23

88

Adjustment of Sewing Machine

1) Adjustment of Needle Thread Tension

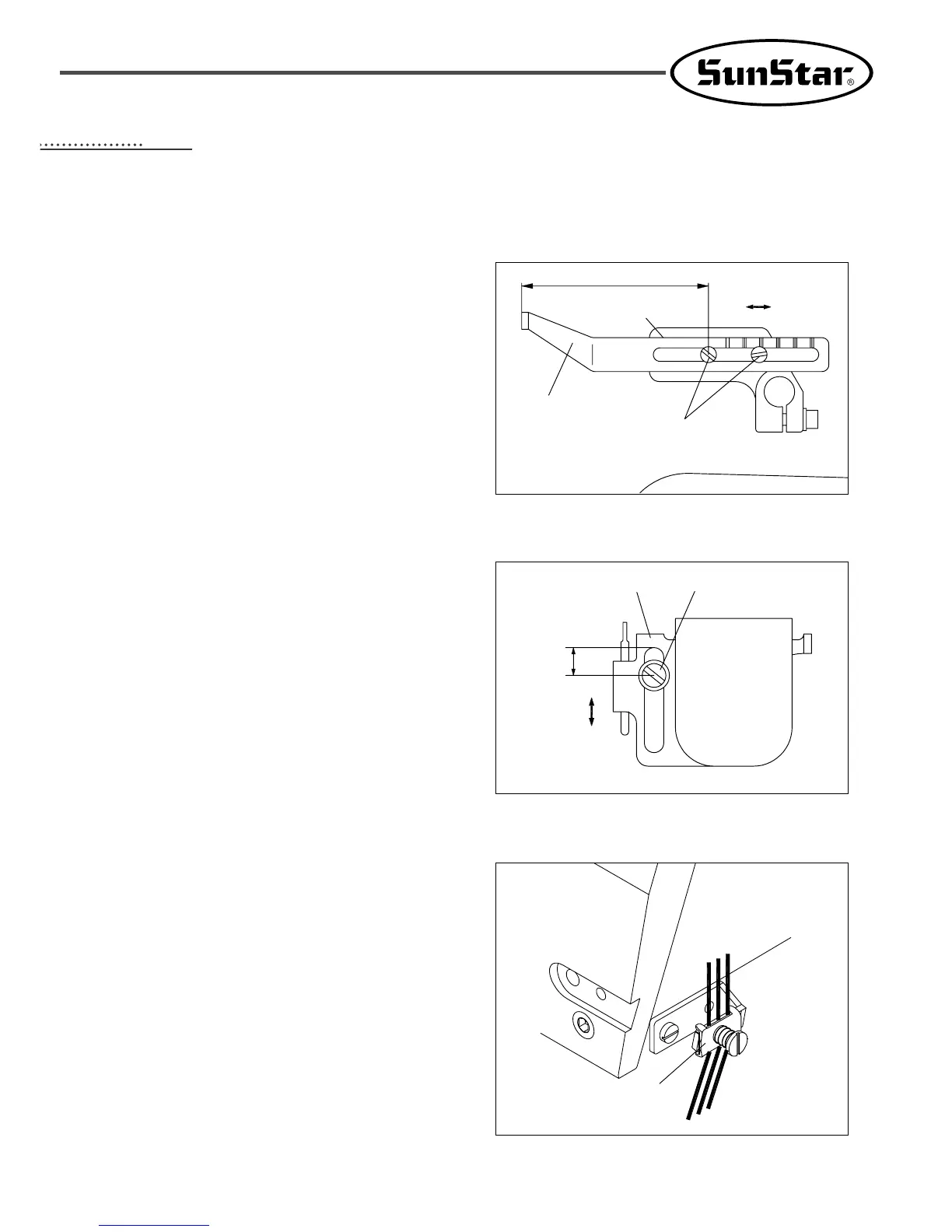

When the tip of [the needle thread take-up①] is 52mm

away from the center of [the screw②], and the needle bar is

at the highest position, [Part a] of [the needle thread take-up

①] becomes horizontal.

This is a standard needle thread tension.

If you desire to raise the needle thread tension, move [the

needle thread take-up①] in the Y direction. If you desire to

lower the needle thread tension, move the take-up in the X

direction.

To make this adjustment, loosen [the screw②].

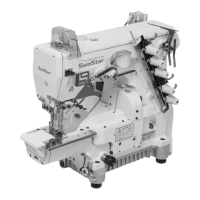

If more adjustment is needed, loosen [the screw③] and

check the thread tension, while moving the position of [the

thread eyelet④]

When the thread eyelet is moved in the Y direction, the

tread tension will increase. When it is moved in the X

direction, the thread tension will decrease.

