24

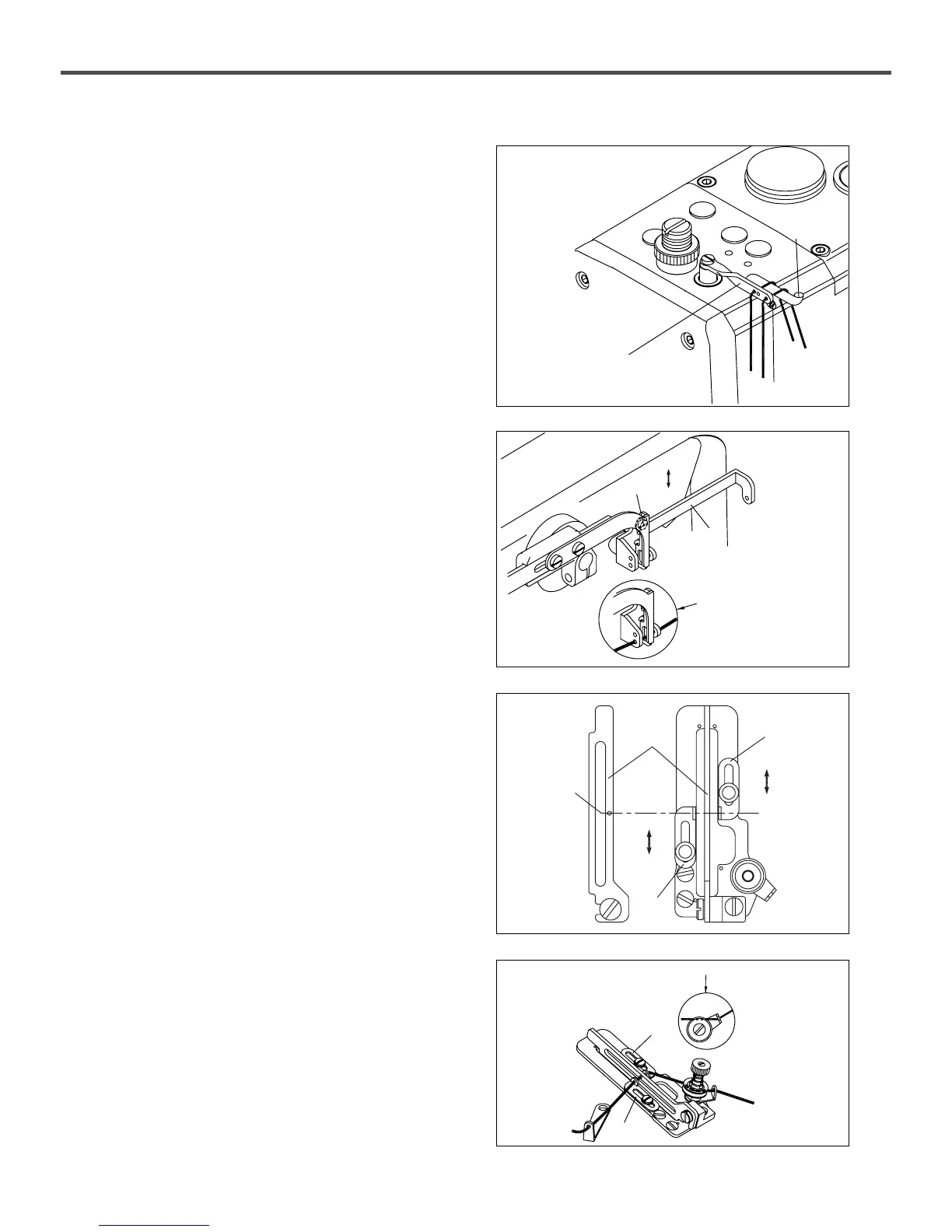

Use the needle thread guide ③ when using stretchable

threads such as synthetic thread and the loop of needle

thread is unstable.

It is a standard setting to bring the center of the needle hole

of the needle bar take up ② against the upper side of the

needle thread guide when the needle bar is at its lowest

position.

The height of the needle bar guide can be adjusted by

loosening the screw ④.

(refer to figure 32)

[ Figure 32 ]

③

②

②

①

⑤

less

less

much

much

⑥

⑥

⑦

⑦

for woolly thread

for woolly thread

④

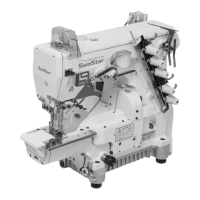

2) Adjustment of Top Cover Thread Tension

When [the top cover thread eyelet(Right)①] is moved up in

the X direction, the take-up volume decreases. When it is

moved down in the opposite way, the take-up volume

increases.

