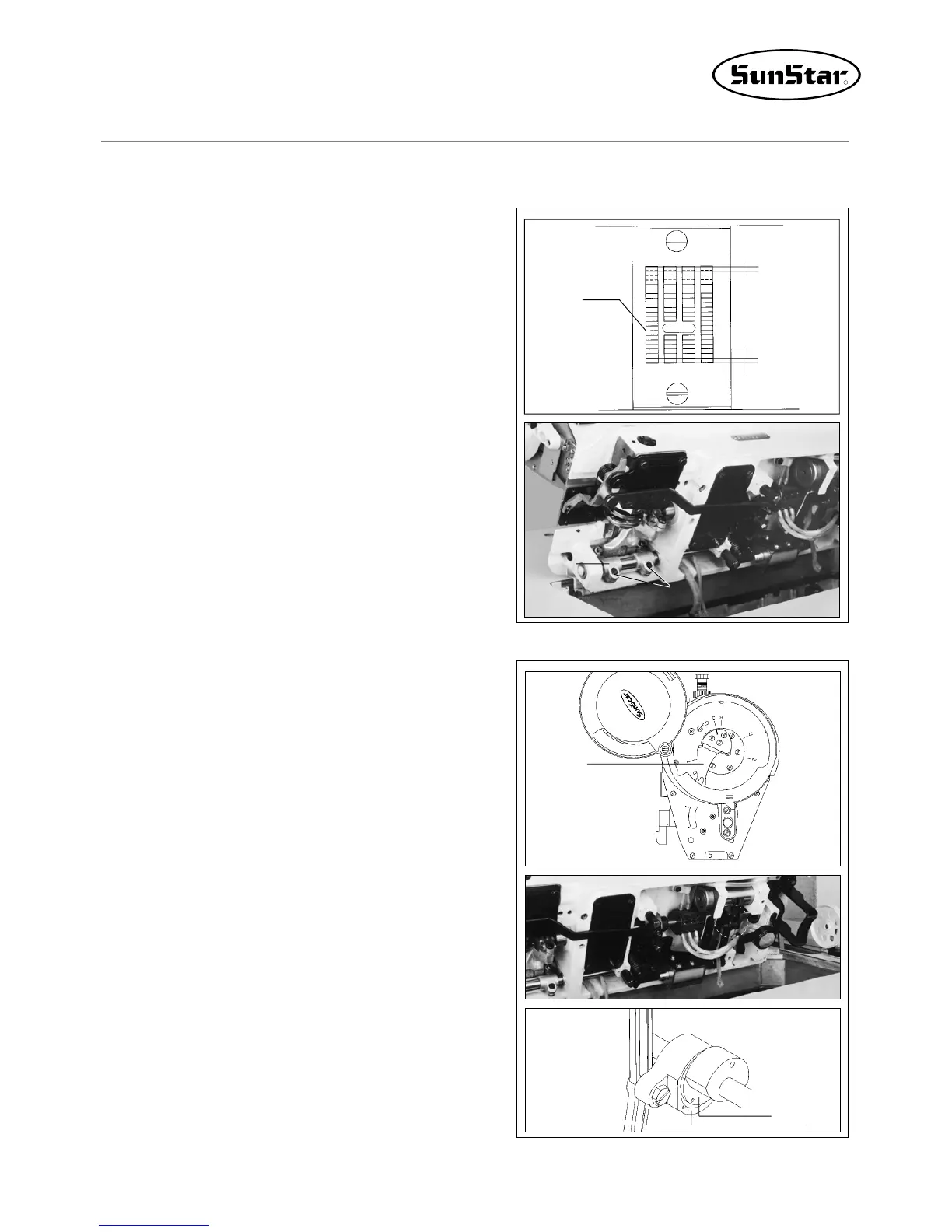

6) Feed Dog Front and Back Adjustment

Gap front and back to the needle plate when the feed dog①

moved closest to the user's side and when it moved to the

most backward by turning the sewing machine pulley

becomes regular.

A. Lay down the sewing machine.

B. Unscrew the fixing screw② (2 pieces).

C. Adjust by turning the feed rolling bracket③ and then

moving the feed dog①.

