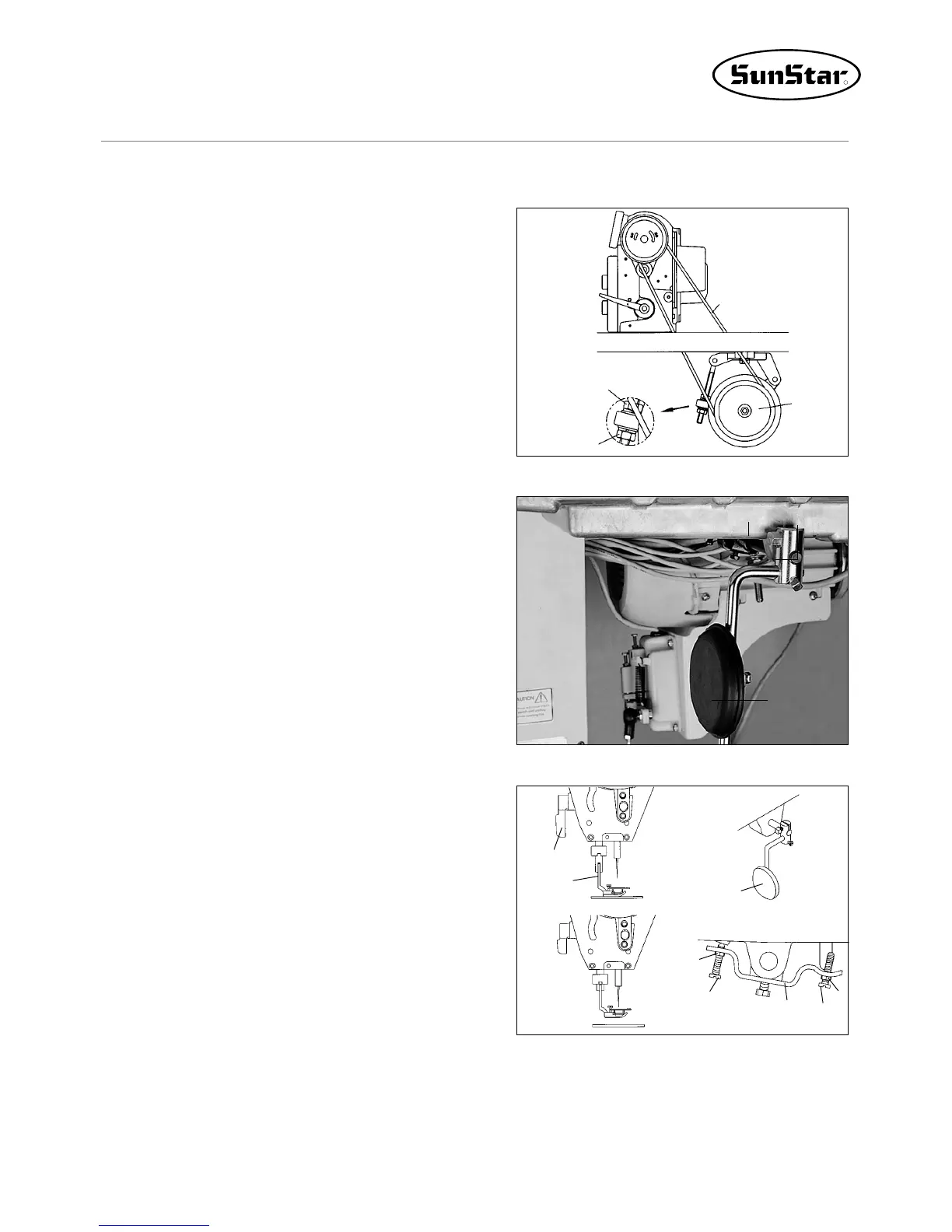

[ Fig. 5 ]

F. After connecting V belt, fully unfasten the fixing nut ①, ②

to up and down, tension occurs to belt by self weight of

motor ③. On this condition, fasten the fixing nut① first

and the fixing nut ② tightly.