When an elastic thread such as woolly thread is used as the

top cover thread, loosen [the screw②] to move down [the

top cover thread eyelet (Right)①] in the Y direction. This

time make sure that the top cover thread passes through the

bottom hole as in the right figure.

[ Figure 33 ]

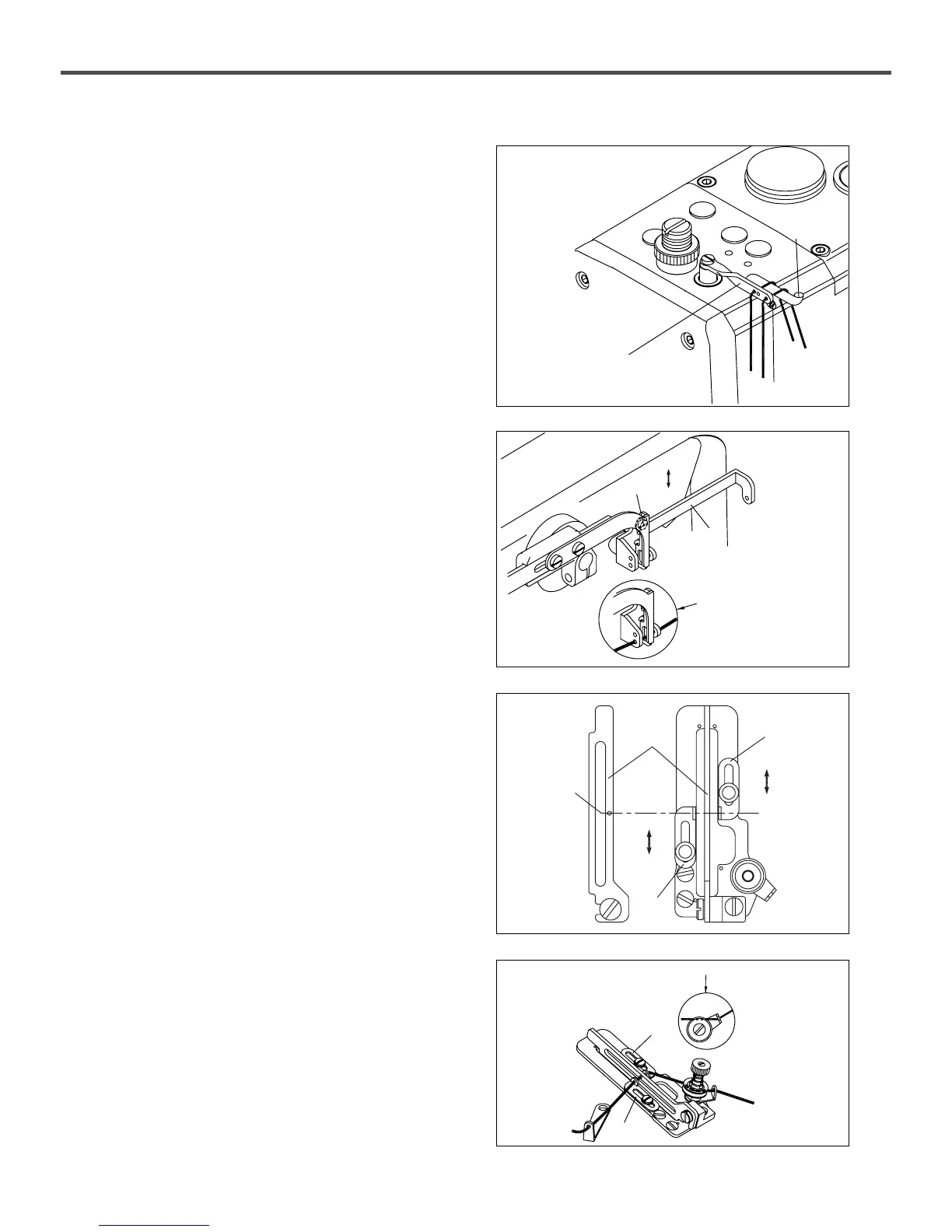

3) Adjustment of the Looper Thread Tension

The figure shows the looper thread take-up.

The standard setting is to place the thread holes of [the

looper thread guide⑥,⑦] at [Mark X] on [the looper thread

cast-off plate⑤].

To increase the length of loose thread, loosen the fixing

screws for [the looper thread guides⑥,⑦], and move them

forward and then fix them. To reduce the length of loose

thread, move the looper thread guides backward and fix

them.

Note :

If the looper thread’s loose thread is too long, it might cause

stitch skips. Make sure that the looper thread’s loose thread

is not too long.

When using woolly thread, move [the looper thread guides

⑥,⑦] forward to the maximum and make sure that the

thread doesn’t pass through [the supplementary tension disc

(H)].

[ Figure 34 ]

[ Figure 35 ]

Y

X

X

Loading...

Loading...