The standard setting is to set the distance between the

middle of [the screw③] and the upper tip of [the thread

eyelet④] at 8mm.

[ Figure 29 ]

①

[ Figure 30 ]

③

④

②

52mm

3mm

Y

Y

a

X

X

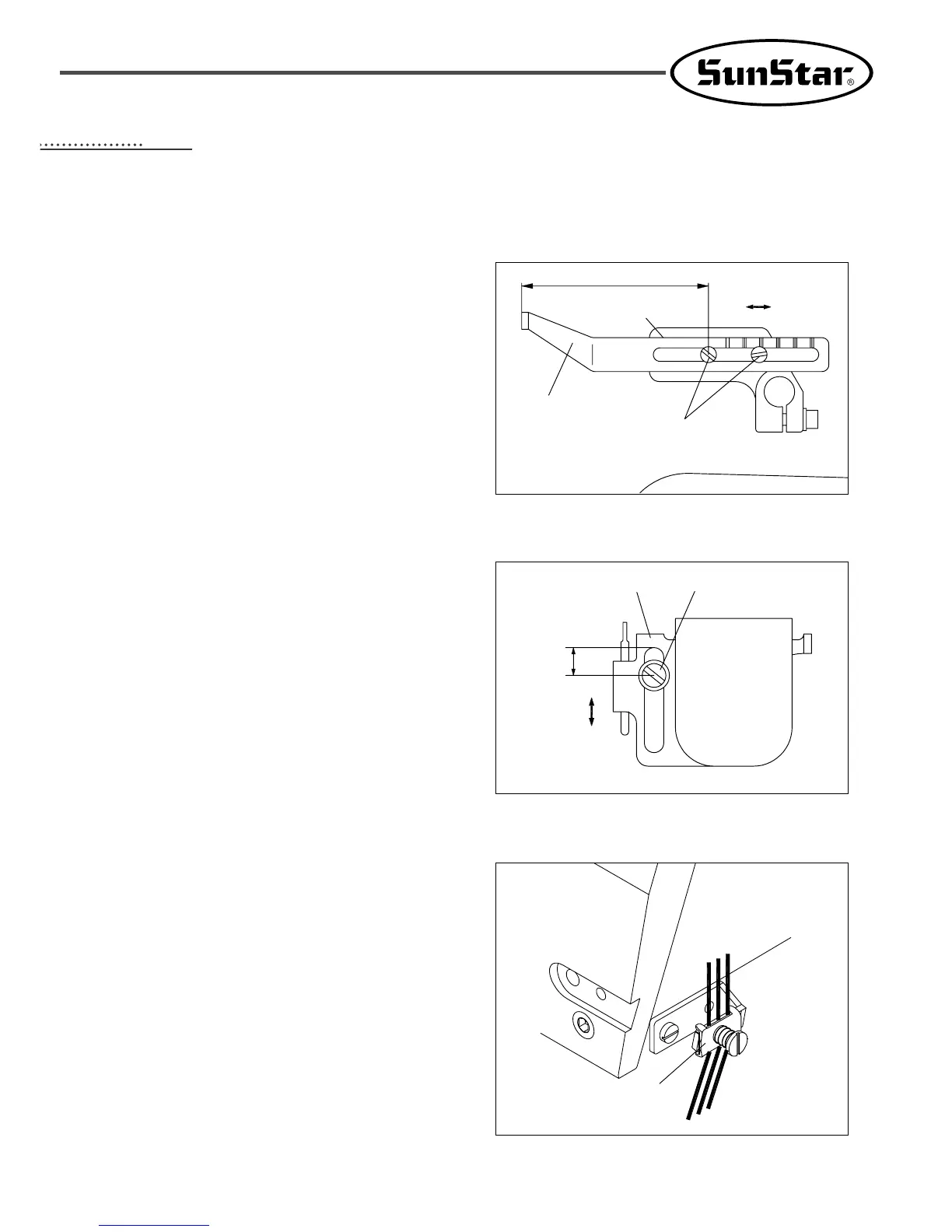

For some types of threads, looping is not an easy thing to

do. Wrong loops may make it difficult for the looper to pass

needle thread loop and cause skipped stitches.

In such case, pull the needle thread through the auxiliary

tension-adjusting device of the needle thread ① as shown in

figure 31.

[ Figure 31 ]

①

Loading...

Loading...