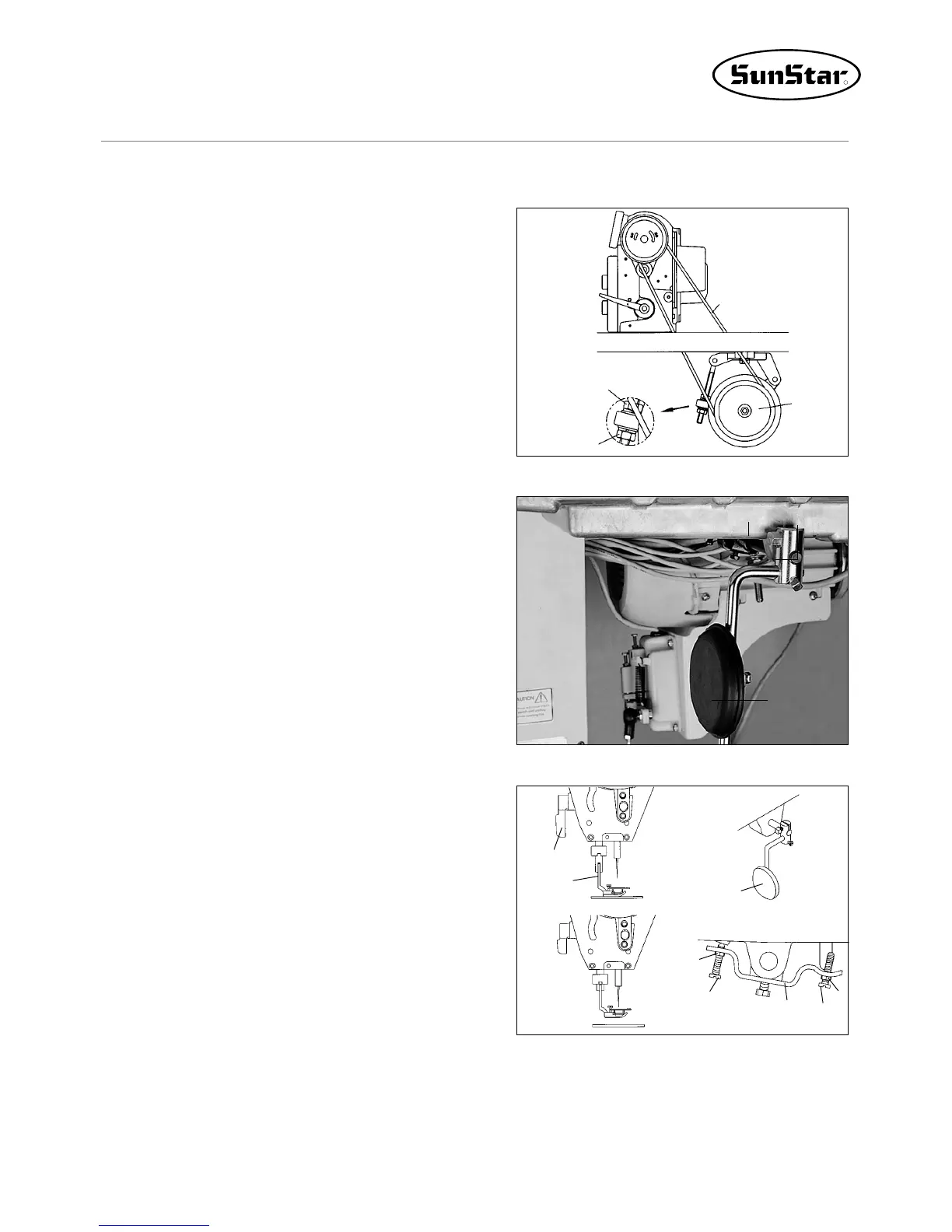

[ Fig. 6 ]

A. Insert the presser foot lifter pad (group) ① packed in the

accessory box into control body shaft ② of oil fan.

B. After unfastening the volt ③ and deciding the location

convenient of operation for presser foot lifter, tightly

fasten again.

4) Installation of Presser Foot Lifter Pad

③②

①

[ Fig. 7 ]

A. Put down the feed dog lower than top of the needle plate

by turning the pulley.

B. Put down the presser foot②to presser bar lifter①.

C. Unfasten nut③.

D. Adjust by turning the joint screw ⑥that operation olume

(space) of control body ⑤ should become about 2mm

when lightly press the presser foot lifter pad (group)④ by

hands.

E. After adjustment, joint the nut③tightly.

F. Unfasten the nut⑦.

G. Adjust by rotating joint screw⑧ that joint screw⑧

becomes about 7mm higher than control body⑤.

H. Adjust by turning joint screw⑧ that presser foot②

becomes within 10mm than needle plate when hardly

pressed the presser foot lifter pad (group) ④.

I. After adjustment, joint the nut⑦tightly.

①

②

④

③

⑥

⑤

⑧

⑦

5) Adjustment of Presser Foot Lifter (group) Pad

①

②

④

③

Loading...

Loading...