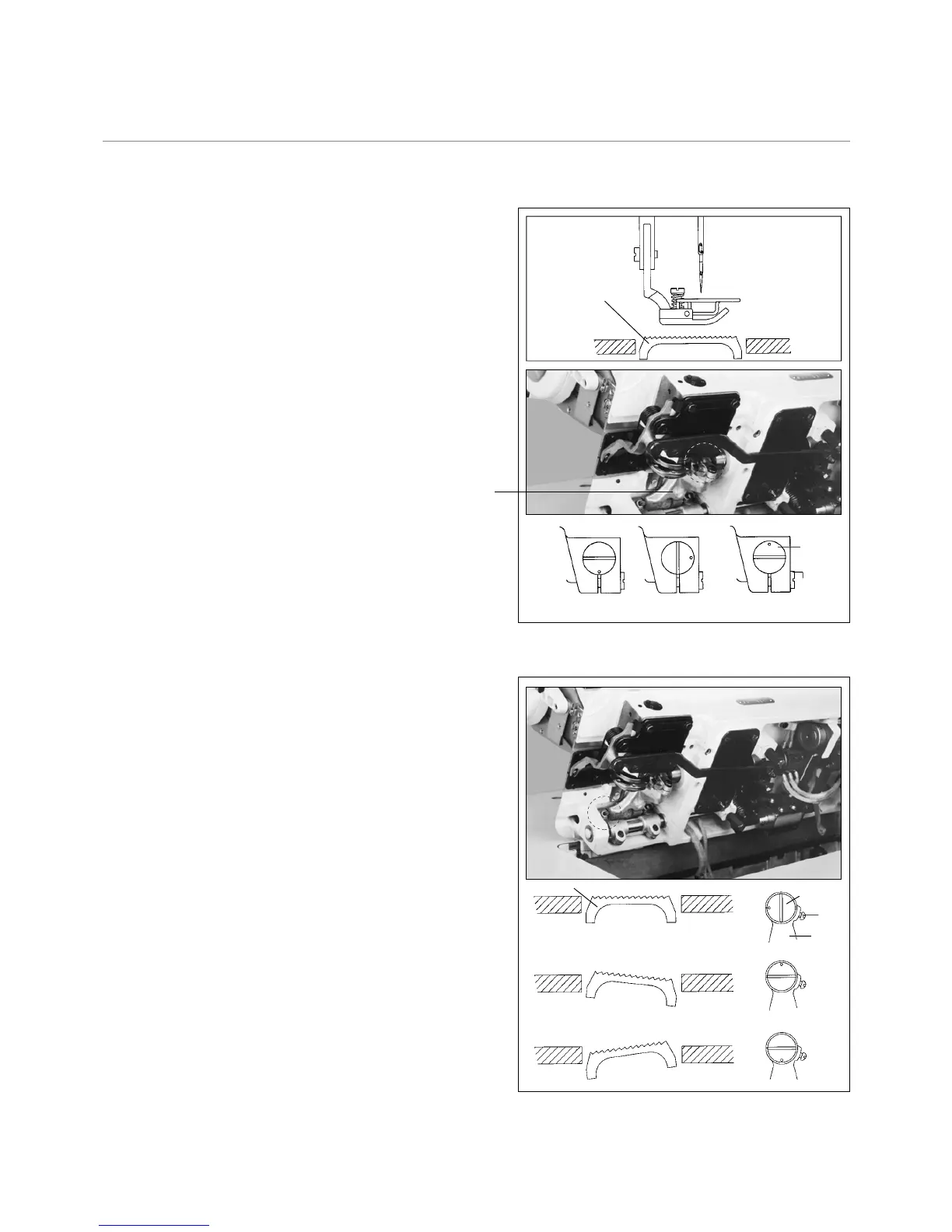

5) Feed Dog Slope Regulation

When the feed dog① went up to the maximum from

upper face of needle plate, standard slope is made

that upper face of needle plate and upper face of feed

dog should be parallel.

(0 mark on eccentric axis ② of feed rolling bracket

matches with the mark on feed rolling bracket③.)

A. Make the feed dog① to stop at the highest location by

turning the sewing machine pulley.

B. Lay down the sewing machine.

C. Unscrew 2 pieces of stop screw④.

D. Adjust eccentric axis②of feed rolling bracket by turning

within 90°to arrowed direction against standard location.

· Place the slope of upper face of feed dog① downward

direction to the user's side in order to prevent

puckering. (Figure A)

Place the slope of upper face of feed dog① upward to

the user's side to prevent the cloth to go crisscross.

(Figure B)

E. Fasten fixing screw④ (2 pieces) tightly.

Adjusting the slope of feed dog①, height of feed dog①

and location front and back changes. Hence, please

adjust again.

[ Fig. 28 ]

User’s side

24

①

④

③

②

①

②

④

(A Fig.)

(B Fig.)

③

Loading...

Loading...