D. Fasten fixing screw② tightly.

[ Fig. 29 ]

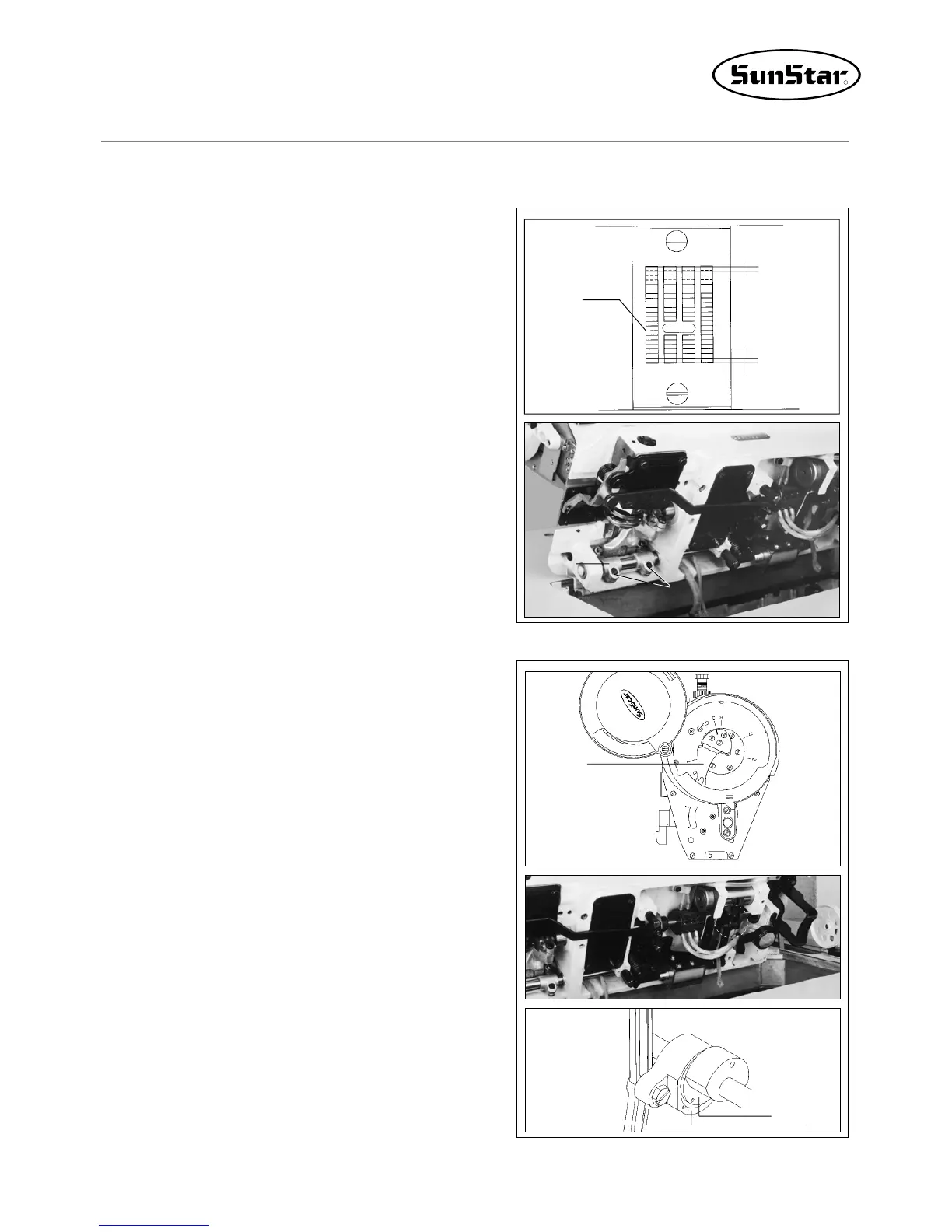

7) Needle and Transfer Timing

Make 0 mark of feed cam bearing cover② and 0 mark of

feed cam connection rod③ to match each other when

matched base line of thread take-up① to C mark of face

plate.

A. Lay down the sewing machine.

B. Match the base line of thread take-up① to B mark of face

plate.

C. Unscrew the fixing screw (4 pieces) of lower shaft timing

pulley.

D. Turn the feed cam bearing cover② and match 0 mark to

the 0 mark of feed cam connection lot③.

E. Fasten fixing tightly (4 pieces) of lower shaft timing pulley.

[ Fig. 30 ]

be fixed

be fixed

①

②

③

②

①

③

↓

↑

↓

↑

Loading...

Loading...